Punching die for plastic film or polyester carbonate film product

A carbonated polyester and product technology, applied in the field of punching molds, can solve problems such as affecting product quality, leaking perforation, and poor non-punching of dirty products, and achieve the effects of shortening operation time, facilitating separation, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

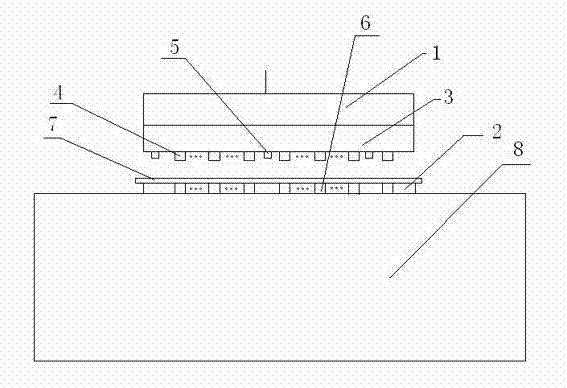

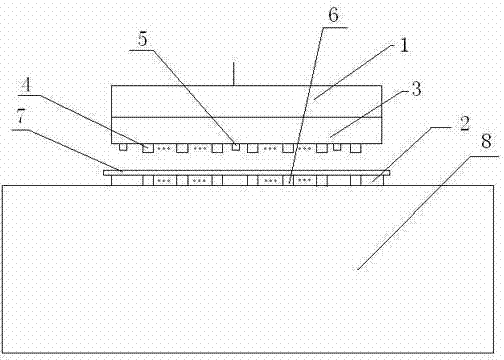

[0015] like figure 1 Shown: a punching die for plastic film or polyester carbonate film, including an upper die 1 and a lower die 2, the upper die 1 and the lower die 2 are set correspondingly, wherein the surface of the upper die 1 is a steel plate 3, and the steel plate 3 is mounted on There are a plurality of punching blocks 4, the shape of the punching blocks 4 is consistent with the hole pattern of the plastic thin film or polyester carbonate film product, and its arrangement is consistent with the arrangement of the hole pattern of the plastic thin film or polyester carbonate film product, The lower mold 2 is then fixed on the machine platform 8, and its surface is provided with a waste discharge hole 6 which is consistent with the shape of the punch block 4 and correspondingly arranged. In addition, a steel knife 5 for dividing adjacent plastic film or polyester carbonate film products is also installed on the steel plate 3 , wherein the height of the steel knife 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com