Steel tube concrete column-double-layer steel plate combined shear wall and construction method thereof

A technology of steel tube concrete columns and combined shear walls, applied in walls, building components, buildings, etc., can solve the problems of poor deformation capacity of concrete walls, affect the seismic performance of high-rise buildings, restrict the flexibility of building layout, etc., and achieve the reduction of formwork The effect of engineering quantity, reduction of foundation cost, improvement of bearing capacity and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

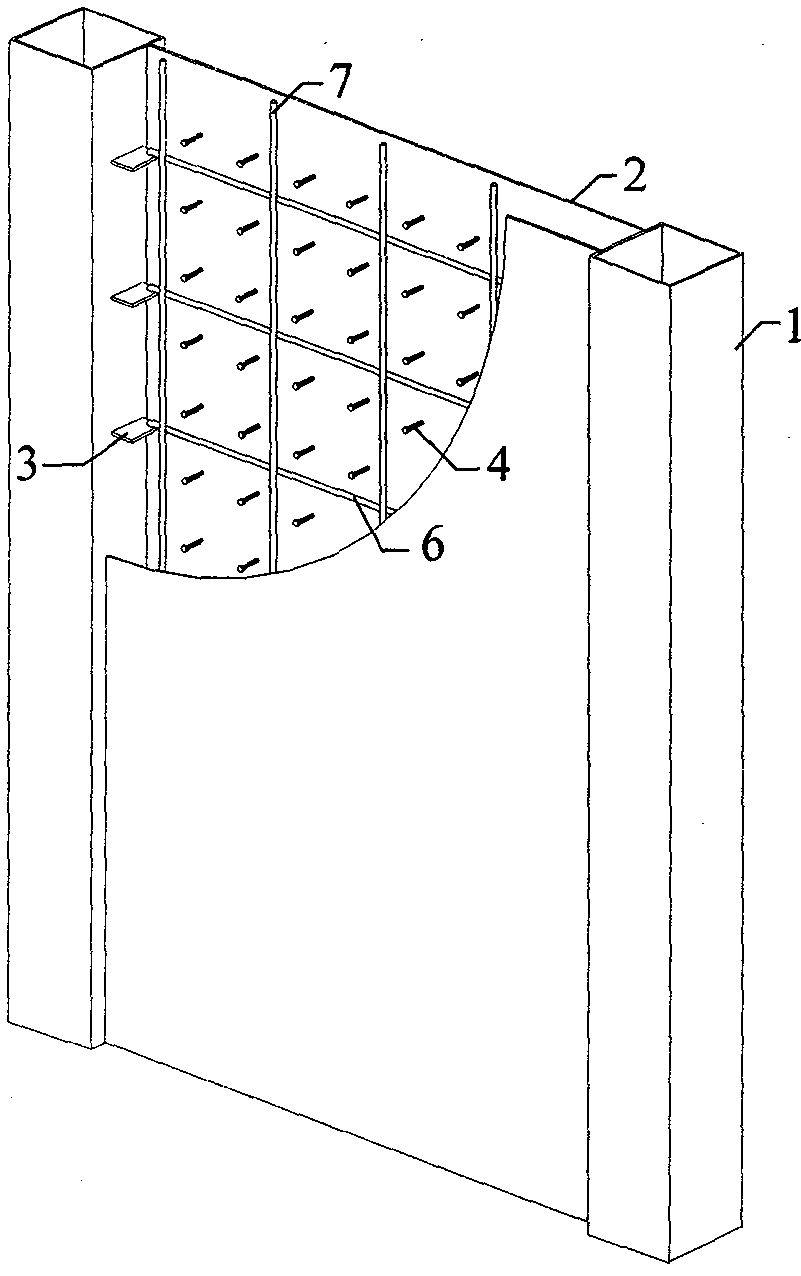

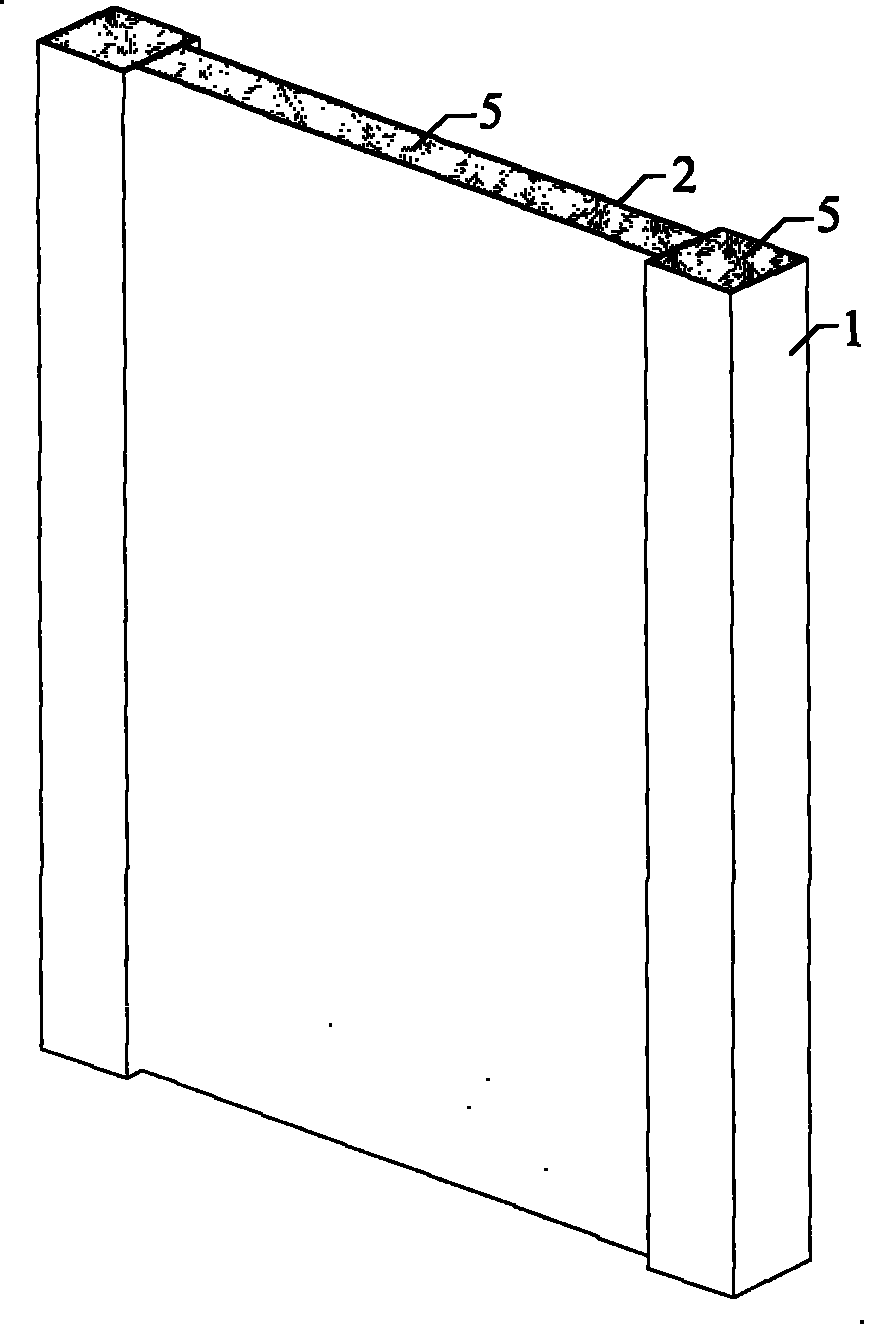

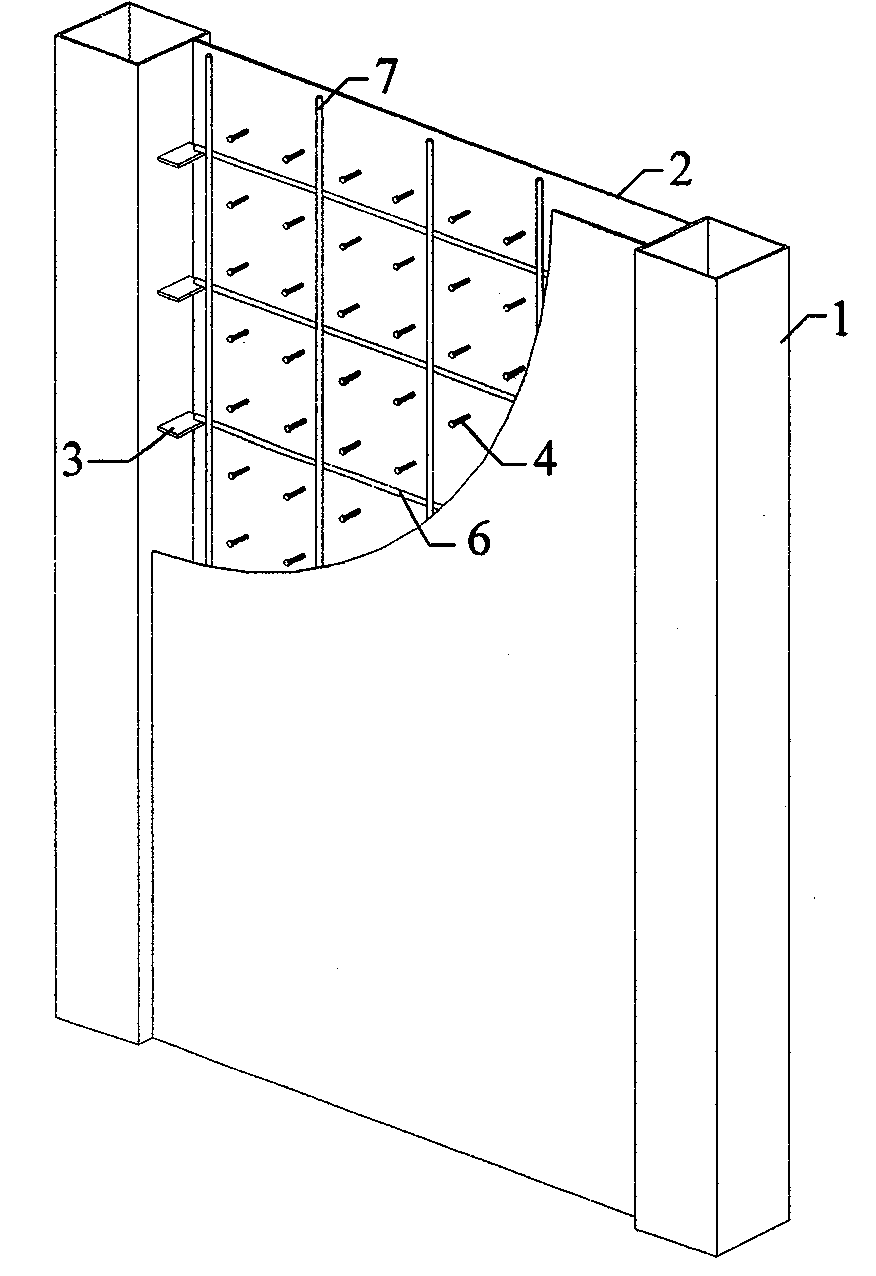

[0022] The specific implementation method of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] like Figure 1 ~ Figure 2 As shown, the shear wall includes two steel pipes 1, two steel plates 2, distributed steel bars, connection keys 3, studs 4 and concrete 5; the opposite sides of the two steel pipes are arranged with connection keys 3 vertically , the two ends of the horizontally distributed reinforcing bars in the distributed reinforcing bars are respectively connected to the corresponding connecting keys 3 on the two steel pipes; the two steel plates 2 are welded with studs 4 on the opposite surfaces; the described Both ends of the two steel plates 2 are connected to the steel pipe 1; concrete 5 is poured in the two steel pipes 1 and in the plane enclosed space surrounded by the two steel plates 2 and the two steel pipes 1.

[0024] The steel pipe 1 is circular, square or rectangular. The connections between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com