Formation method of OTP (One Time Programmable) device

A device and patterning technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of particle pollution, easy peeling of photoresist layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

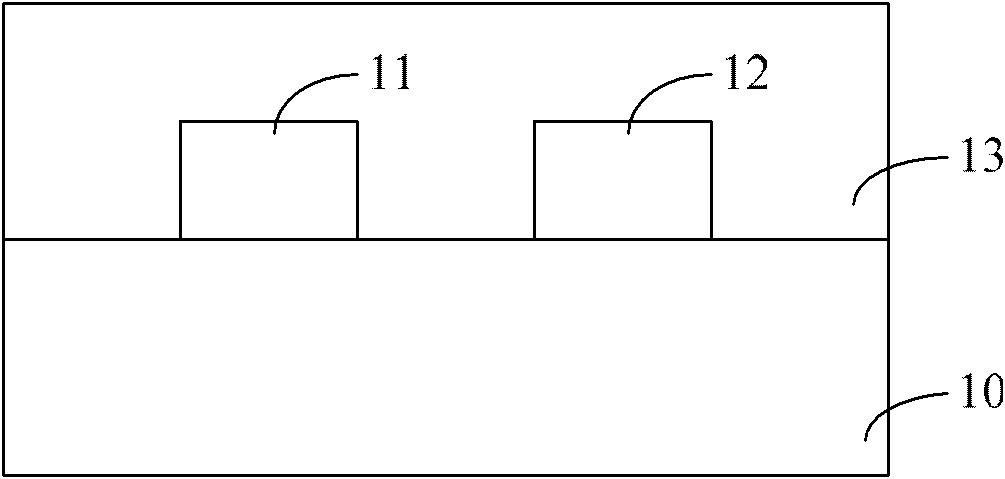

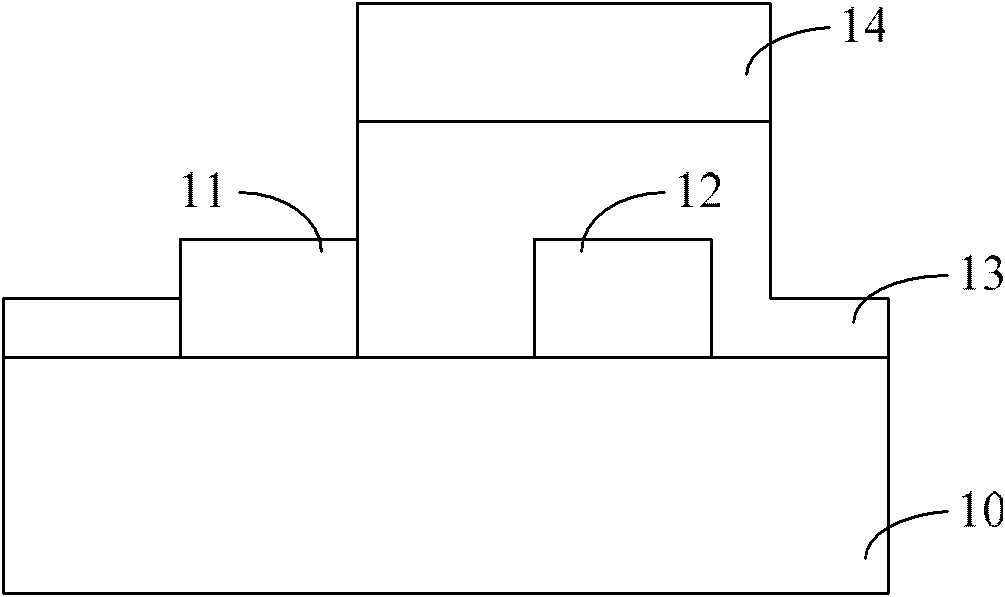

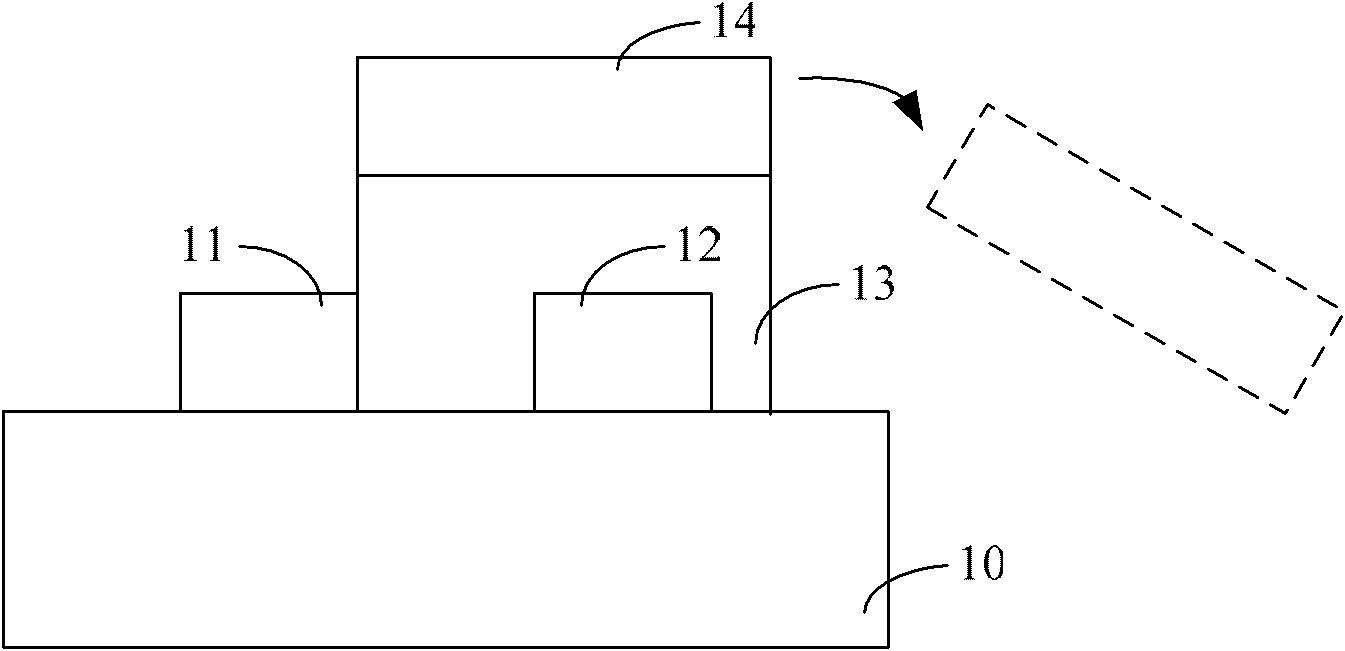

[0034] In the prior art, due to poor adhesion between the photoresist layer and the dielectric layer, it is easy to fall off during the wet etching process, resulting in particle pollution.

[0035] This technical scheme first introduces nitrogen element on the surface of the dielectric layer covering the floating gate and the selection gate, and then forms a patterned photoresist on it, thereby effectively improving the performance of the dielectric layer and patterned photolithography. The adhesion between the glues avoids the problem of particle contamination caused by the peeling off of the patterned photoresist during the wet etching process. In addition, it can also avoid the damage of the dielectric layer above the floating gate and prevent the data of the OTP device from being damaged. Retention is affected.

[0036] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com