Brush component of vacuum cleaner

A technology for vacuum cleaners and brushes, applied in suction filters and other directions, can solve the problems of inability to effectively collect hair and pet hair, reduce the cleaning efficiency of vacuum cleaners, and reduce cleaning efficiency, achieve compact structure, improve dust collection efficiency, improve The effect of design freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

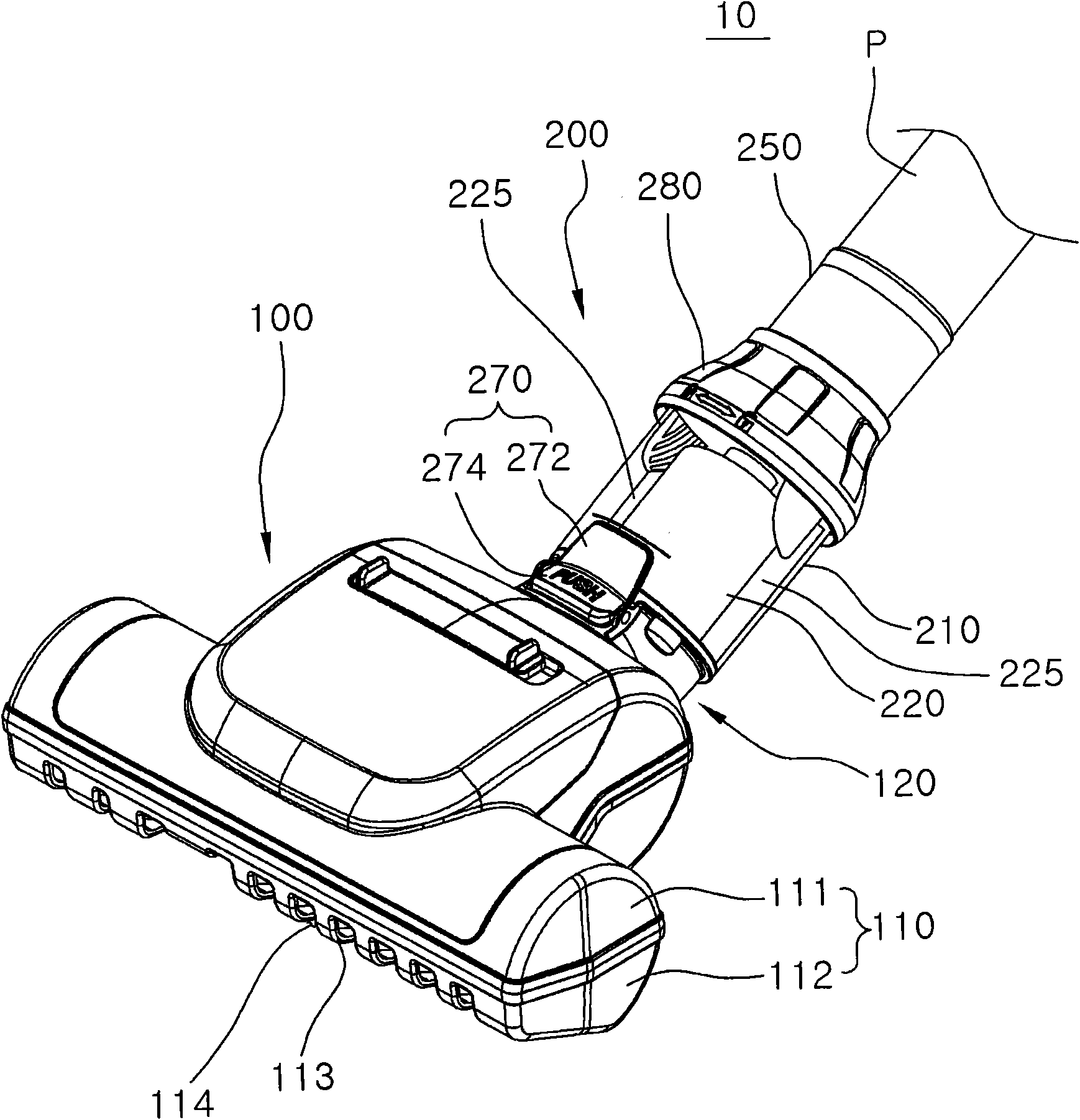

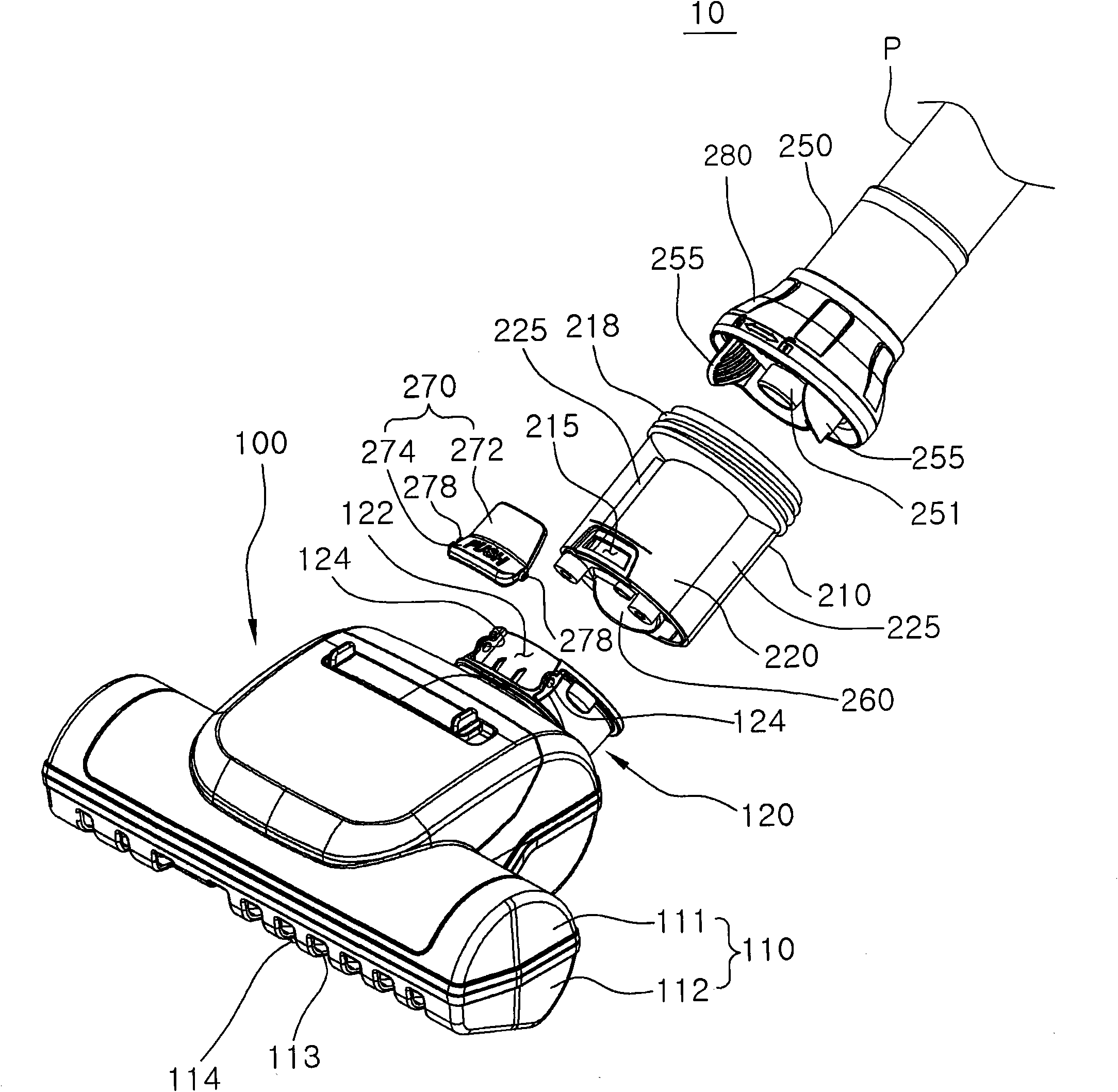

[0053] Below, refer to Figure 1 to Figure 7 A brush assembly 10 according to a first embodiment of the present invention is explained.

[0054] Such as Figure 1 to Figure 4 As shown, the brush assembly 10 according to the first embodiment of the present invention has a brush unit 100 and a cyclone dust collection unit 200 .

[0055] The brush unit 100 is for sucking air from the surface to be cleaned, and has a housing 110 , a neck 120 , a brush 130 , and a turbo fan 140 .

[0056] The housing 110 has an upper housing 111 and a lower housing 112 . These upper and lower casings 111 , 112 are combined with each other to form the inner space of the casing 110 .

[0057] The opened bottom of the lower case 112 is provided with a plurality of ribs 113 and formed with a plurality of bottom suction ports 114 . The dusty air on the surface to be cleaned is sucked into the inner space of the casing 110 through the bottom surface suction port 114 .

[0058] The neck 120 is a memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com