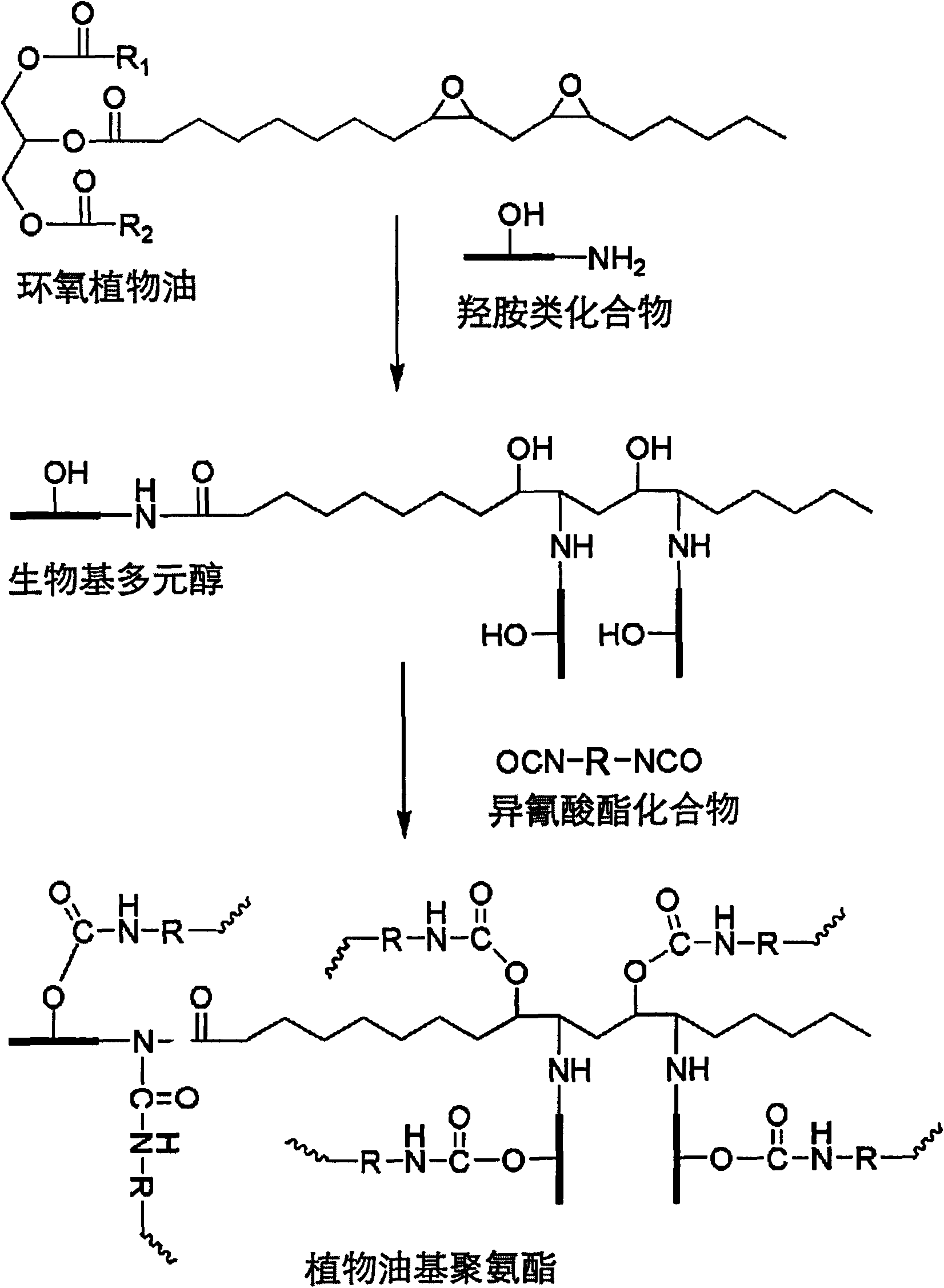

Preparation method of organism-based polyalcohol based on epoxidized plant oil and hydroxylamine compound

A bio-based polyol and epoxy vegetable oil technology, which is applied in the preparation of organic compounds, carboxylic acid amide preparation, chemical instruments and methods, etc., can solve the problem of high cost of industrial use of ozone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

