Method for preparing transparent dealcoholized single-component room temperature vulcanized silicone rubber

A technology of room temperature vulcanization and dealcoholization, which is applied in the direction of chemical instruments and methods, adhesives, and other chemical processes. Improves storage stability and prevents gelation of the rubber compound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

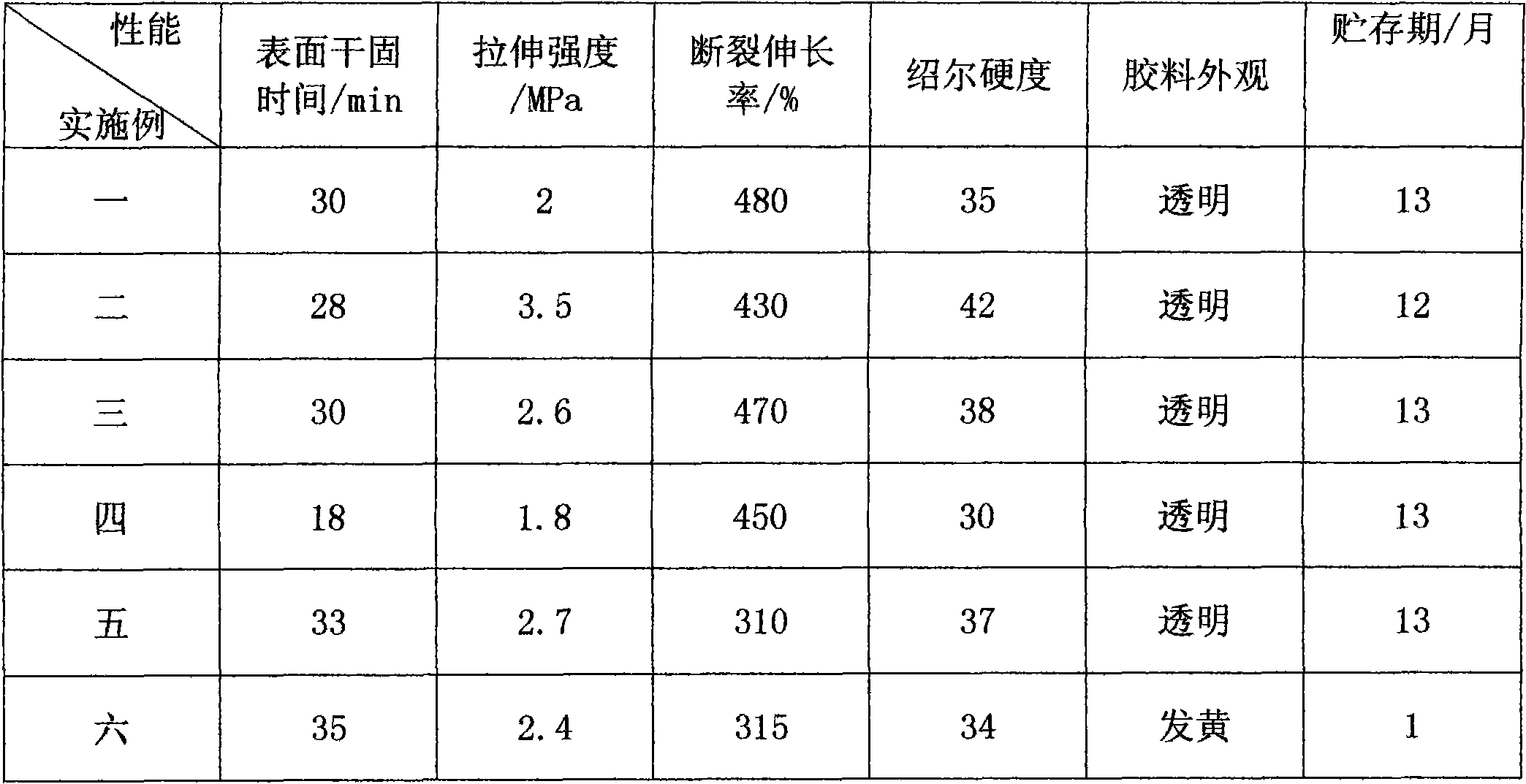

Examples

preparation example Construction

[0068] The preparation method of the transparent dealcoholized one-component RTV silicone rubber of the present invention comprises the following steps:

[0069] 1. Prepare the composition raw material formula of the following weight percentage

[0070] (a) 80% to 90% α, ω-dihydroxy polydimethylsiloxane;

[0071] (b) 1% to 15% white carbon black reinforcing filler;

[0072] (c) 1% to 5% siloxane crosslinking agent;

[0073] (d) 0.01%~2% TiOSi catalyst;

[0074] (e) 0.01% to 3% organic tin catalyst;

[0075] (f) 5% to 10% alkane mixture plasticizer;

[0076] (g) 0.01%~5% silane coupling agent;

[0077] Among them, the molecular weight of α, ω-dihydroxy polydimethylsiloxane is between 3000-100000g / mol, and the dynamic viscosity is 10000-100000Pa·s; the reinforcing filler is white carbon black with different specific surface areas; siloxane crosslinking The general formula of the agent is: R 1 4-n Si(OR 2 ) n (0≤n≤4), where R 1 is a linear or branched saturated or unsatu...

Embodiment 1

[0082] 1) α, ω-Dihydroxypolydimethylsiloxane 84%;

[0083] 2) White carbon black reinforcing filler 10%;

[0084] 3) 3% siloxane compound;

[0085] 4) TiOSi 0.1%;

[0086] 5) Organic tin catalyst 0.04%;

[0087] 6) alkane mixture plasticizer 2.7%;

Embodiment 2

[0090] 1) α, ω-Dihydroxypolydimethylsiloxane 78%;

[0091] 2) White carbon black reinforcing filler 14%;

[0092] 3) 3% siloxane compound;

[0093] 4) TiOSi 0.1%;

[0094] 5) Organic tin catalyst 0.04%;

[0095] 6) 4.7% of alkane mixture plasticizer;

[0096] 7) Silane coupling agent 0.16%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com