Vehicle shock absorber working cylinder expanding tool

A shock absorber and working cylinder technology, applied in transportation and packaging, forming tools, manufacturing tools, etc., can solve the problems of responsible operation process, low production efficiency, unstable quality, etc., to ensure safe use, high processing accuracy, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

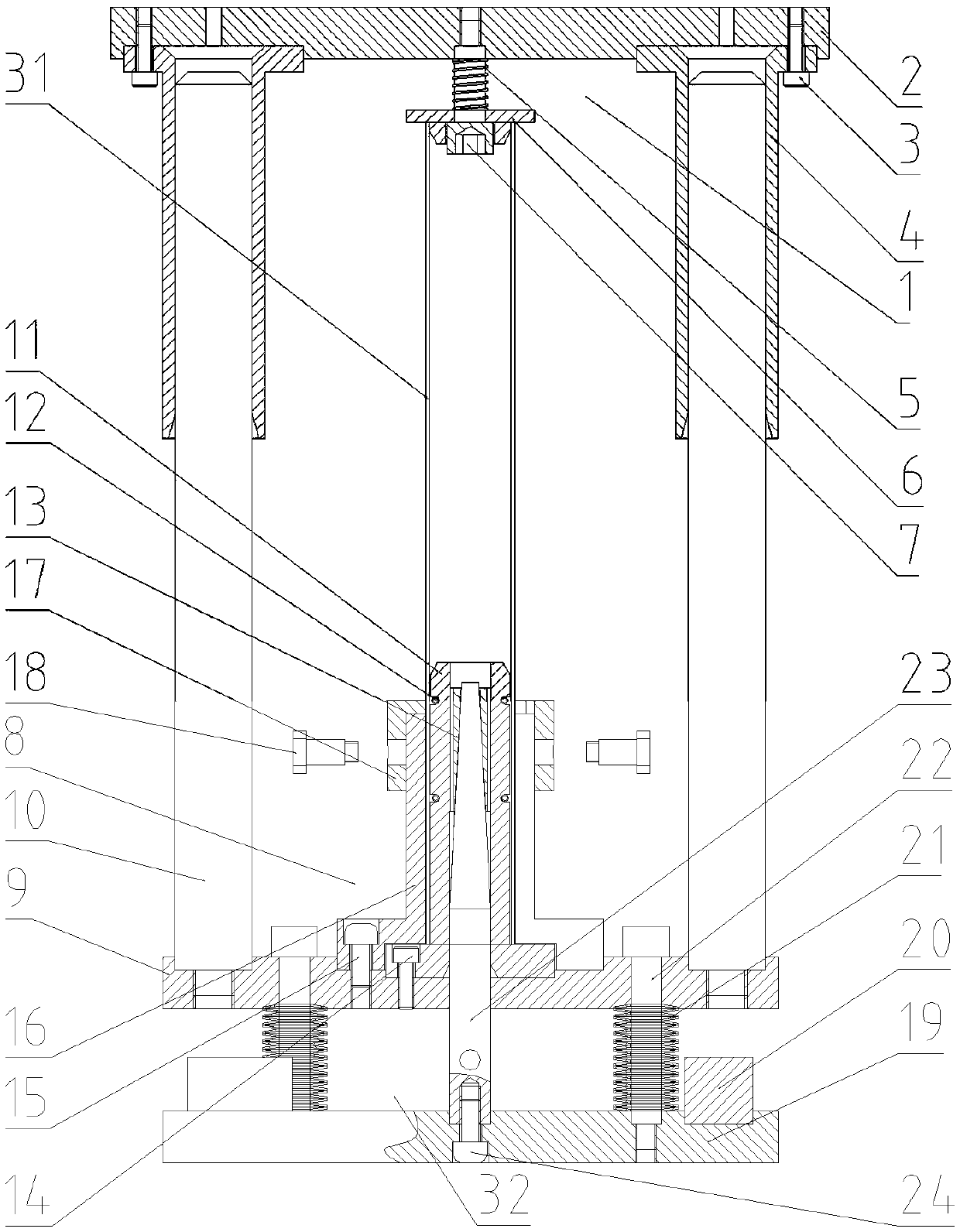

[0034] Such as Figure 1-4 As shown, an automobile shock absorber working cylinder expansion package tooling includes an upper die set 1, a lower die set 8, and a bottom die set 32.

[0035] The upper module 1 includes a top plate 2, a guide sleeve 4, and a centering head 6. The guide sleeve 4 is fixed on the lower surface of both ends of the top plate 2 by a screw one 3, and the centering head 6 is sleeved on the screw two 7. And can slide up and down, the second screw 7 is screwed in the center of the lower surface of the top plate 2, a compression spring 5 is set between the centering head 6 and the top plate 2, the second screw 7 is 10 cm long, the The effective stroke of compression spring 5 is 6 centimetres.

