Modularized CO2 laser discharge box

A laser, modular technology, used in lasers, laser parts, laser parts and other directions, can solve the problems of non-adjustment, poor uniformity of glow discharge, low precision, etc., and achieve the effect of ensuring independence, firm and reliable insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

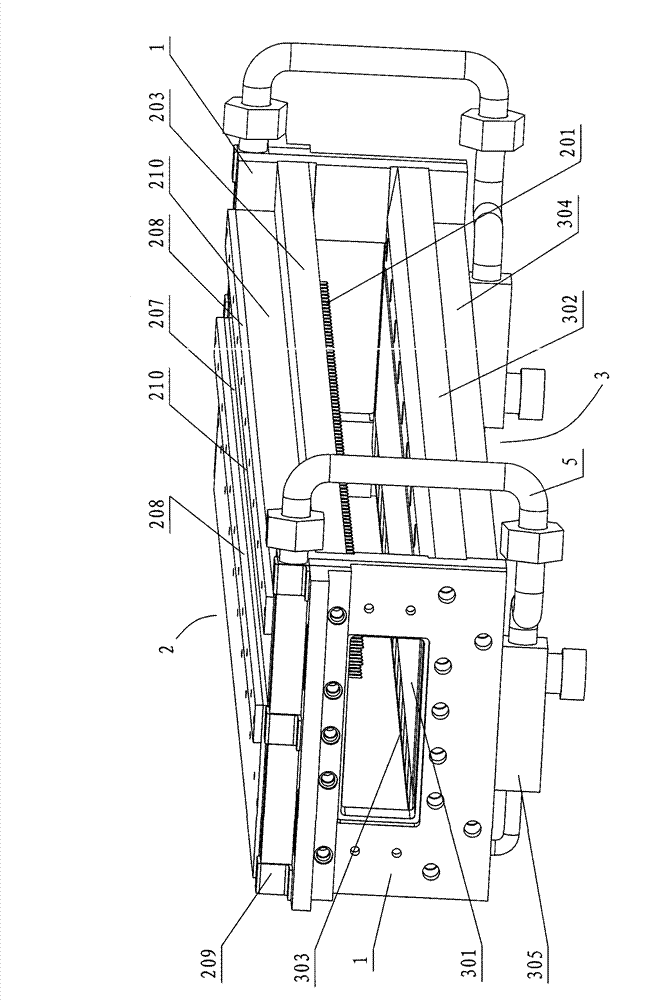

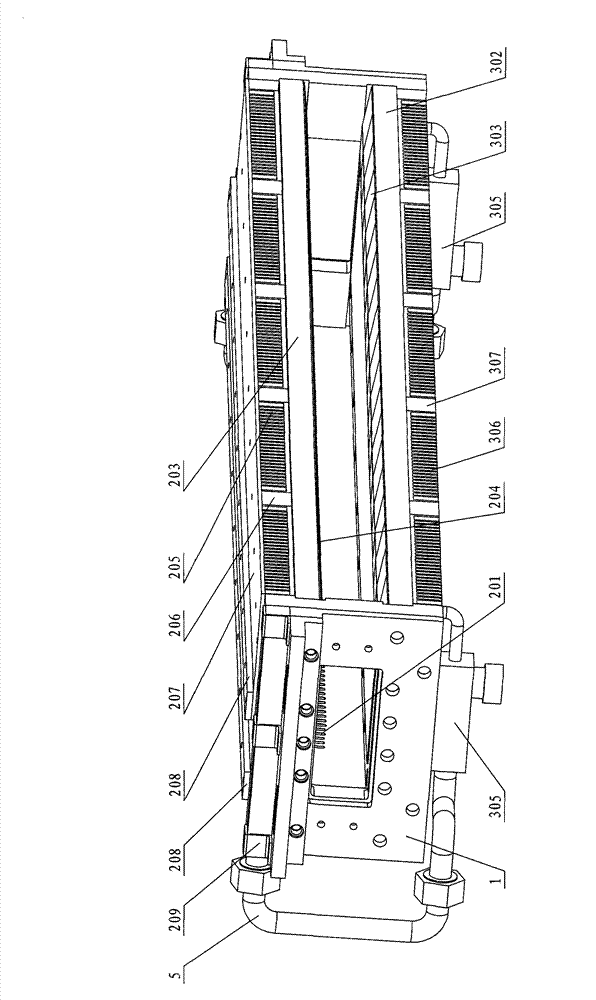

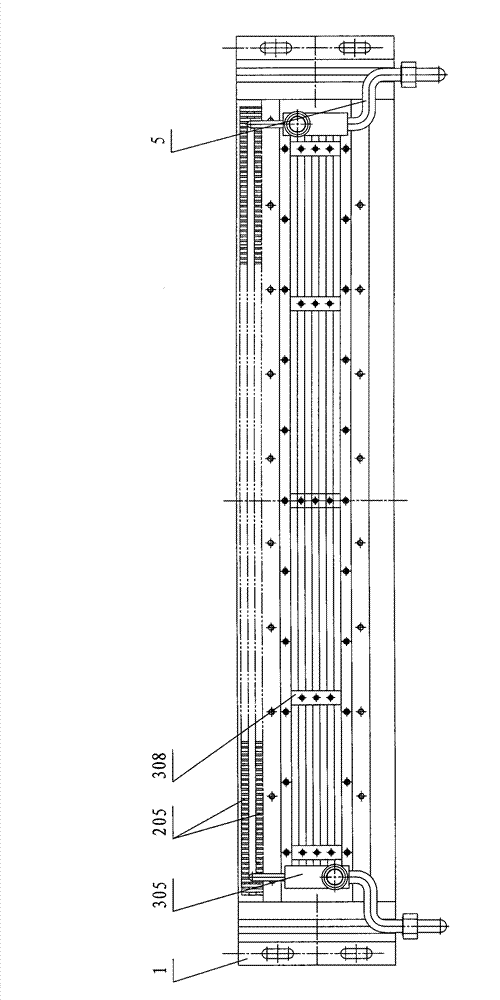

[0037] Such as Figure 1~6 As shown, the present invention includes cathode 2 and anode 3, wherein cathode 2 includes cathode discharge needle 201 and cathode support plate 203, anode includes anode plate 301, anode support plate 302 and cooling water pipe 5, cathode support plate 203 and anode support plate 302 The two ends of the cathode are fastened to the end support plates 1 on both sides by screws respectively, and the gas flow channel 4 in the discharge area is formed between the cathode support plate 203 and the anode support plate 302 . The distance between the cathode support plate 203 and the anode support plate 302 can be 45-50 mm, and the distance in this embodiment is 48 mm, which can be adjusted by adjusting the thread height on the end support plate 1 .

[0038] The opposite side of the cathode support plate 203 and the anode support plate 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com