Electrode device of electrochemical cleaning salt-bath furnace

A technology of electrode device and salt bath furnace, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of poor cleaning effect of electrochemical cleaning salt bath furnace, uneven charge distribution, short service life of electrodes, etc., and achieve uniform charge distribution Good, uniform charge distribution, and long service life of the electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by way of implementation and accompanying drawings:

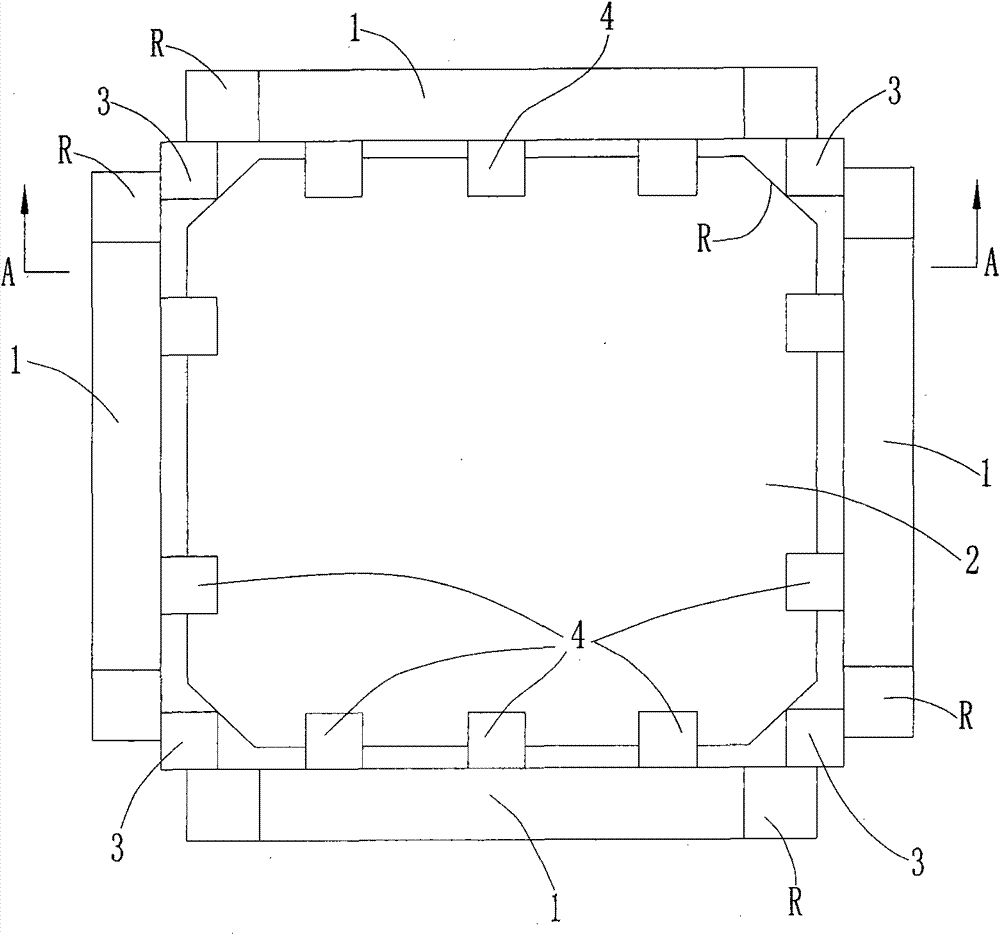

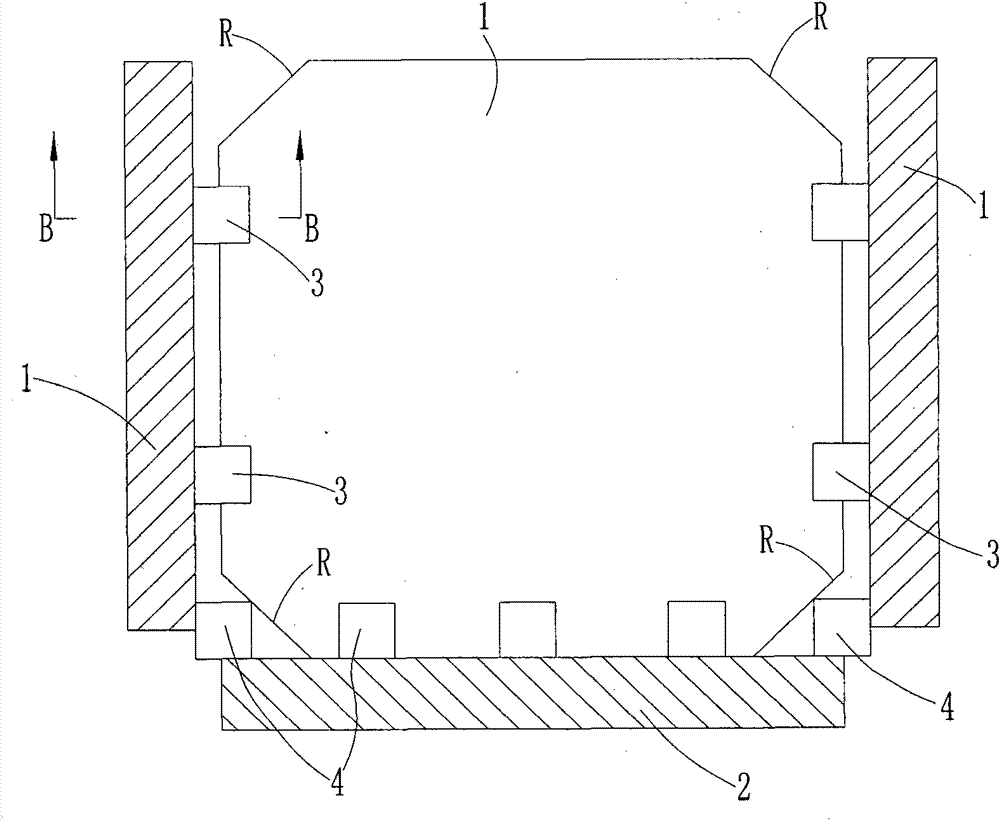

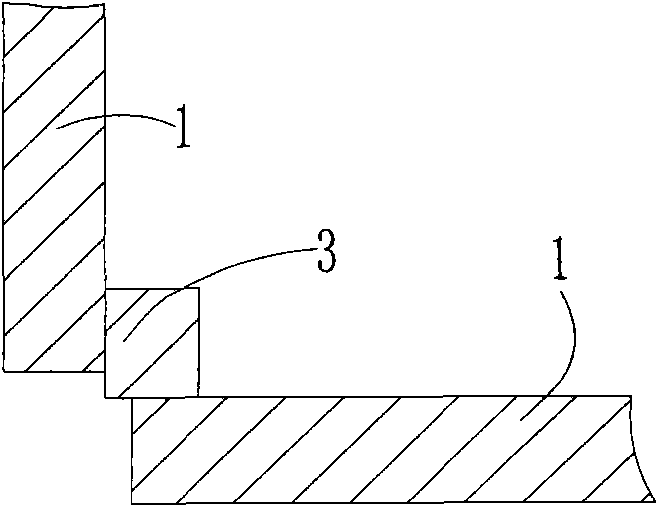

[0015] see Figure 1-Figure 3 : The device comprises a square cylinder with an open upper end surrounded by four conductive square side plates 1 and a square bottom plate 2, and two adjacent side plates 1 are connected by two vertically arranged first conductive plates spaced apart from each other. Blocks 3 are connected so that there is a gap between adjacent two side plates 1, each side plate 1 and bottom plate 2 are connected by two or three second conductive connecting blocks 4 arranged horizontally and spaced from each other, so that each There is a gap between the side plate 1 and the bottom plate 2 . The four corners of the bottom plate 2 and each side plate 1 have a 45-degree chamfer R, and the bottom plate 2 and each side plate 1 are made of Q235 steel plates with a thickness of 12-20mm. The distance between two adjacent first conductive conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com