Light metal and bare steel plate spot-welding method based on bulk forming solder

A metal plate and light metal technology, applied in the field of optimizing dissimilar metal spot welding, can solve the problems of joint deformation, bare steel plate cannot be connected with light metal materials to obtain good joints, reduce vehicle body design and manufacturing costs, achieve less welding defects, and be easy to promote Application, effect of improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

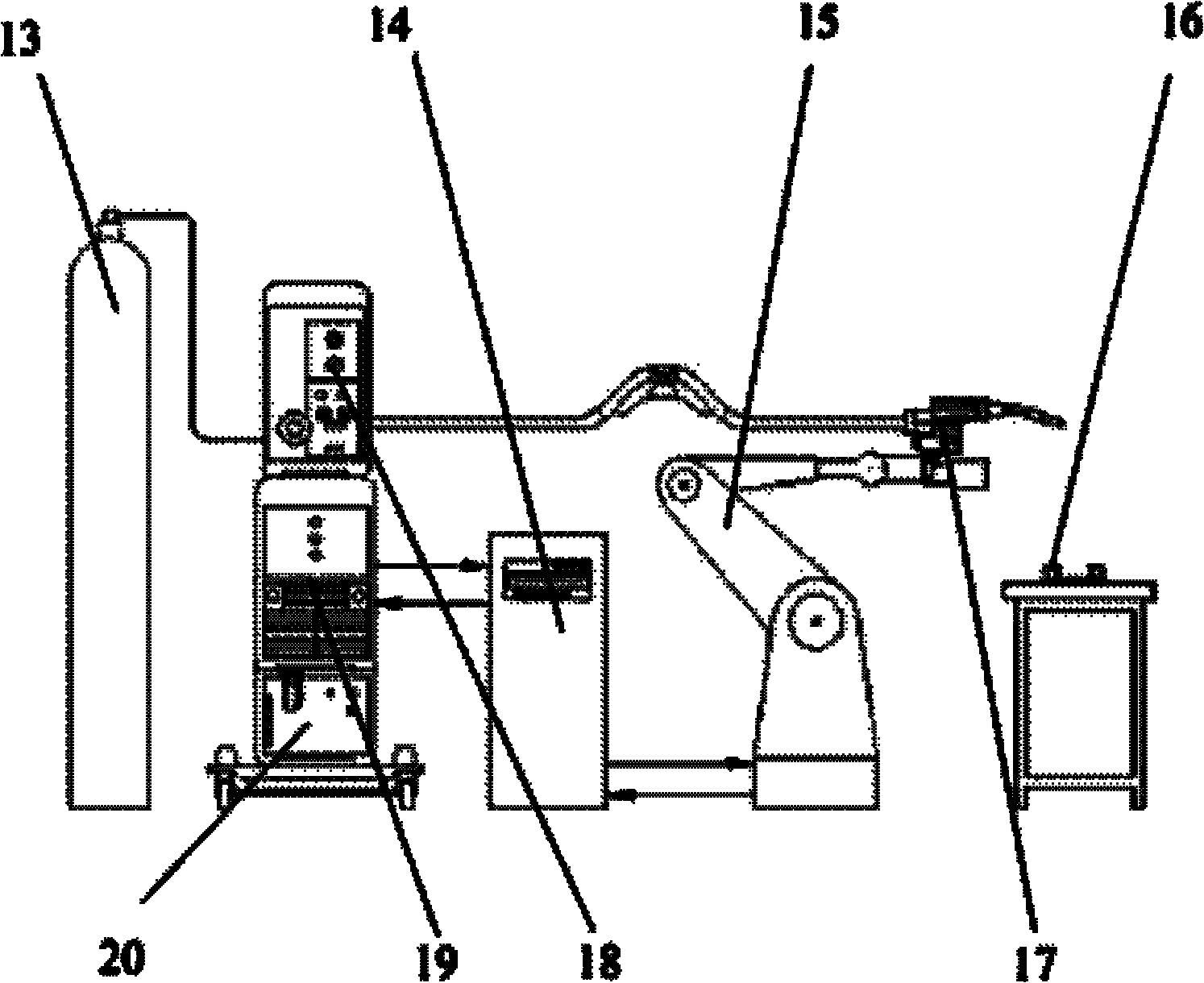

[0032] Such as figure 1 , 2 , 3, and 4, this embodiment includes a solder shaping and embedding device and an arc welding system.

