Double-barrelled automatic slag adding machine

A technology of automatic slag feeding machine and feeding pipe, which is applied in the field of double-pipe automatic slag feeding machine, can solve the problems of high crushing rate of pipes and mold slag, easy wear of elbows and pipes, increase the width of slag feeding machine, etc., and achieve structural Compact, uniform slag addition, high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following further describes the present invention in conjunction with the accompanying drawings and specific embodiments, without limiting the scope of protection:

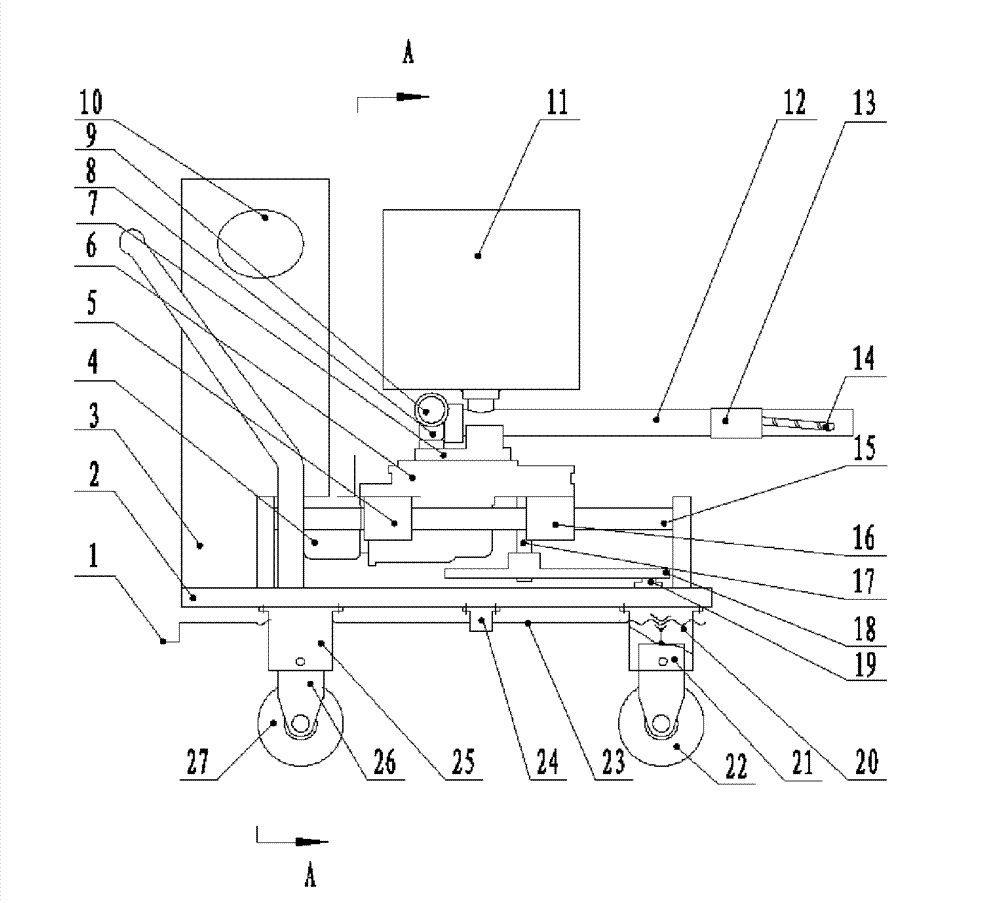

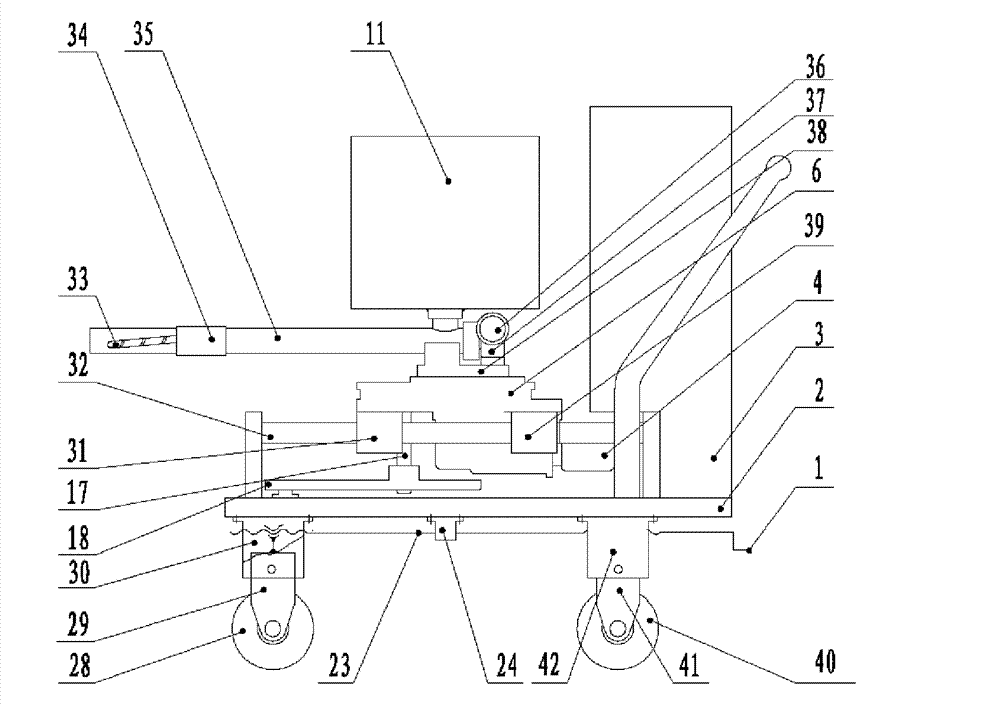

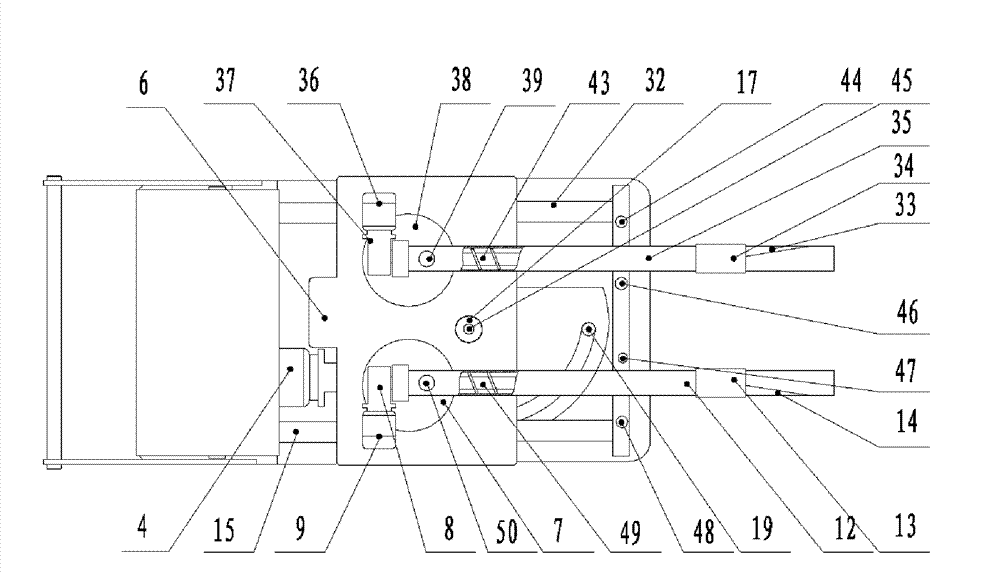

[0039] A double-pipe automatic slag adding machine, such as figure 1 , figure 2 , image 3 with Figure 4 As shown, it is composed of a frame, a slag adding system and an electronic control system; the slag adding system is installed in the front of the frame 2, and the electronic control system is installed in the rear of the frame 2.

[0040] The structure of the slag adding system is: the output shaft of the swing motor 4 is connected to the input shaft of the third reducer 6 through a coupling, and the first feed pipe swing output shaft and the second feed pipe swing output of the third reducer 6 The shafts are respectively keyed to the first conveying pipe support plate 7 and the second conveying pipe support plate 38. The first conveying pipe support plate 7 and the second conveying pipe support plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com