Method for separating and enriching trace lead in substrate

A technology of separation, enrichment and matrix, applied in the preparation of test samples, etc., can solve the problems of unguaranteed recovery rate and reproducibility of lead, difficulty in guaranteeing the effect of separation and enrichment, cumbersome steps of enrichment and separation, etc., to achieve easy purchase , low price, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

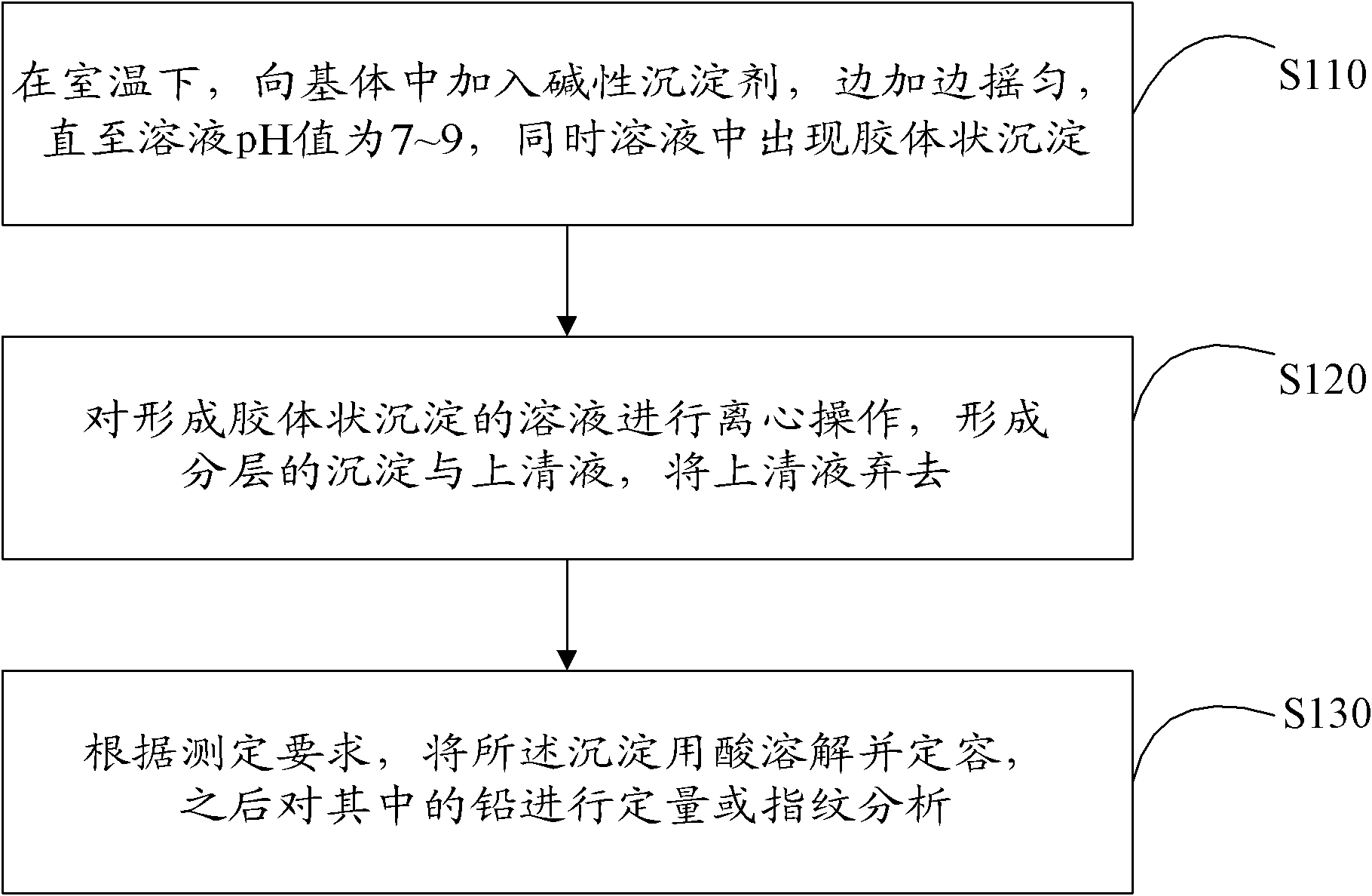

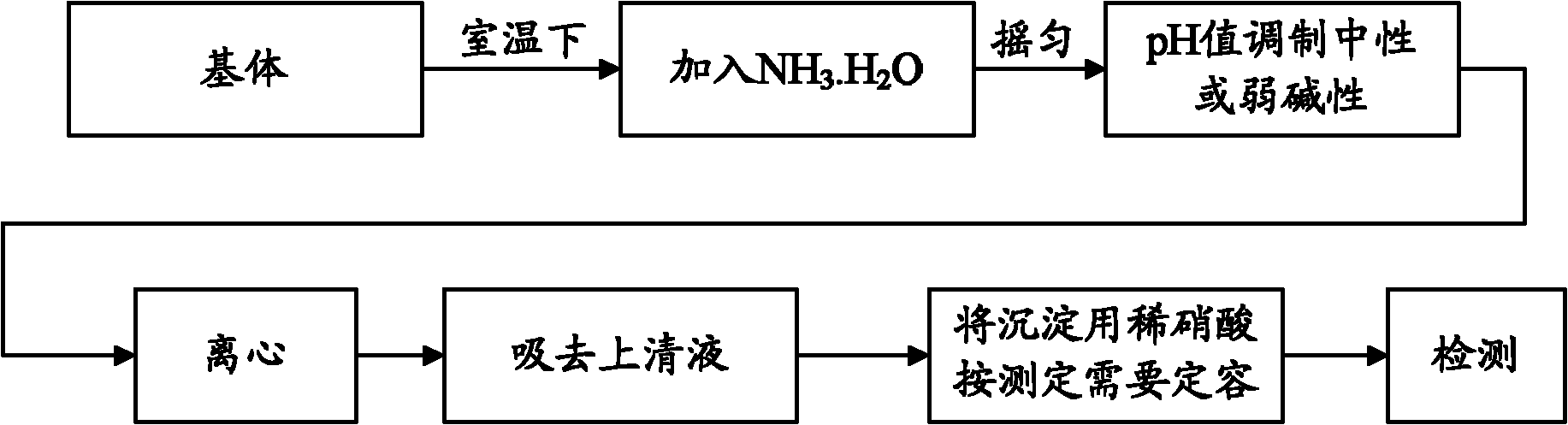

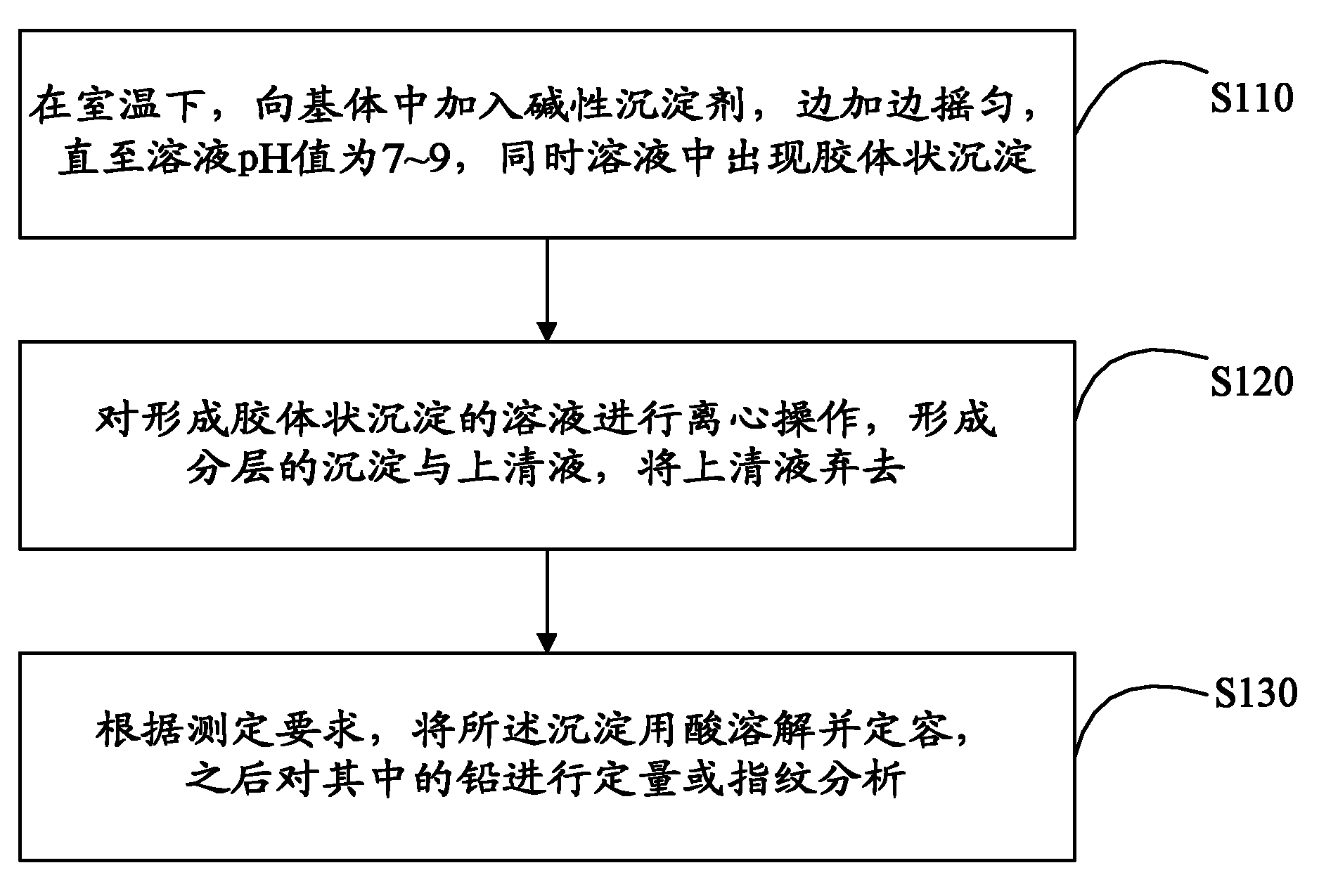

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0017] First, lead fingerprints, digestion solutions, and matrices are described.

[0018] ●Lead fingerprints Lead in nature is 204 Pb, 206 Pb, 207 Pb, 208 Pb exists in four isotopic forms, and lead from different sources has different isotopic compositions, which do not change with changes in physical, chemical, and biological conditions. Three independent isotopic ratios can be formed by comparing the four isotopic abundances, which are called "lead fingerprints".

[0019] ●Digestion solution: Digestion is a method of destroying organic matter or reducing substances in the sample by using acid or lye and heating. This method can destroy all organic and reducing substances and thermally unstable substances in various samples...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com