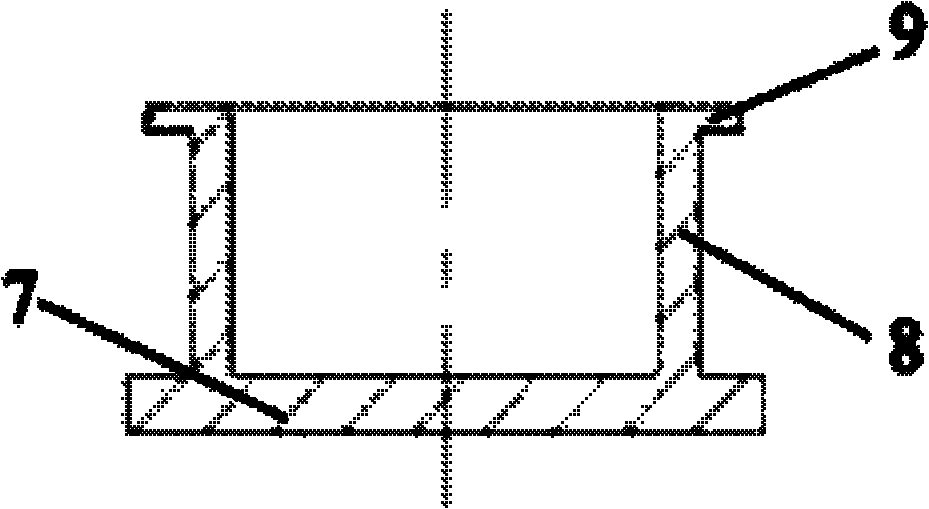

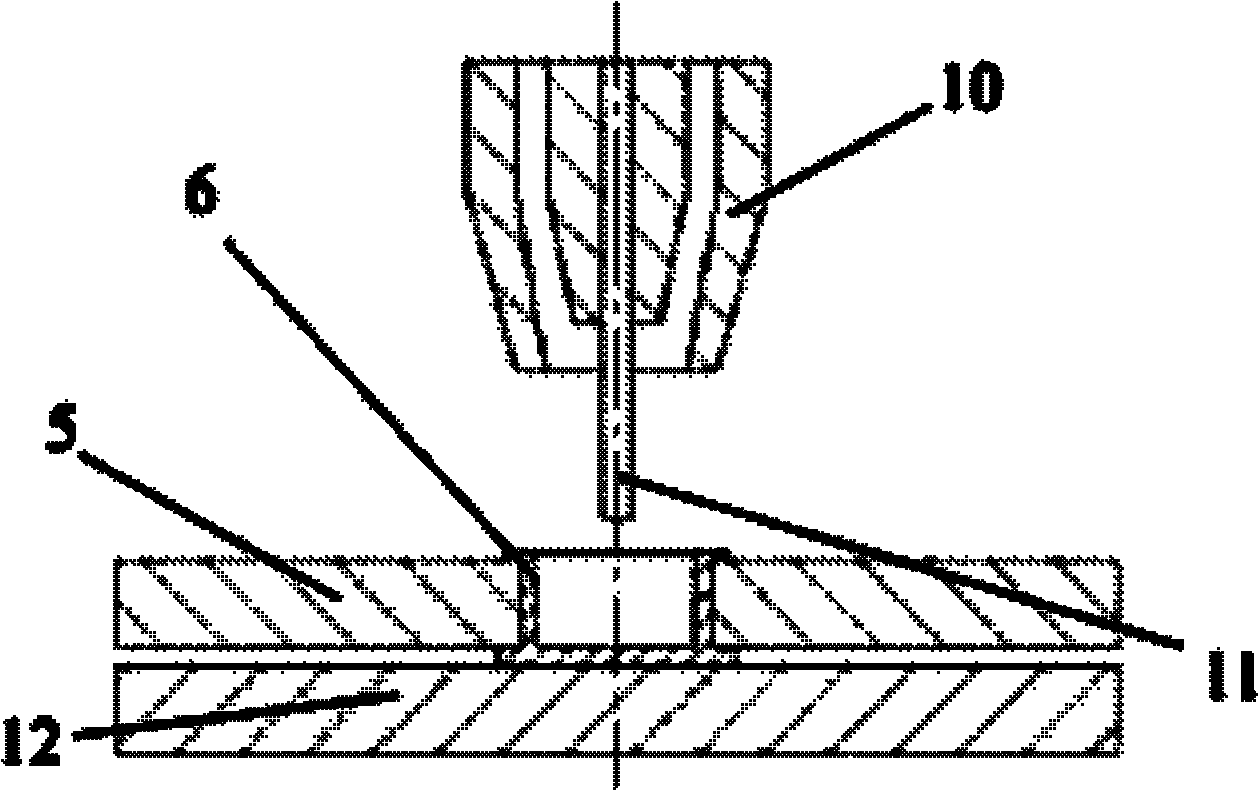

[0033] The solder shaping and embedding device includes: a punch 1 , an upper die 2 , a blank holder 3 , and a lower die 4 . Among them: the punch 1 is fixedly connected with the upper die 2 and sleeved in the blank holder 3, the perforated light metal plate 5 and the solder 6 are placed on the lower die 4, the punch 1, the upper die 2, the blank holder 3 and the The lower mold 4 is set coaxially.

[0034] The punch 1 provides downward pressure during the extruding process of the brazing filler metal 6 , and is threaded inside so as to be connected with the upper die 2 .

[0035] The end of the upper die 2 is fixedly connected to the punch 1 through threads, and in the extrusion molding process of the solder 6, forms a cavity with the lower die 4 and the perforated light metal plate 5, so that the extruded solder 6 Fill the inside of the cavit...

Embodiment 2

[0053] The upper light metal plate 5 of this embodiment is aluminum alloy AA6061-T6, the lower bare steel plate 12 is high-strength steel DP780, the thickness of the plate is matched: 1mm+2mm, the hole diameter is 6.5mm, the center distance between the holes is 20mm, aluminum The alloy plate 5 is mechanically polished to remove the oxide layer on the surface, and acetone reagent is used to remove the oil stain on the surface of the metal plate.

[0054] Process parameters: The material of welding wire 2 is A1Si5, the diameter is 1.2mm, the welding current is 144A, the voltage is 16.4V, the wire feeding speed is 6.5m / min, the arc length is corrected to -30%, the wire withdrawal frequency is 70Hz, and argon is used as protection Gas, the flow rate is 15L / min, and the welding time is 0.8s.

[0055] The working process of this embodiment is as follows: Figure 5 (a)~(f) and Figure 6 (a) ~ (h) as shown:

[0056] The first step, welding material pretreatment: after drilling a nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com