Iron-based powder alloy and argon arc surfacing technology utilizing same

An iron-based powder and alloy technology, applied in arc welding equipment, welding medium, welding equipment and other directions, can solve the problems of decreased surfacing welding quality, easy oxidation of alloy powder, difficult engineering application, etc., to reduce labor intensity and reduce equipment investment. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of iron base powder alloy, its main component is: the mol ratio of its component is: Fe-V: Fe-B: C=1.0: 0.05: 1.0; Wherein, Fe-V composition is wt% to be 65% V, 2.0% Al, 0.5% Si, 0.01% C, the rest of Fe; the Fe-B composition is 25% B, 0.5% Al, 1.0% Si, 0.01% C, 0.5% Mn, and the rest of Fe by weight.

[0025] The above-mentioned iron-based powder alloy is applied to the argon arc surfacing technology, and the specific steps are as follows:

[0026] (1), configure Fe-V, Fe-B, graphite-iron-based powder alloy, the composition mol ratio is: Fe-V: Fe-B: C = 1.0: 0.05: 1.0;

[0027] (2), mix the powder evenly with water glass, and press it on the mould;

[0028] (3), dry naturally for 5 hours, take out the thin slice and dry it at 60°C for 2 hours at low temperature;

[0029] (4), select Q235 (low carbon steel), Q345 (low alloy steel) materials for surfacing;

[0030] (5), natural cooling after welding.

Embodiment 2

[0032] A kind of iron base powder alloy, its main component is: the mol ratio of its component is: Fe-V: Fe-B: C=1.0: 0.08: 0.5; Wherein, Fe-V composition is wt% is 75% V, 1.0% Al, 1.0% Si, 0.05% C, Fe balance; Fe-B composition is 20% B, 1.0% Al, 0.5% Si, 0.1% C, 0.3% Mn, Fe balance.

[0033] The above-mentioned iron-based powder alloy is applied to the argon arc surfacing technology, and the specific steps are as follows:

[0034] (1), configure Fe-V, Fe-B, graphite-iron-based powder alloy, the composition mol ratio is: Fe-V: Fe-B: C = 1.0: 0.08: 0.5;

[0035] (2), mix the powder evenly with water glass, and press it on the mould;

[0036](3), dry naturally for 5 hours, take out the thin slice and dry it at a low temperature of 120°C for 1.5 hours;

[0037] (4), select Q235 (low carbon steel), Q345 (low alloy steel) materials for surfacing;

[0038] (5), natural cooling after welding.

Embodiment 3

[0040] A kind of iron base powder alloy, its main component is: the mol ratio of its component is: Fe-V: Fe-B: C=1.0: 0.1: 0.8; Wherein, Fe-V composition is wt% to be 70% V, 1.5% Al, 0.2% Si, 0.1% C, Fe balance; Fe-B composition is 22.5% B, 1.5% Al, 0.1% Si, 0.05% C, 0.1% Mn, Fe balance.

[0041] The above-mentioned iron-based powder alloy is applied to the argon arc surfacing technology, and the specific steps are as follows:

[0042] (1), configure Fe-V, Fe-B, graphite-iron-based powder alloy, the composition mol ratio is: Fe-V: Fe-B: C = 1.0: 0.1: 0.8;

[0043] (2), mix the powder evenly with water glass, and press it on the mould;

[0044] (3) Dry naturally for 5 hours, take out the thin slice and dry it at 90°C for 1 hour at low temperature;

[0045] (4), select Q235 (low carbon steel), Q345 (low alloy steel) materials for surfacing;

[0046] (5), natural cooling after welding.

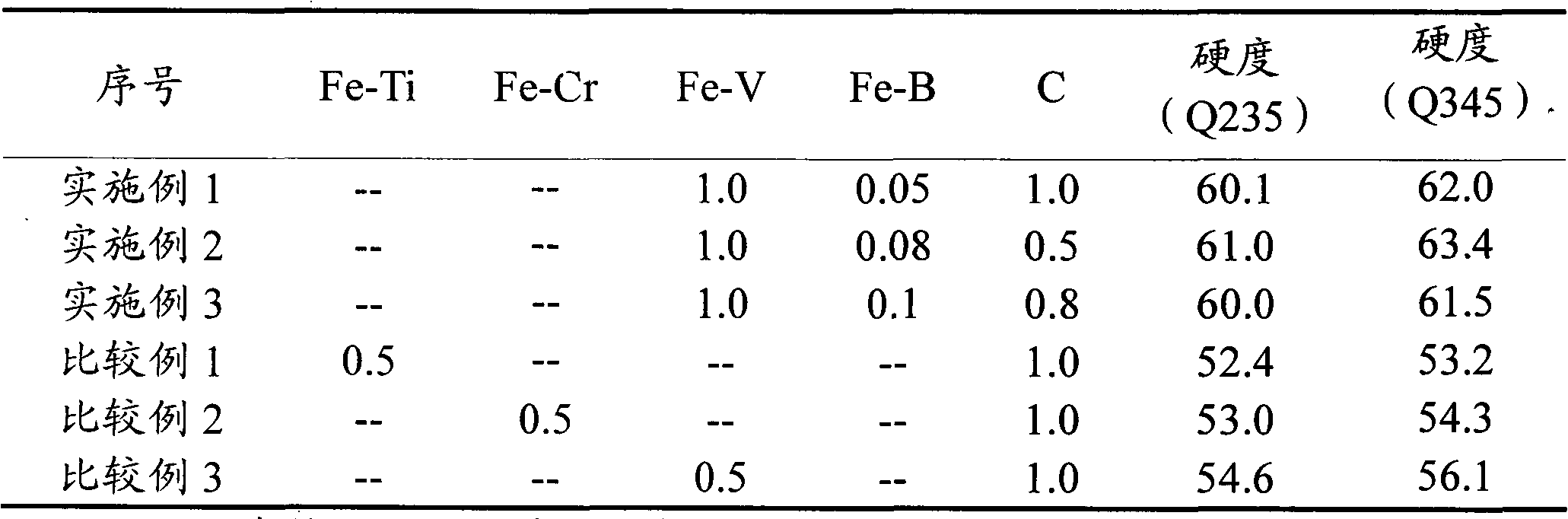

[0047] The average surface hardness of the argon arc surfacing welding layer measured by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com