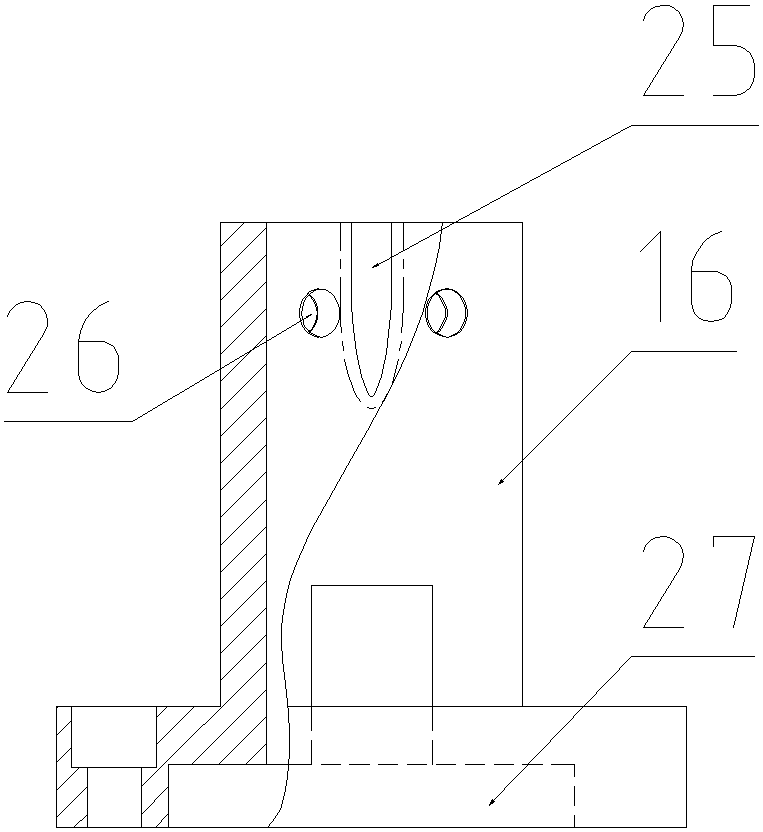

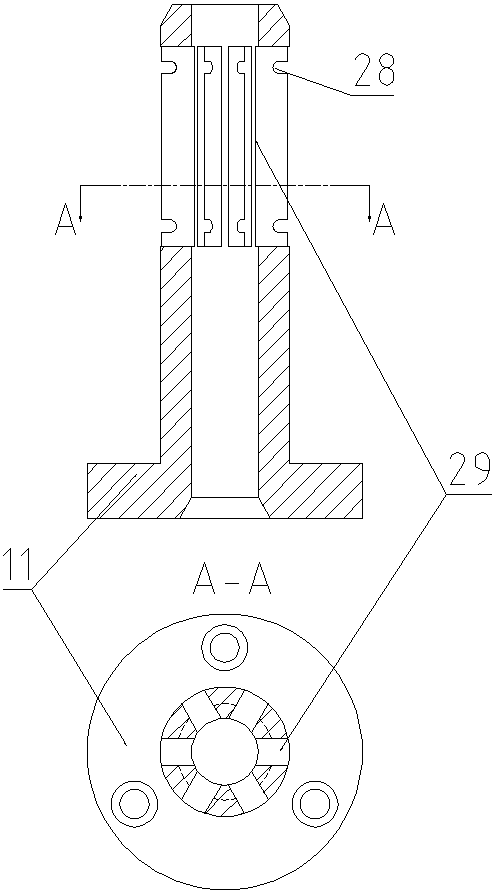

[0036] Described lower mold group 8 comprises connecting plate 9, column 10, punch seat 11, punch 13, punch cover 17, die 16, and the lower end of described column 10 is screwed on the two ends of described connecting plate 9, The upper end of the column 10 is sl...

Embodiment 2

[0048] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that a through hole is set at the corresponding position of the top plate 2 in the center of the inner hole top surface of the guide sleeve 4, and the inner cavity of the guide sleeve 4 passes through the through hole to connect with the outside of the hole. In communication, when the guide sleeve 4 and the column 10 move relative to each other, adjusting the pressure in the inner cavity of the guide sleeve 4 can make the column 10 move more smoothly in the inner hole of the guide sleeve 4 .

Embodiment 3

[0050] The structure of this embodiment is basically the same as that of Embodiment 1, the difference being that the top edge of the punch seat 11 is chamfered at 45 degrees, which facilitates the positioning of the inner hole of the working cylinder 31 and prevents damage to the inner wall of the working cylinder 31 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com