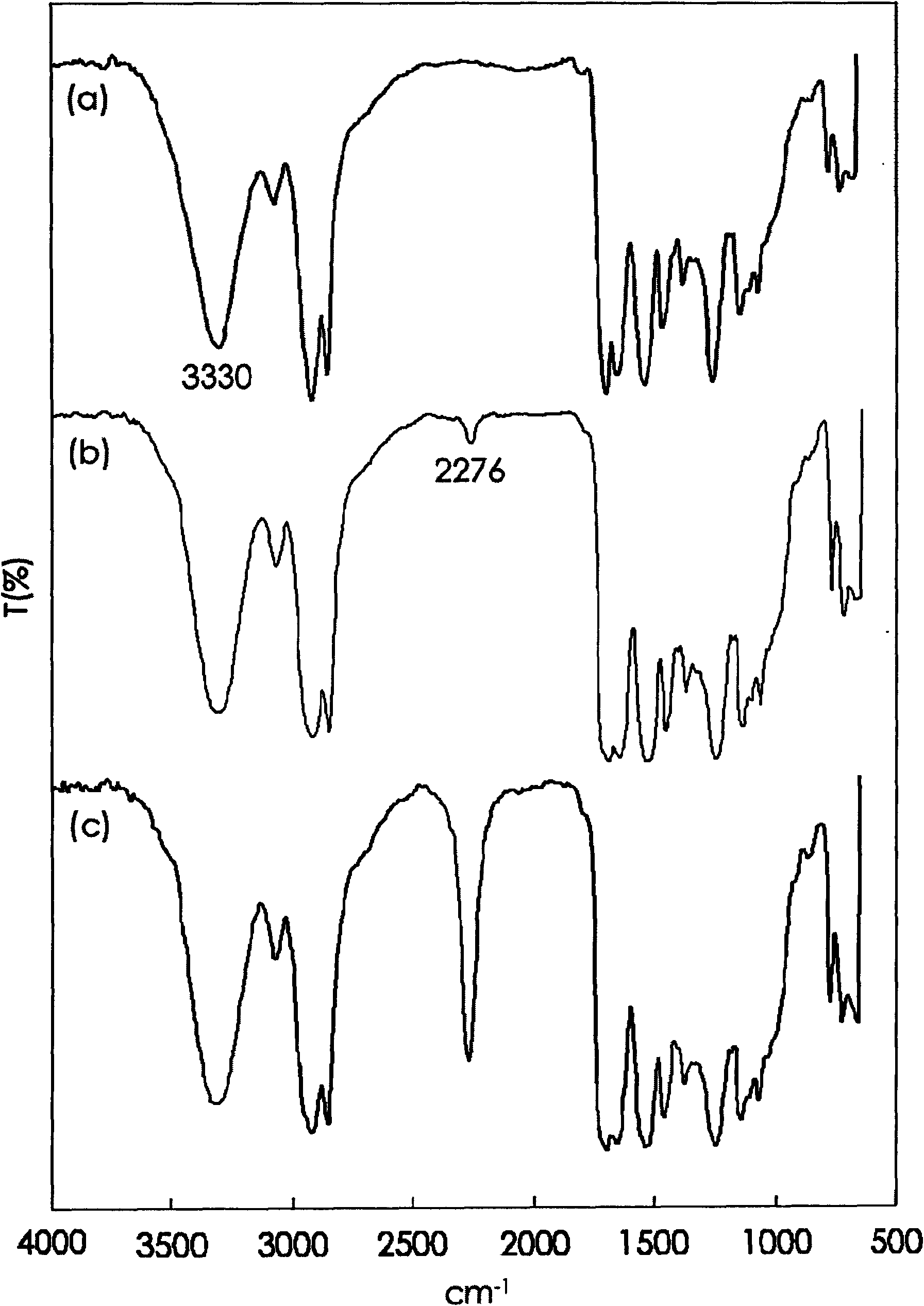

Method used

Image

Examples

Embodiment 1

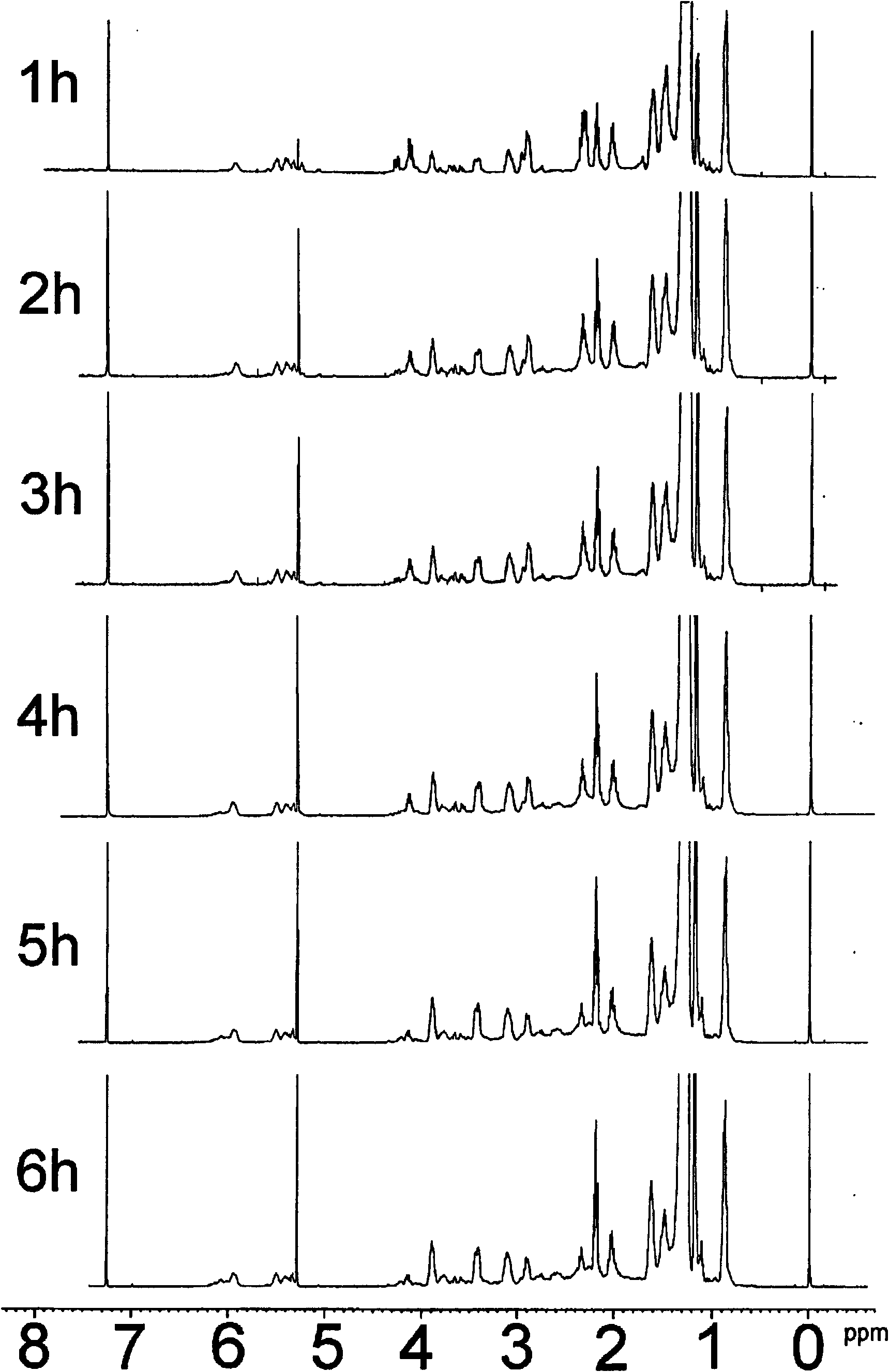

[0027] In a 250ml reactor, 25g of epoxidized soybean oil and 16g of 2-hydroxypropylamine were added, the above mixture was stirred evenly, and the temperature was raised to 90°C, and the stirring was continued, and the reaction was carried out for 24h. Then the reaction system was washed with high-purity water to remove unreacted 2-hydroxypropylamine, and the water was removed by rotary evaporation to obtain a viscous liquid. Add 3.7% hydrochloric acid to make the system weakly acidic, stir the system at 25°C for 30 minutes, then add 10% aqueous sodium hydroxide solution to make the system weakly alkaline. Add 250 mL of chloroform to extract the reaction product, and wash the organic phase with water for more than three times, each time with 250 mL of water. The organic phase is taken out, and the organic solvent is removed by a rotary evaporator to obtain a polyol product. product of 1 H NMR spectrum as figure 2 shown.

Embodiment 2

[0029] In a 250ml reactor, add 25g of epoxidized soybean oil and 20g of 2-hydroxypropylamine, stir the above mixture evenly, and raise the temperature to 90°C, continue stirring, and the reaction proceeds for 24h. Then the reaction system was washed with high-purity water to remove unreacted 2-hydroxypropylamine, and the water was removed by rotary evaporation to obtain a viscous liquid. Add acetic acid for treatment to make the system weakly acidic, stir the system at 75°C for one hour, then add 10% aqueous sodium hydroxide solution to make the system weakly alkaline. Add 250 mL of chloroform to extract the reaction product, and wash the organic phase with water for more than three times, each time with 250 mL of water. The organic phase is taken out, and the organic solvent is removed by a rotary evaporator to obtain a polyol product.

Embodiment 3

[0031] In a 250ml reactor, 25g of epoxidized soybean oil and 12g of ethanolamine were added, the above mixture was stirred evenly, and the temperature was raised to 90°C, stirring was continued, and the reaction was carried out for 24h. Then the reaction system was washed with high-purity water to remove unreacted ethanolamine, and the water was removed by rotary evaporation to obtain a viscous liquid. Add 2% benzene methanesulfonic acid to make the system weakly acidic, stir the system at 75°C for one hour, then add 10% potassium hydroxide aqueous solution to make the system weakly alkaline. Add 250 mL of diethyl ether to extract the reaction product, and wash the organic phase with water for more than three times, each time with 250 mL of water. The organic phase is taken out, and the organic solvent is removed by a rotary evaporator to obtain a polyol product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com