Apparatus and method for manufacturing ingot

A technology of ingots and equipment, applied in chemical instruments and methods, self-solidification methods, self-melting liquid extraction methods, etc., can solve the problems of polysilicon ingot quality degradation and other problems, and achieve excellent crystal orientation, particle size increase, inhibition The effect of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

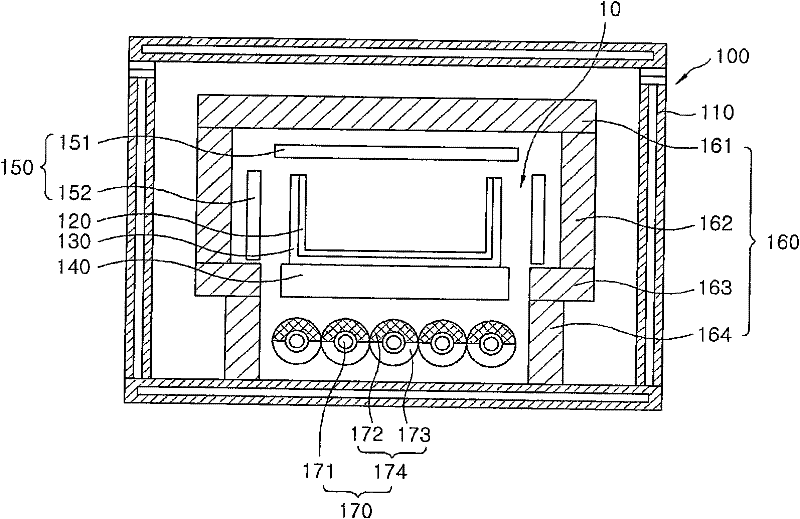

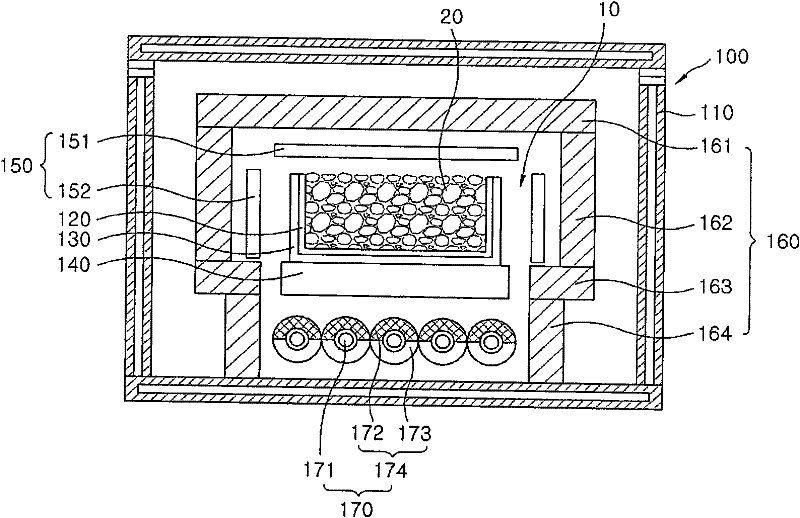

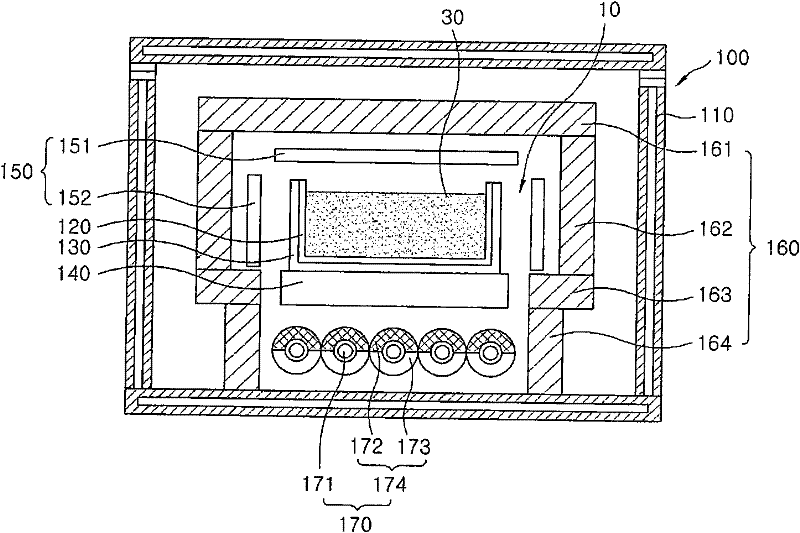

[0045] Hereinafter, specific embodiments will be described in detail with reference to the accompanying drawings. This invention may, however, be embodied in different forms and should not be construed as limited to the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art. In the drawings, the size of each element may be exaggerated for clarity of illustration, and the size of each element may be different from the actual size of each element. Like reference numerals refer to like elements throughout. Polycrystalline silicon ingots were produced according to the following examples, but the present invention is not limited thereto, and thus various ingots can be produced within the scope of the present invention.

[0046] figure 1 is a cross-sectional view illustrating an apparatus for manufacturing a polysilicon ingot according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com