Built-in cooling and filtering device

A filter device, built-in technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as increased maintenance costs, increased cutting oil temperature, and fragile control panels, and achieve direct savings Cost, oil temperature control precise, easy to detect the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

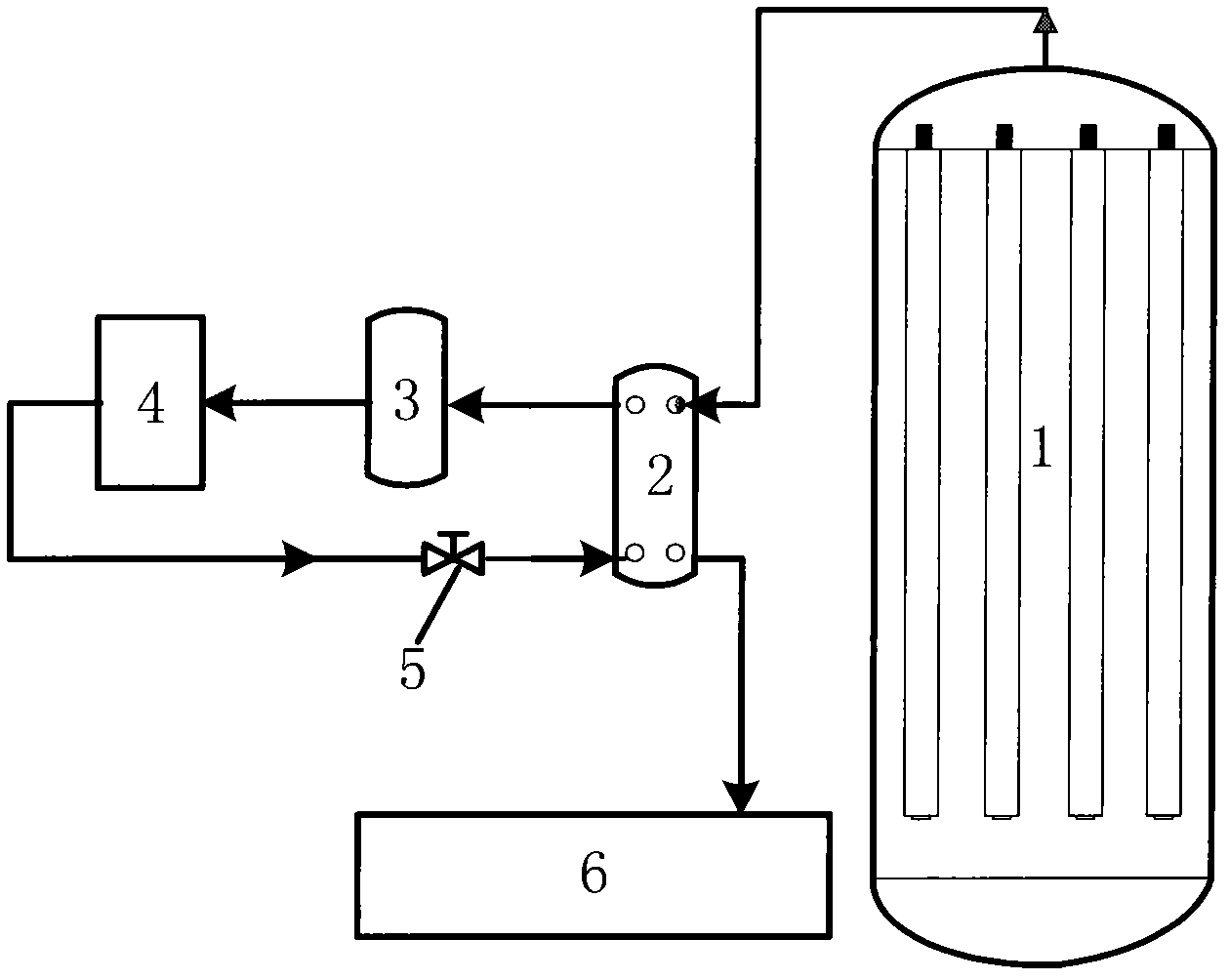

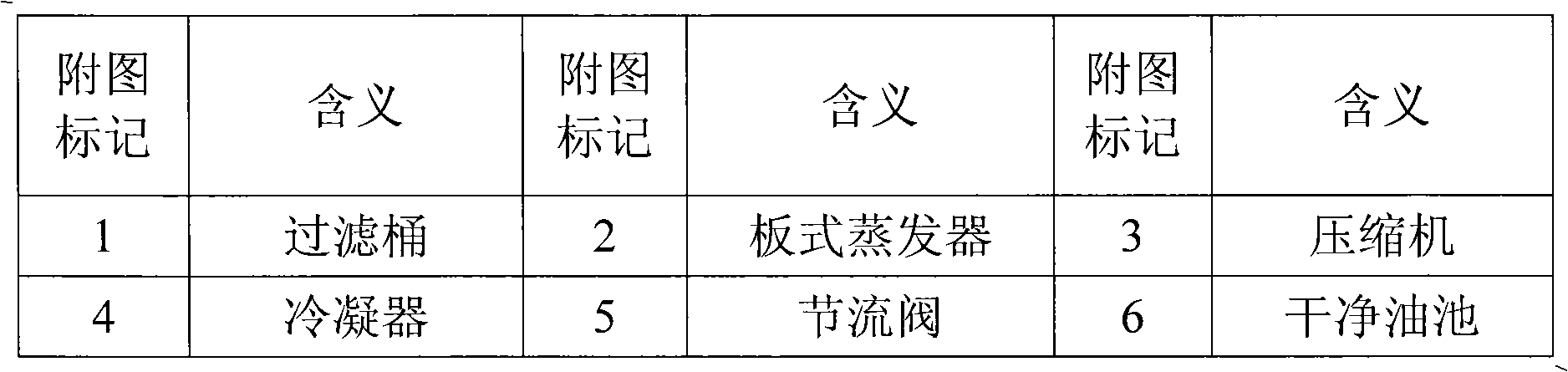

[0016] Such as figure 1 As shown, the built-in cooling and filtering device includes a filter barrel 1, a plate evaporator 2 and a clean oil pool 6. The oil outlet on the upper part of the filter barrel 1 is connected to the oil inlet of the plate evaporator 2 through an oil pipe, and the outlet of the plate evaporator 2 The oil port is connected to the clean oil pool 6 through the oil pipe; the refrigerant outlet of the plate evaporator 2 is connected to the inlet of the compressor 3 through the refrigerant pipeline, and the outlet of the compressor 3 is connected to the refrigerant inlet of the condenser 4 through the refrigerant pipeline, and the refrigerant of the condenser 4 The outlet is connected to the inlet of the throttle valve 5 through a refrigerant pipeline, and the outlet of the throttle valve 5 is connected to the refrigerant inlet of the plate evaporator 5 through a refrigerant pipeline. Among them, the refrigerant pipeline adopts copper pipe.

[0017] In specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com