Liquid continuous impact flow heterogeneous reaction and aerobic fermentation technical equipment

A multiphase reaction, aerobic fermentation technology, applied in bioreactor/fermenter combinations, specific-purpose bioreactors/fermenters, chemical methods for reacting liquids with gaseous media, etc., can solve the limitations of chemical or Biochemical reaction speed, small gas-liquid contact area, slow transfer speed, etc., to achieve the effect of increasing the average residence time, increasing the transfer speed, and reducing the ventilation flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

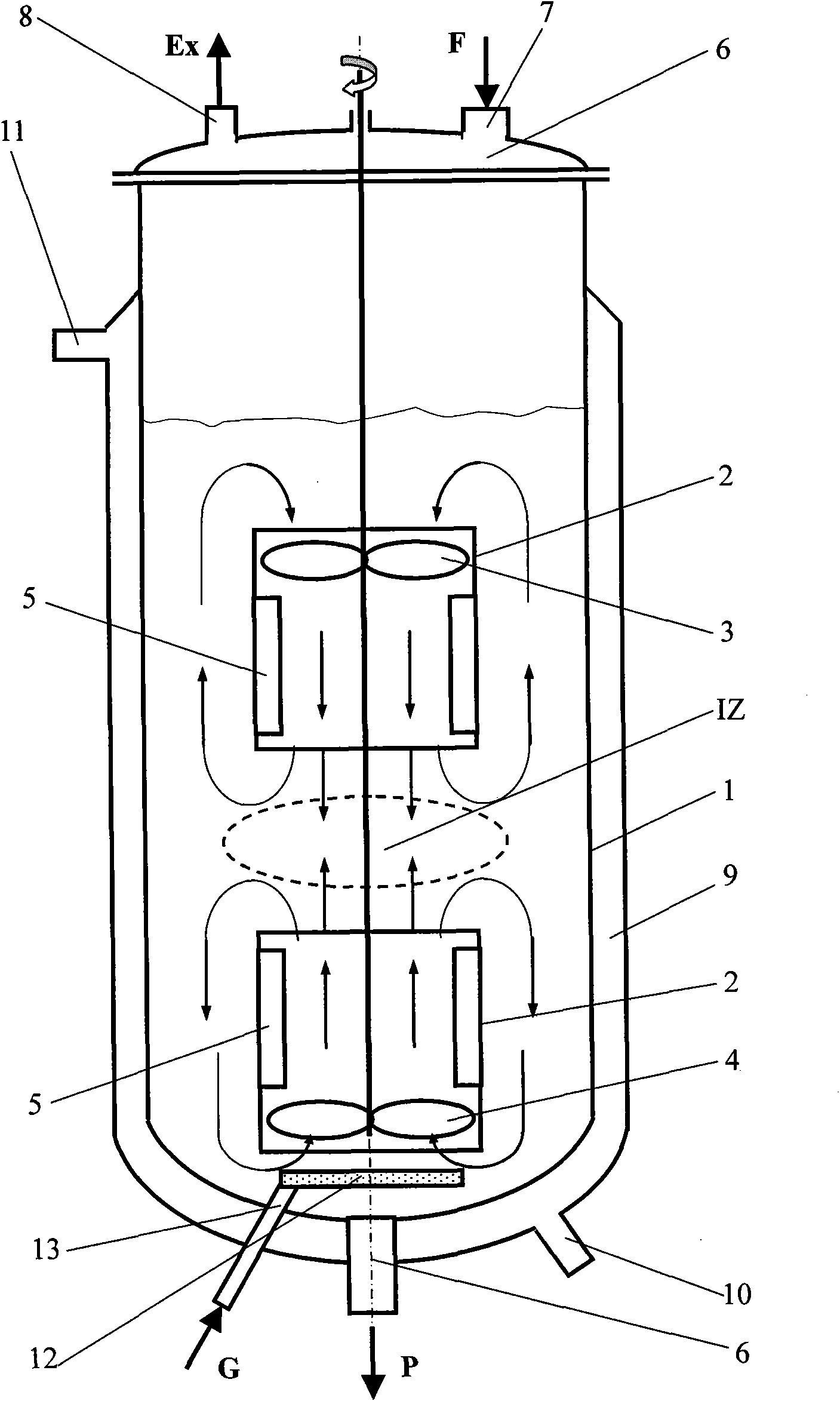

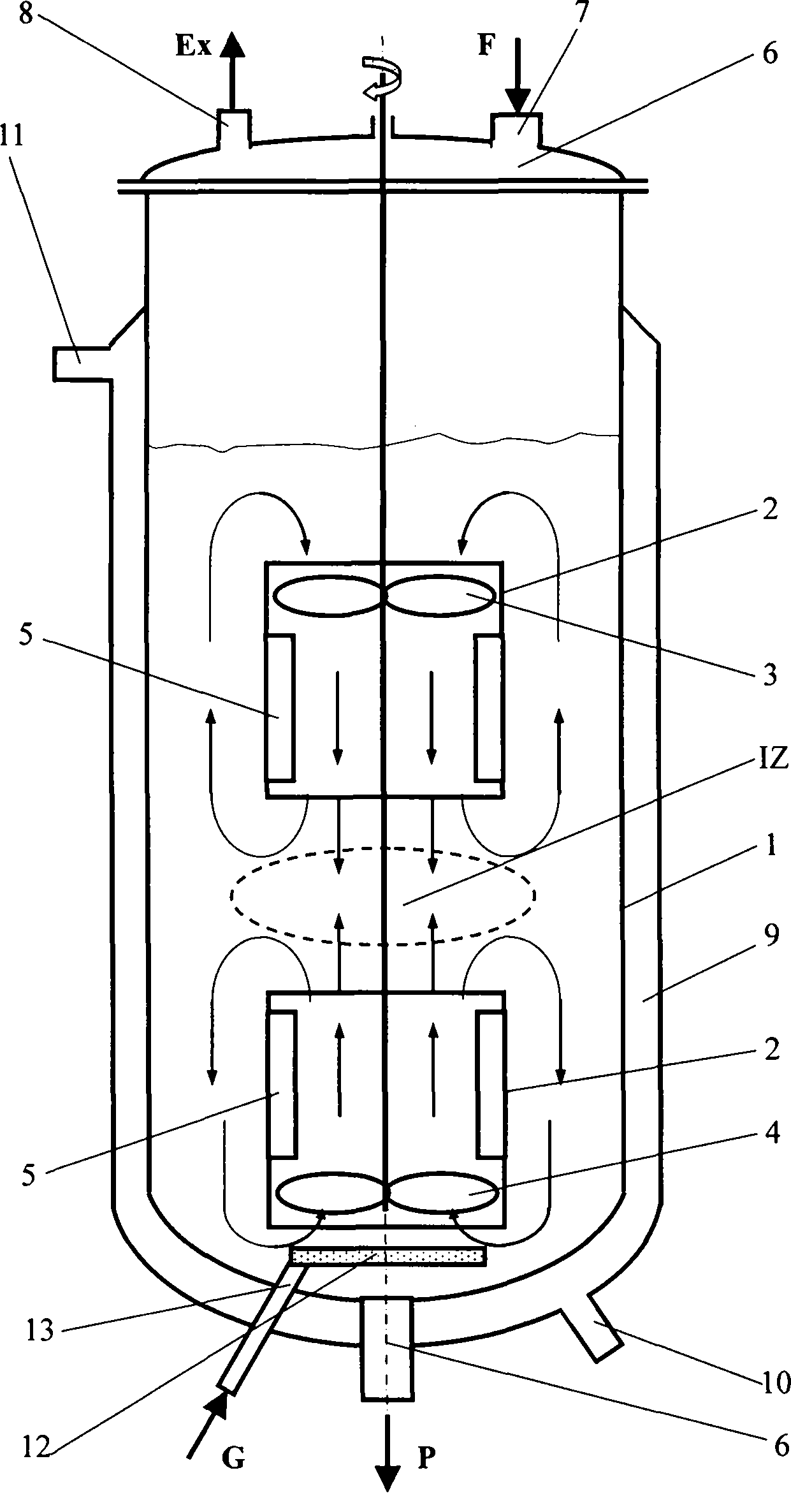

[0013] The invention is used for biomass aerobic fermentation or other gas-liquid phase reactions or gas-liquid-solid three-phase chemical reactions with liquid as the continuous phase, and is usually operated in a batch mode.

[0014] During each batch operation, a quantitative amount of the material to be fermented or other condensed phase reaction materials F is loaded into the reaction vessel 1 at one time, and then the propeller is started. The two propellers 3 and 4 push the fermentation suspension or other reaction materials (process medium) from the upper and lower parts respectively to flow to the middle of the container 1 through the guide tube 2, where they collide with each other, forming a highly turbulent collision around the collision surface District IZ. The heat exchange medium inlet and outlet connection pipes 10 and 11 are opened, and the heat exchange medium exchanges heat with the reaction mixture through the heat exchange jacket 9, so that the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com