Direct biomass hydroliquefaction process comprising two ebullated bed hydroconversion steps

A technology of hydrogenation conversion and hydrogenation liquefaction, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, biofuels, etc., can solve problems such as operational difficulties, and achieve operability improvement and optimization Preparation, life-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

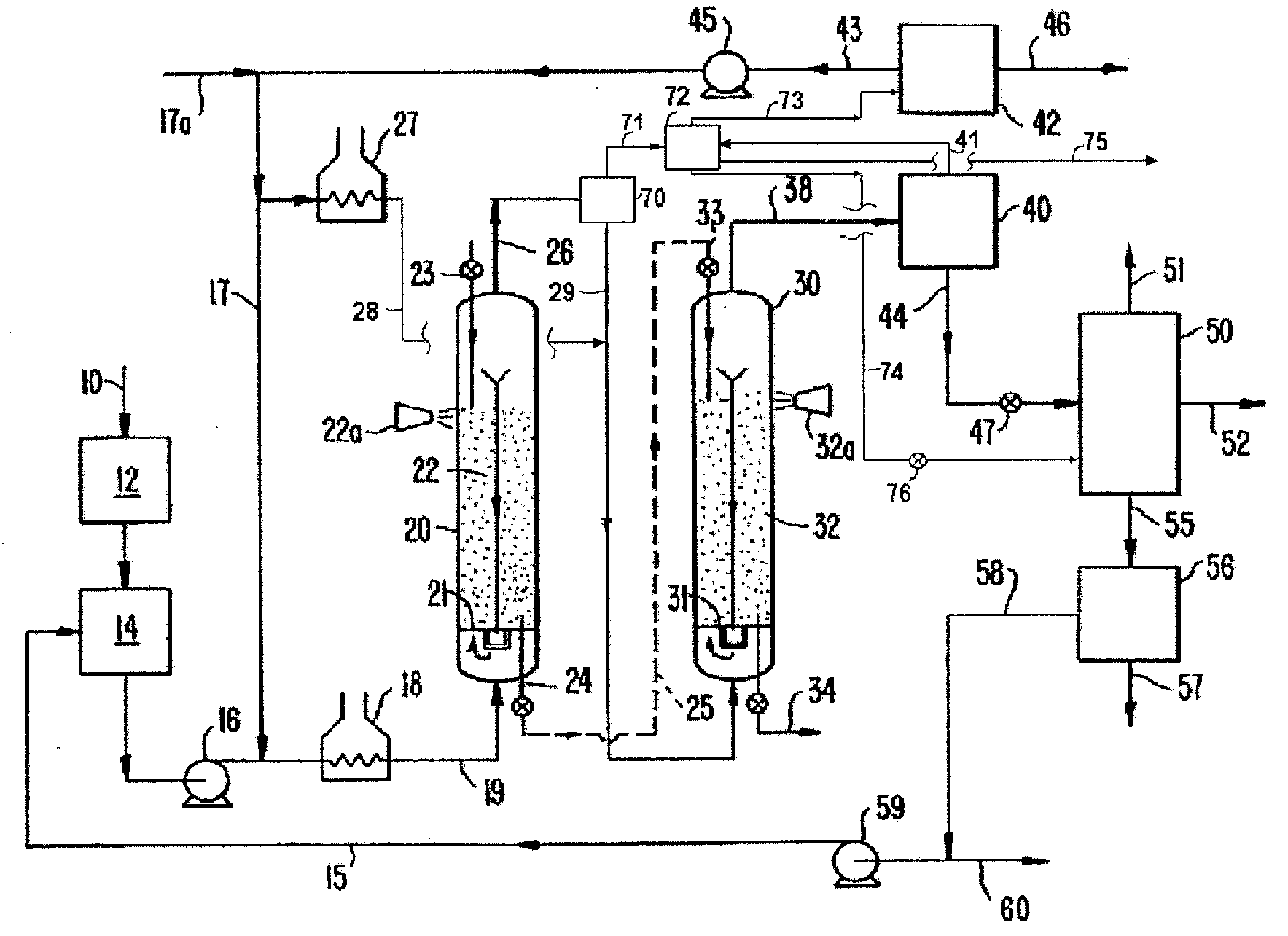

[0045] The present invention relates to a process for the direct hydroliquefaction of biomass, alone or in combination, to produce a fuel base. More particularly, the present invention relates to a process comprising two consecutive hydroconversion steps using ebullating bed technology at high hydrogen pressure.

[0046] Biomass feed

[0047] The biomass feed may be selected from algae, lignocellulosic biomass and / or one or more components of lignocellulosic biomass selected from the group comprising cellulose, hemicellulose and / or lignin .

[0048] "Lignocellulosic biomass" means a feedstock rich in cellulose and / or hemicellulose and / or lignin. Only one of the components of the lignocellulosic biomass can be extracted for hydroliquefaction. This extract or other remainders may also constitute feedstock, especially lignin, which may be used in the present invention.

[0049] The lignocellulosic feedstock may consist of wood or plant waste. Other non-limiting examples of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com