Photovoltaic cell array with mechanical uncoupling of the cells from the carrier thereof

A technology of photovoltaic cells and arrays, applied in the direction of photovoltaic power generation, photovoltaic modules, support structures of photovoltaic modules, etc., which can solve problems such as impact, loss of effectiveness, and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

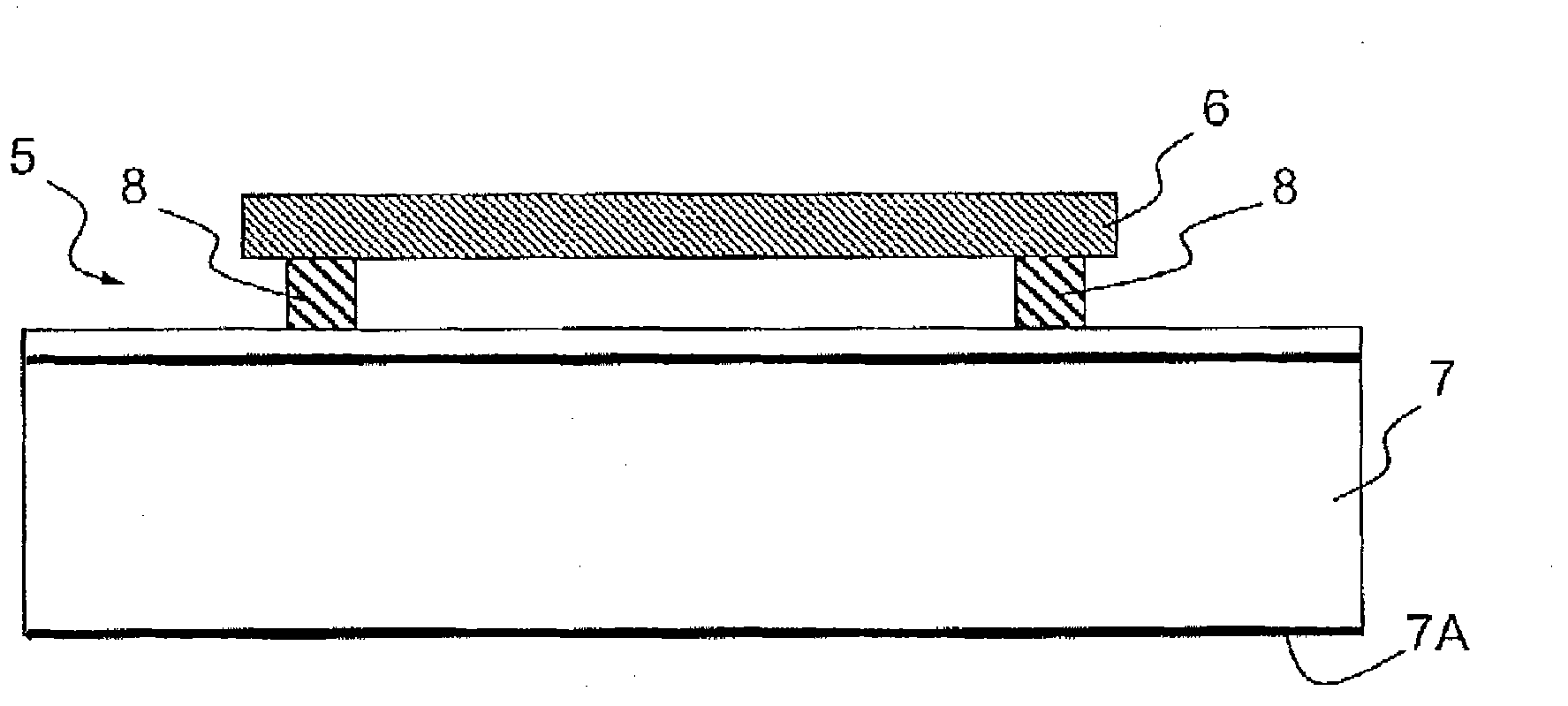

[0015] The present invention proposes a solution for reducing the mechanical coupling of the photovoltaic array of the solar generator relative to the supporting substrate of the photovoltaic array. In practice, photovoltaic cells are thin (tens of microns thick) and fragile. When a photovoltaic cell is bonded to a substrate, it undergoes geometric deformation due to vibrations, especially thermoelastic effects, which can lead to cell rupture. The invention consists of securing the battery by means of a flexible system, enabling the decoupling of the battery from the deformable part of the substrate, while ensuring sufficient radiative coupling of the battery towards the substrate, so as to avoid heating of the substrate in flight and loss of its effectiveness. This solution consists in the use of photovoltaic cells with high emissivity backsides (grid or Kaptoning backsides of Ge or Ag substrates are used) fixed on the substrate by means of Velcro.

[0016] figure 2 The ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com