Coated and perfumed environment-friendly lining paper of cigarette packet

A technology of coating flavoring and lining paper, which is applied in papermaking, coating, paper coating, etc., to achieve simple production process, maximize utilization, and enhance the effect of cigarette aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

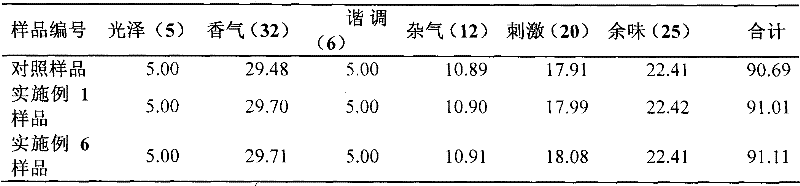

Examples

Embodiment 1

[0015] Weigh 5.5kg of tobacco extract, 28.0kg of water, 0.4kg of thickener starch, 0.03kg of pH regulator potassium citrate / sodium, and 0.01kg of antioxidant vitamin C. Pour water into the container holding the tobacco extract, reserve part of the water, stir until the tobacco extract is completely dissolved, add the thickener, and mix evenly. Dissolve the pH adjuster and antioxidant in the reserved water respectively, then add them into the thickened liquid material, and stir evenly to obtain the coating liquid. Apply the paint on the inner liner paper base by using the existing knife coating or roll coating process, and the coating amount is controlled at 2-20g / m 2 . Then adopt the existing technology to carry out drying and surface treatment, and produce the finished inner lining paper for cigarettes after the processes such as edge trimming and slitting.

Embodiment 2

[0017] Weigh 2.5kg of tobacco extract, 22.0kg of water, 0.05kg of guar gum, 0.03kg of potassium / sodium tartrate, and 0.01kg of rosmarinic acid. Prepare coating solution method and coating method with embodiment 1.

Embodiment 3

[0019] Weigh 2.5kg of tobacco extract, 39.5kg of water, 2.5kg of ethanol, 0.5kg of thickener PVA, 0.05kg of pH regulator potassium / sodium malate, and 0.04kg of antioxidant apple polyphenols. Mix the ethanol and water, reserve a small amount of the mixed solution, pour the rest into the container containing the tobacco extract, stir while stirring, add the thickener after completely dissolving, and mix evenly. The pH adjuster and the antioxidant are dissolved in the reserved mixed solution respectively, and then added to the thickened material liquid, and stirred evenly to obtain the coating liquid. Apply the coating on the inner liner paper base by knife coating or roll coating process, and the coating amount is controlled at 2-20g / m 2 . Then adopt the existing technology to carry out drying and surface treatment, and produce the finished inner lining paper for cigarettes after the processes such as edge trimming and slitting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com