Integral type fully-automatic tea processing machine

A fully automatic tea making machine technology, which is applied in tea processing before extraction, etc. It can solve problems such as difficulty in guaranteeing the internal quality and appearance quality of the product, difficulty in controlling the heat and processing time, and difficulty in ensuring the quality of tea leaves, etc., to achieve energy saving The effect is remarkable, the appearance is beautiful, and the effect of the rope is tightly knotted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

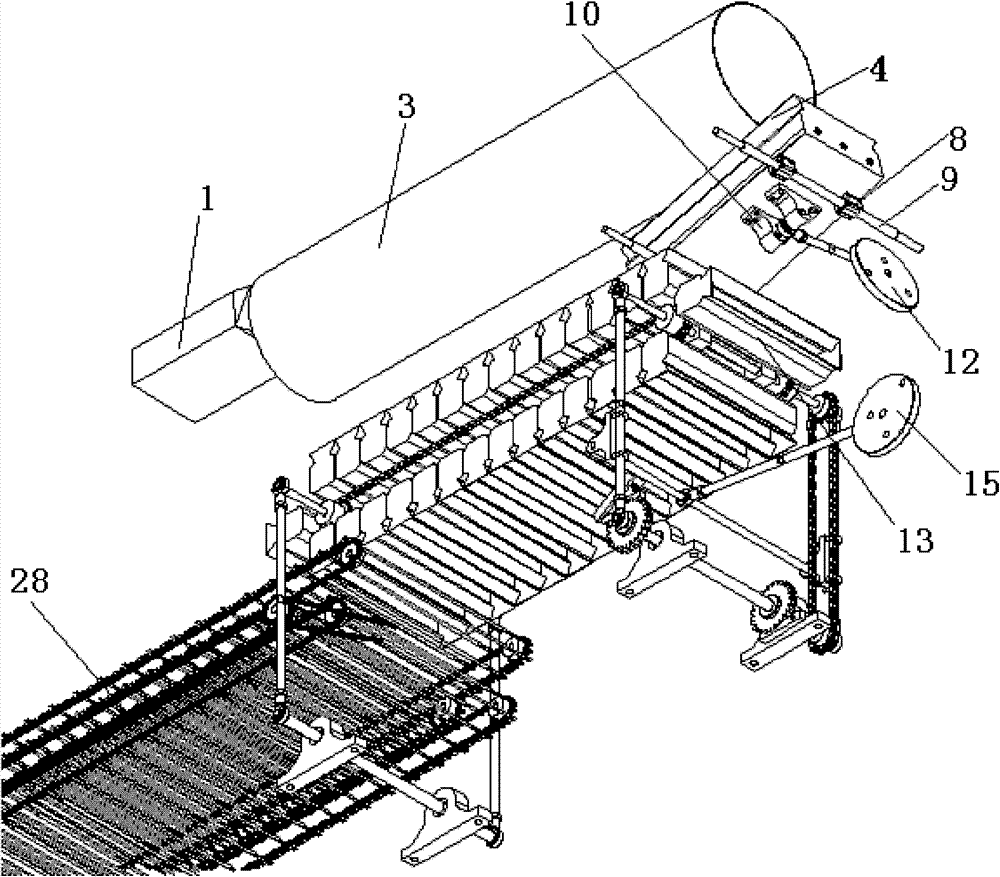

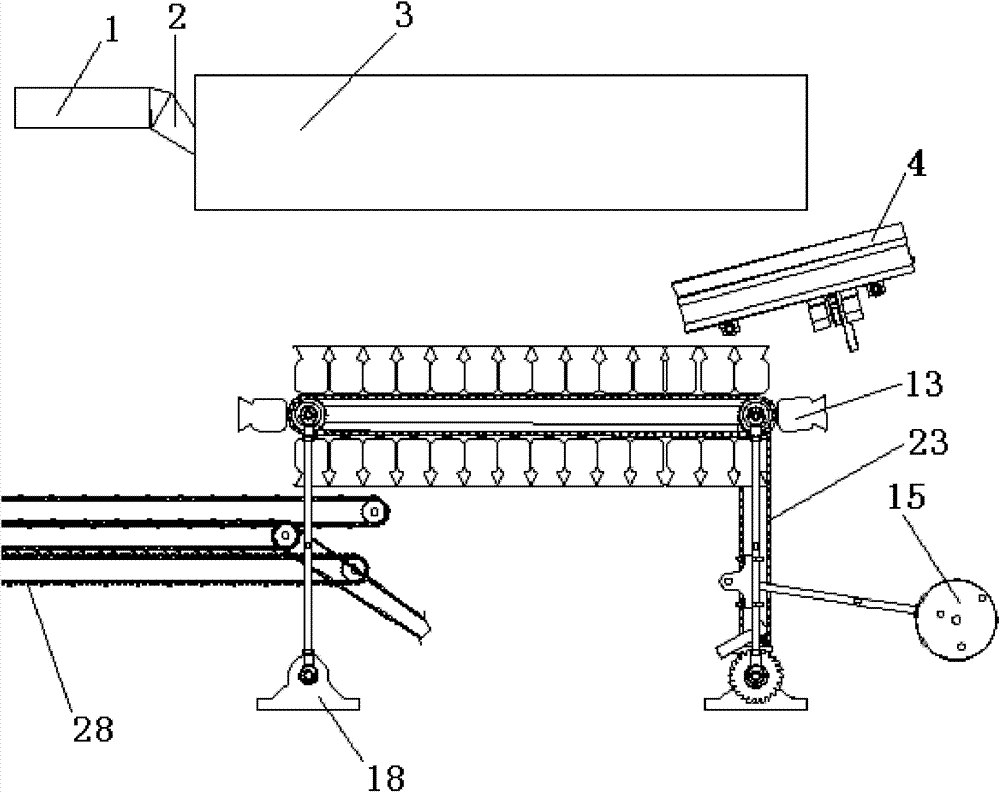

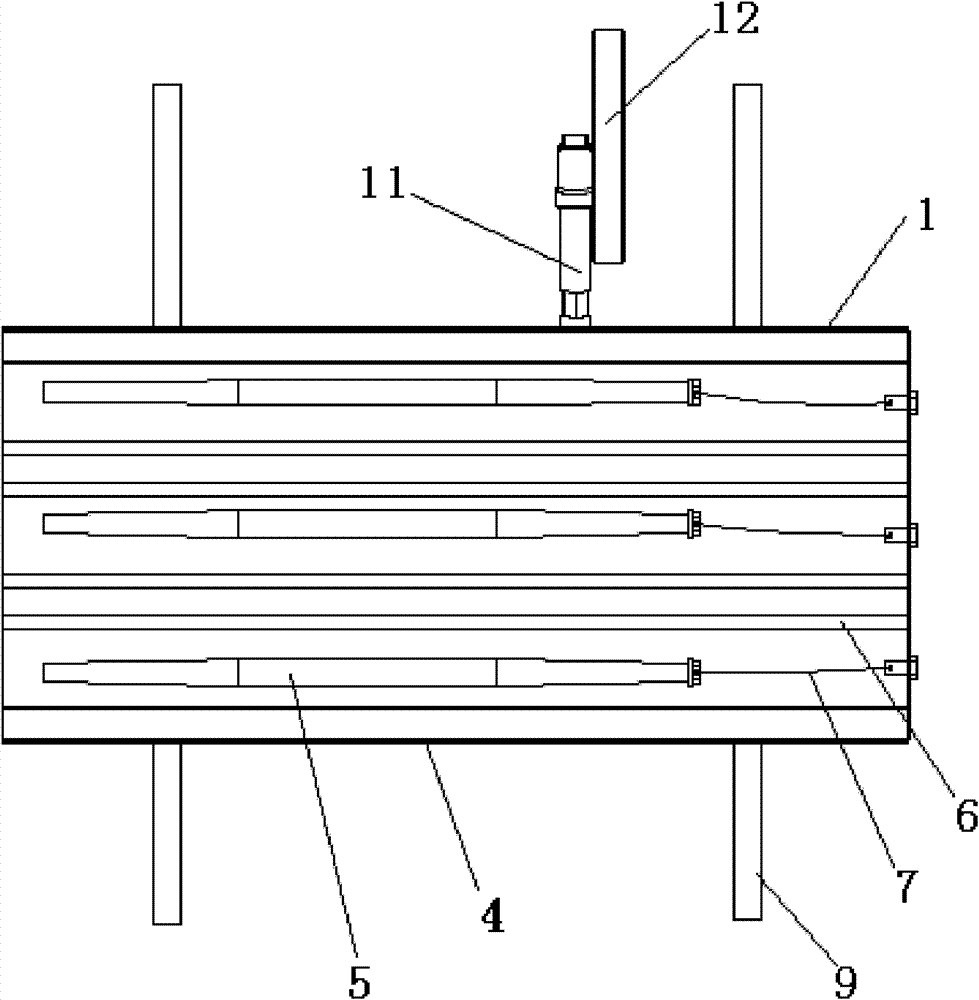

[0023] An integral fully automatic tea making machine, comprising a feed hopper 1, the bottom of the feed hopper 1 is provided with an inclined discharge chute 2, and the discharge end of the discharge chute 2 corresponds to the feeding port of the fixing mechanism 3 below it , the discharge port of the killing mechanism 3 is corresponding to the feed end of the U-shaped box in the adjustable U-shaped box below it, and the adjustable U-shaped box includes a U-shaped groove 4, Straightening rod 5, eccentric wheel driving device and heating device, one end of U-shaped groove 4 is sealed, and one end is open. Two herringbone partitions 6 are arranged in U-shaped groove 4, and the partition 6 divides U-shaped groove into three U-shaped Organizer box, arranger bar 5 is respectively arranged in the arranger box, and arranger bar 5 is fixedly installed on the corresponding U-shaped groove 4 end faces of the arranger box by chain 7, and four guide seats 8 are installed on the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com