Electromagnetic induction heating press-roller

A technology of electromagnetic induction heating and pressing roller, applied in induction heating, induction heating device and other directions, can solve the problems of reducing the heating efficiency of the heating roller, difficult to control the temperature accuracy of the heating roller, low heat transfer efficiency, etc. Heating efficiency, the effect of avoiding overheating of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

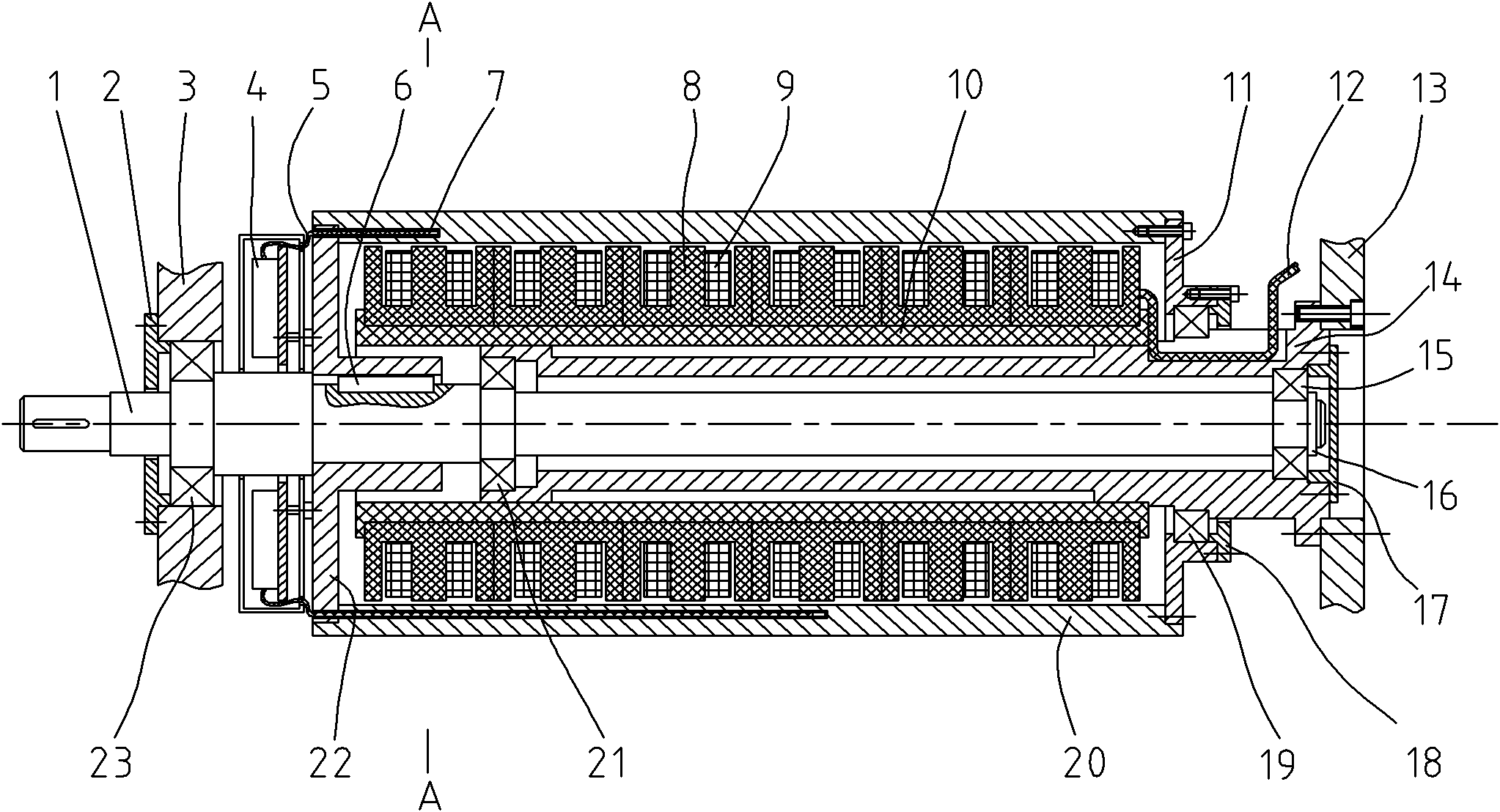

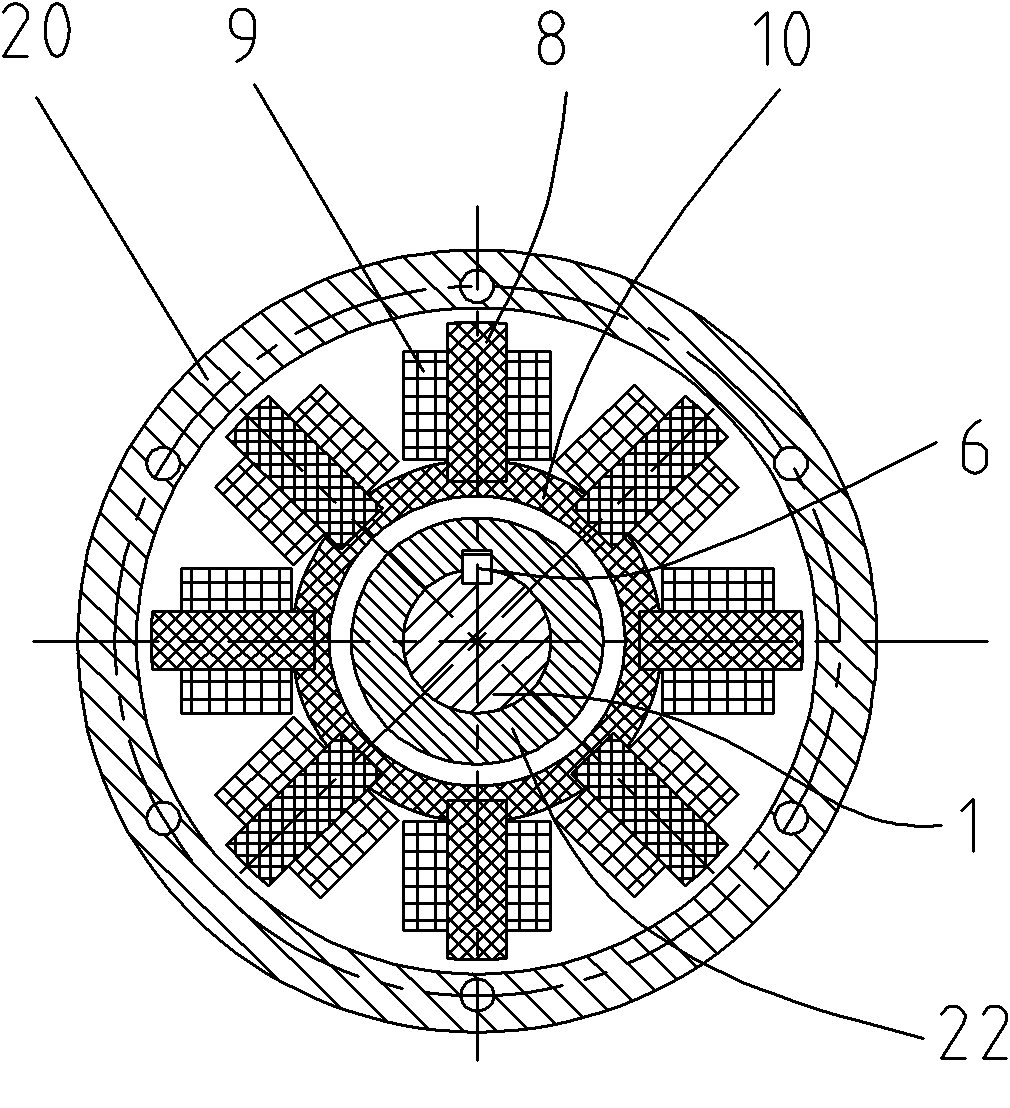

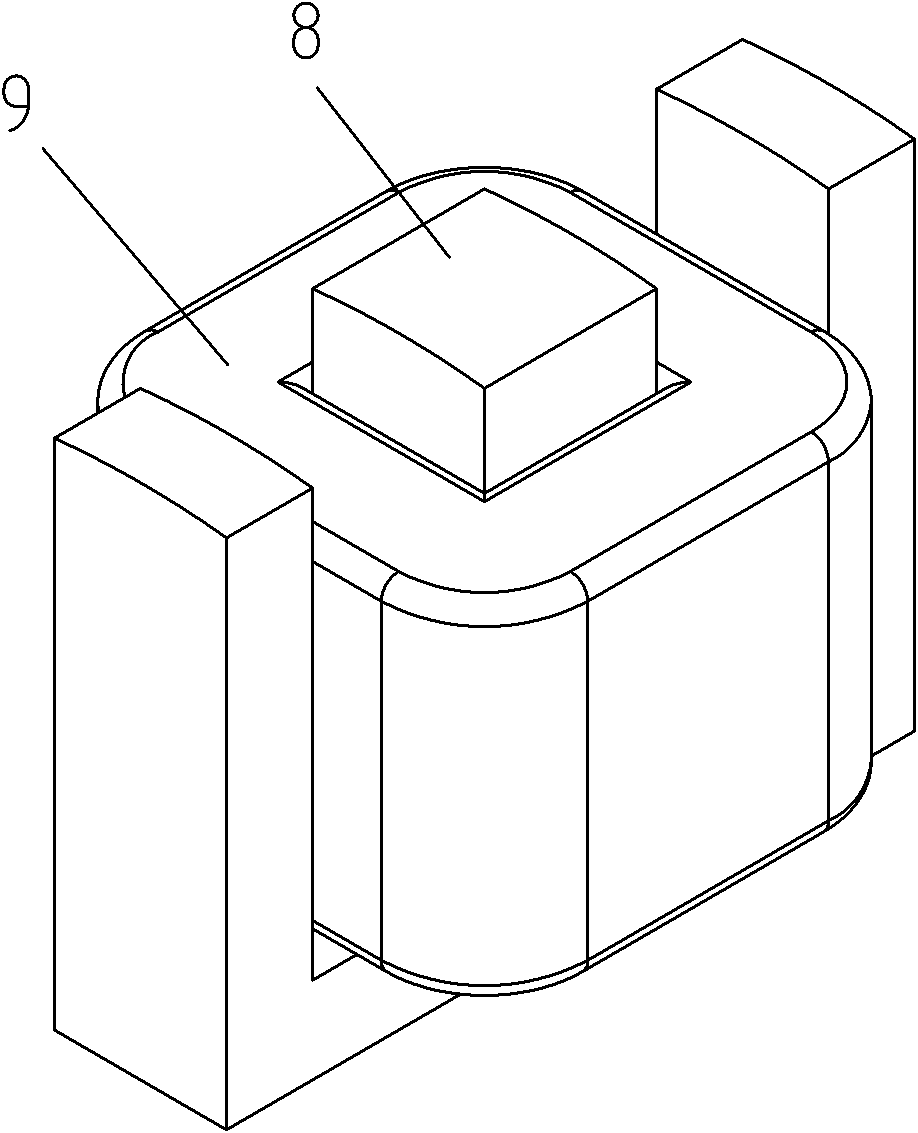

[0035] The electromagnetic induction heating pressure roller provided in this embodiment has a structure such as Figure 1 to Figure 4 As shown: it includes a set of rotating device composed of rotating shaft 1 and moving roller 20, and a set of fixing device composed of magnetizer 8, excitation coil 9, sleeve 10 and fixed shaft 14.

[0036] Three bearings are installed on the rotating shaft 1, wherein: there are two bearings on the right side of the installation position of the key 6, namely the first bearing 15 and the third bearing 21, these two bearings are separated by a certain distance, and their outer rings are fixed on the The inner side of fixed axis 14. The outer ring of the first bearing 15 is fixed in the bearing position of the fixed shaft 14 by the end cover 17 . A collar 16 is installed on the right end of the rotating shaft 1 to axially fix the rotating shaft 1 . The left end of the rotating shaft 1 is installed on the left frame 3 through the fourth bearing...

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 lies in that two groups of magnetic conductors and induction coils in adjacent segments are axially staggered on the periphery of the sleeve 10 . Such as Figure 5 As shown, from the left, the first, third, and fifth sections of the magnetizer deflect 22.5°circumferential angles relative to the second, fourth, and sixth sections of the magnetizer. This method of segmented staggered arrangement can further reduce the The excitation coupling is beneficial to improve the temperature control accuracy of the working surface of each section of the heating roller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com