Tobacco bundle head loosening machine

A technology of unpacking machines and tobacco handles, which is applied in the fields of tobacco, tobacco preparation, application, etc., and can solve problems such as labor-consuming and time-consuming, failure to remove defective cigarettes and non-smoke inclusions, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

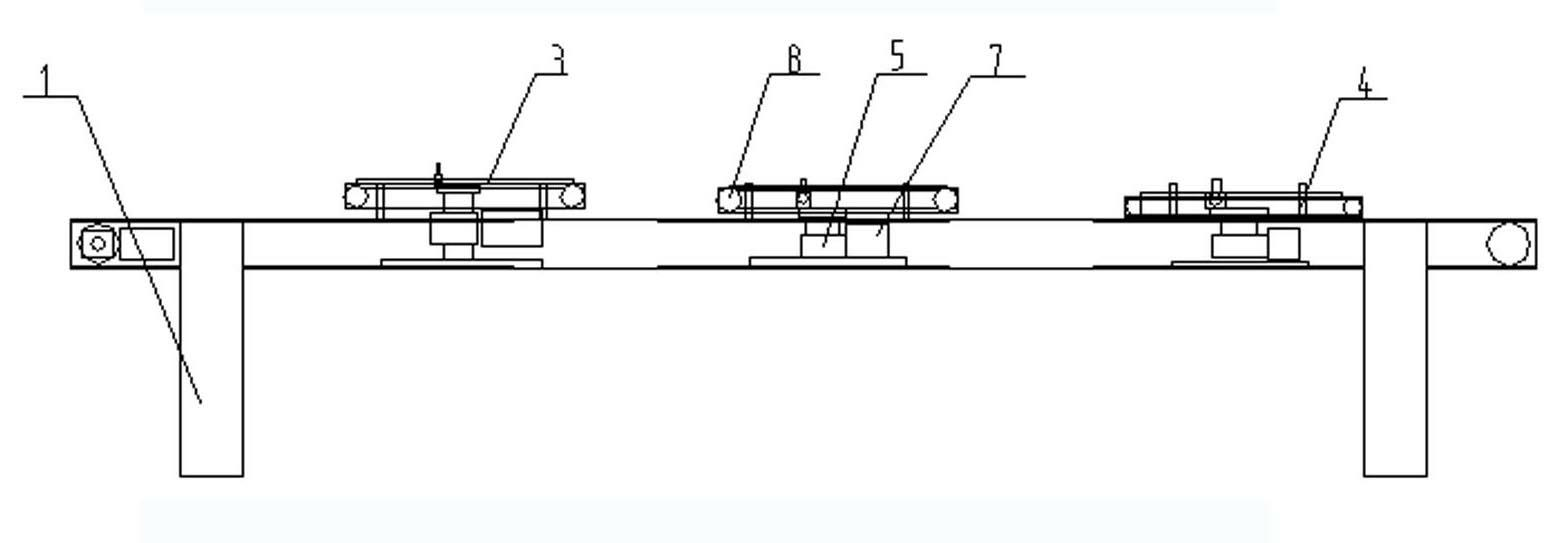

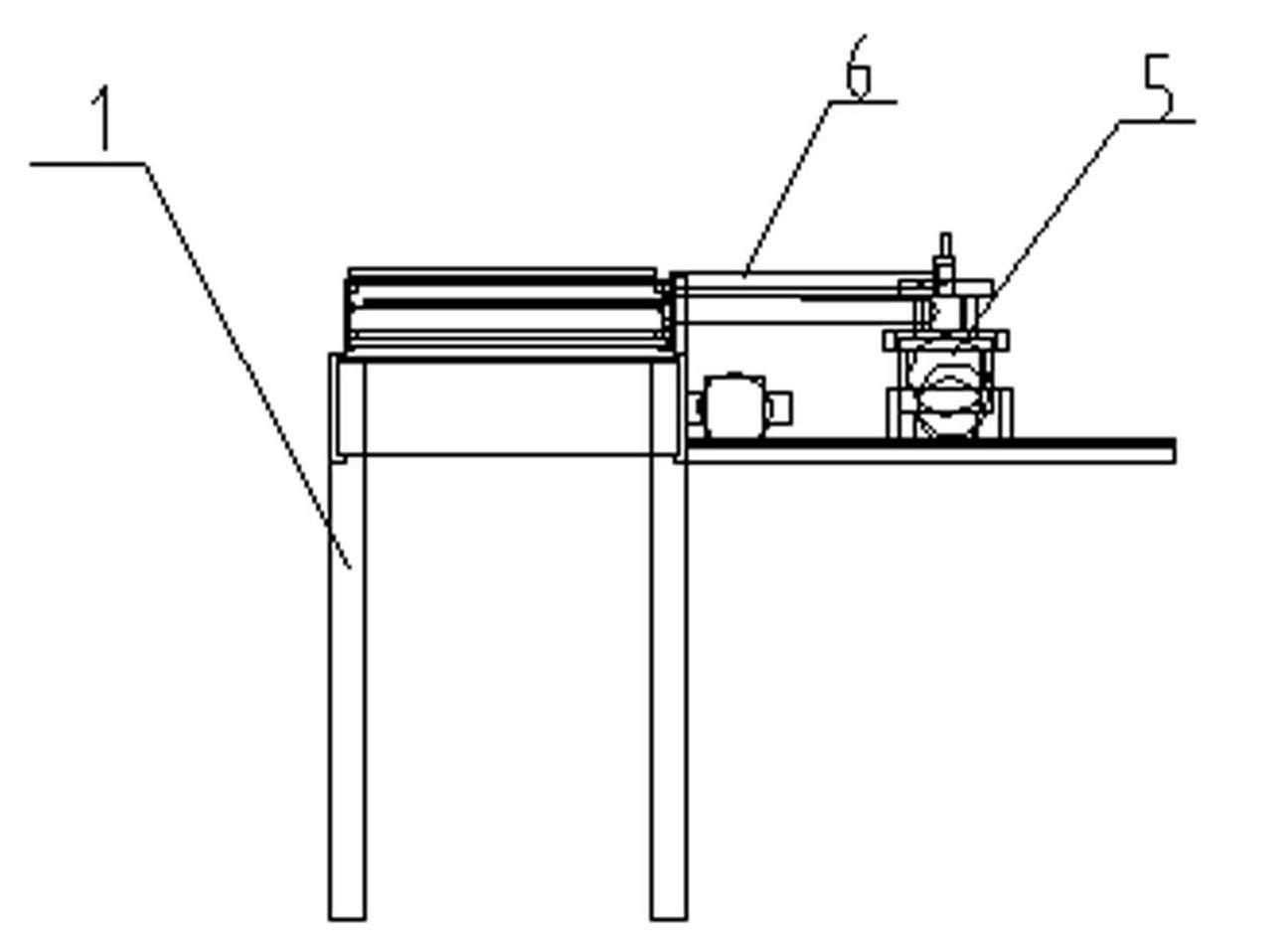

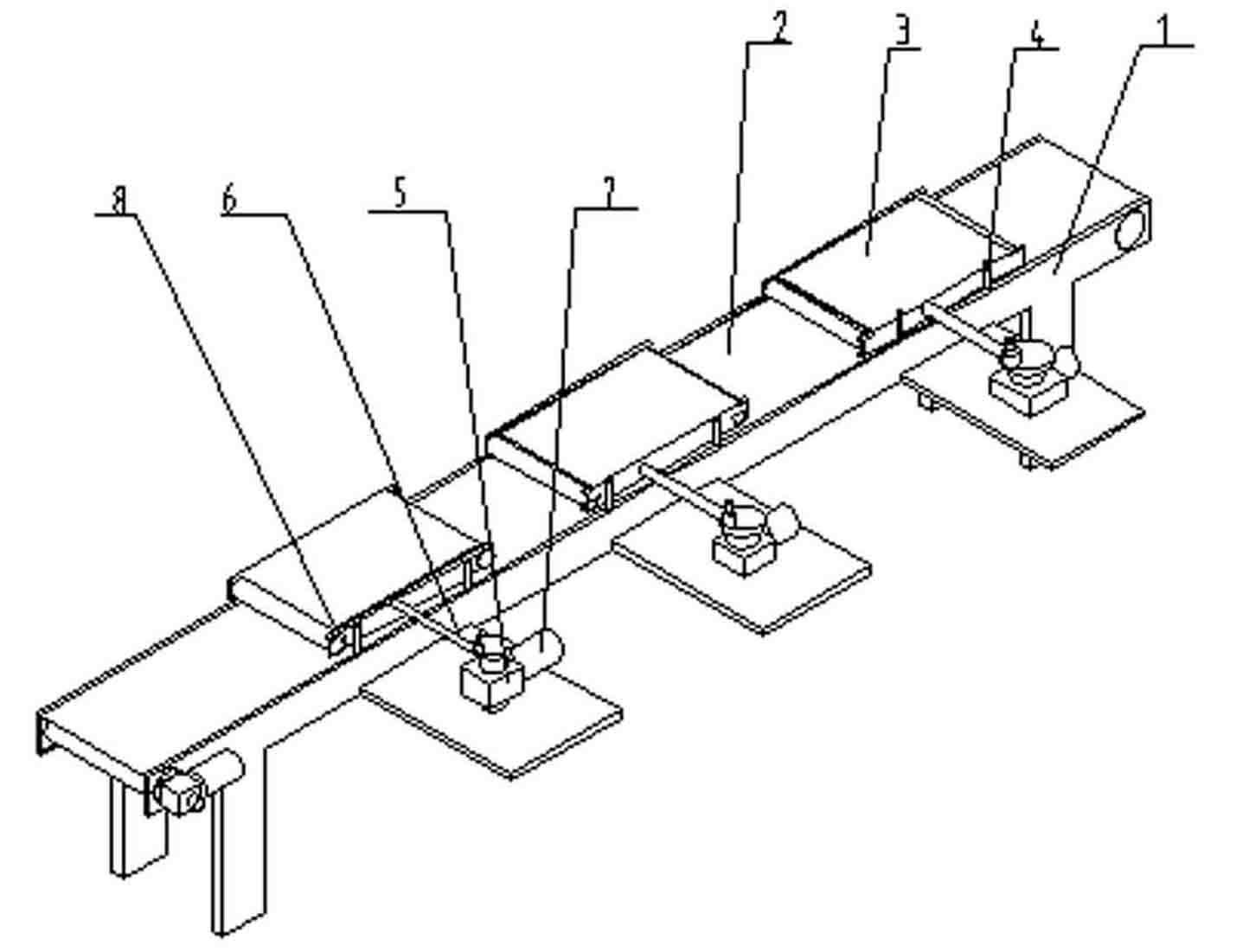

[0013] The cigarette holder kneading machine according to the present invention is composed of a frame 1, a conveying belt 2 and a disc type conveying belt 3, the conveying belt 2 is arranged on the frame 1, and the conveying belt 2 is a single conveying belt with friction The belt, the disc conveyor belt 3 is fixed above the conveyor belt 2 through the spring 4, and is connected with the eccentric disk 5 fixed on the frame 1 through the side rod 6, and the conveyor belt 2 and the eccentric wheel 5 are respectively connected with the Reduction motor 7 is connected, and grinding disc type conveying belt 3 is connected with electric drum 8, and the direction of rotation of conveying belt 2 is opposite to that of grinding disc formula conveying belt 3.

Embodiment 2

[0015] In the cigarette holder rubbing machine according to the present invention, the disc type conveyor belts 3 are divided into two groups, and the two groups of disc type conveyor belts are arranged equally with each other. The material flow direction is arranged in order from high to low. All the other are with embodiment 1.

Embodiment 3

[0017] Such as Figure 1-3 As shown, in the cigarette holder according to the present invention, there are three groups of grinding disc conveying belts 3, and the three groups of grinding disc conveying belts are arranged equally with each other. The spacing is arranged in order from high to low along the material flow direction. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com