Electro-thermal mulching film heating device

A heating device and electric heating film technology, applied in the field of heating facilities in buildings, can solve problems such as difficult to bury under the cement floor, material aging, electromagnetic radiation, etc., to reduce floating dust and dry air, avoid waste, and uniform temperature field Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

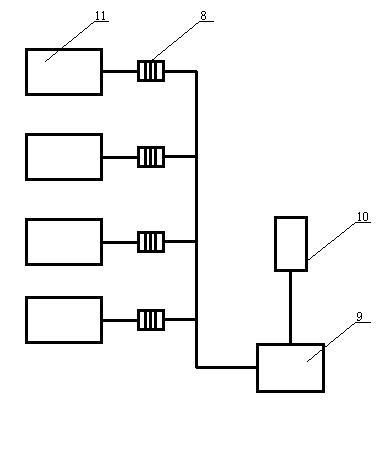

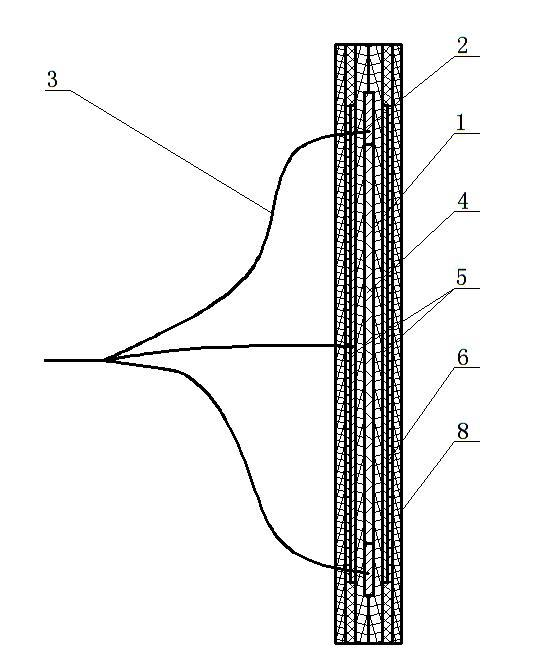

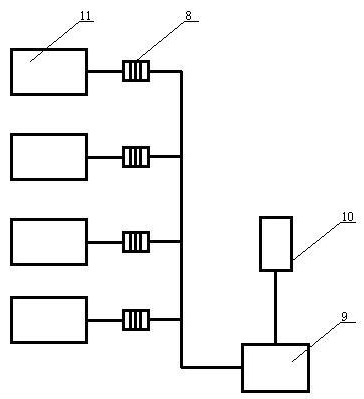

[0017] The electric heating film heating device comprises: a group of electric heating diaphragms 11 connected by plug-in waterproof joints 7, the electric heating diaphragms are connected to a thermostat 9, the thermostat is connected to a power supply 10, the The electrothermal diaphragm is an electrothermal diaphragm that prevents leakage, electricity and radiation. The electrothermal diaphragm is bonded by two or more than two layers of polyester film 1. The copper conductive electrodes 2 connected by paste, the conductive electrodes on both sides are respectively connected to the wires 3, the conductive electrodes on both sides are connected to the uniform printing ink conductive strips 4, and the two sides of the polyester film are There are conductive aluminum foil strips 5 on the sides respectively, the conductive aluminum foil strips are connected to the zero-line electrode, a thermostat is installed on the wire, and the thermostat has a connection line connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com