Association analysis method for service performance of high-speed milling cutter

A technology of correlation analysis and high-speed milling, applied in the direction of testing machinability, etc., can solve the problems of factors affecting the service behavior of high-speed milling cutters and the uncertainty of evaluation indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

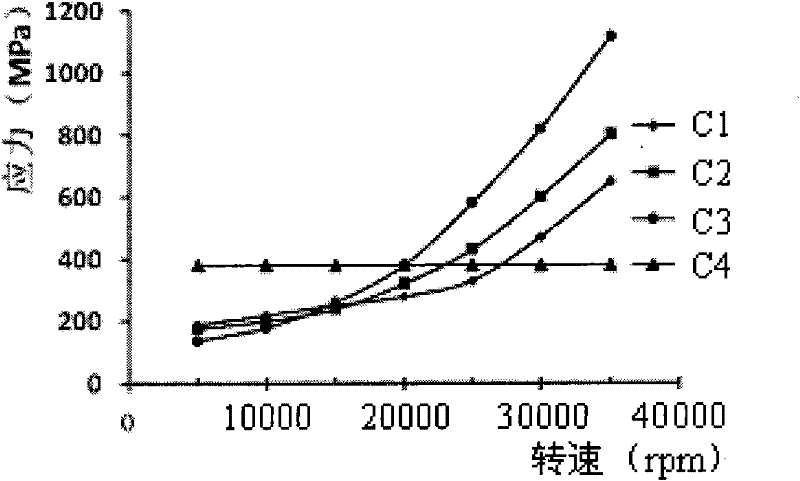

[0019] A high-speed milling cutter service performance correlation analysis method, the method includes the following steps:

[0020] 1. Establish safety criteria for high-speed milling cutters:

[0021] High-speed milling cutter is a series system composed of cutter body, fastening screw, blade and other components. In the process of high-speed milling, when excessive centrifugal force and dynamic cutting force cause structural overload of the milling cutter and cause vibration, the high-speed milling cutter may fail due to deformation, fracture or resonance of the cutter body, blade, screw and other components, and the milling cutter The safety criterion is:

[0022] n≤n f1 / 1.6, n≥n f2 k g or n≤n f2 / k g (1)

[0023] no f1 =min(n 1 , n 2 , n 3 ,...,n i ), n f2 ≈60f gi / k z (2)

[0024] In the formula: n i is the failure speed of the strength of the milling cutter assembly; n f is the resonance failure speed of the milling c...

Embodiment 2

[0063] The milling cutter designed by the method comprises: a tool handle and cutter teeth set on it, the cutter teeth are multi-toothed, the cutter teeth are unevenly distributed, and the diameter of the milling cutter is It is more than 80mm, and the multi-teeth is more than 5 teeth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com