Towing winch with automatic tensioning function and implementation method thereof

A towing winch and functional technology, which is applied to the towing operation field where the towing winch adopts the automatic tensioning function, can solve the problems of slow response speed, high energy consumption, poor stability, etc., and achieves increased braking torque, easy operation, Stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Example: braking force 1200N, load 1000N:

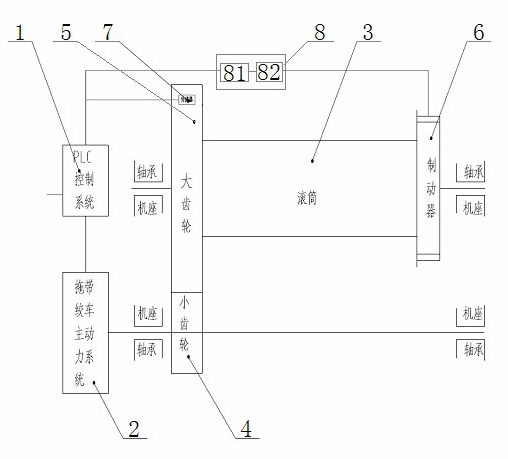

[0034] A method for realizing the above-mentioned tow cable winch with automatic tensioning function, the method for realizing includes the following steps in sequence:

[0035] The first step: Initially start the PLC control system 1 to read the data of the speed sensor 7, the data transmitted by the data of the speed sensor 7 is 0, and then calculate the retractable length of the cable at this time as 0 according to the data, and set The calculated retractable length is used as the initial value;

[0036] Step 2: First select the working mode on the control panel of the towing winch as the automatic tensioning function, then set the maximum retractable length of the cable on the basis of the above initial value, and issue a brake control command, which is passed through the PLC The control system 1 reaches the brake control device 8 after processing, and then the brake control device 8 sets the braking force of the stepless...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com