Wood and bamboo fiber mercerizing pulp and preparation method thereof

A technology of bamboo fiber silk and actinic pulp, which is applied in the fields of cellulose raw material pulping, natural cellulose pulp/paper, fiber raw material treatment, etc., can solve the problems that the preparation method has not been published in public reports, etc., and achieve a wide range of application of the method, The effect of long fiber length and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1, raw material: roll shape coniferous pulp

[0061] The roll-shaped coniferous pulp passes through the swelling pool at a speed of 20-40m / min, the temperature of the clear water in the swelling pool is 35°C, the swelling time is 15s, and continues to run forward at a running speed of 20-40m / min to enter mercerization In the chemical zone, at a temperature of 25°C, treat it with a NaOH solution with a concentration of 14wt% for 15s. The NaOH solution is placed in an alkali-resistant mercerizing pool. Both the swelling pool and the mercerizing pool are ceramic water tank pools with temperature measuring devices, with a size of 5000mm*3000mm*1200mm.

[0062] The reel pulp after mercerizing treatment is squeezed with a pressure of 5kN / m to remove most of the residual lye, and then enters the neutralization zone. The temperature of the neutralization zone is 20°C, and the concentration of the neutralization solution is 8wt % waste sulfuric acid or waste hydroch...

Embodiment 2

[0067] Embodiment 2, raw material: flat coniferous pulp

[0068] Step 1: Dissolve the flat coniferous pulp with clean water to a concentration of 3.0-4.0%, at a temperature of 35°C, pulp with a hydraulic pulper, and then swell for 40 minutes. ZJGS energy-saving hydraulic pulper, Zhucheng Jinlong Machinery Manufacturing Co., Ltd.

[0069] Step 2: Transport the slurry obtained in Step 1 to the mercerizing tank filled with NaOH solution, the transport speed is 30m / min, and treat it with NaOH solution with a concentration of 13wt% at 35°C and normal pressure for 15s to perform mercerization treatment. The above mentioned slurry was carried by polyester mesh.

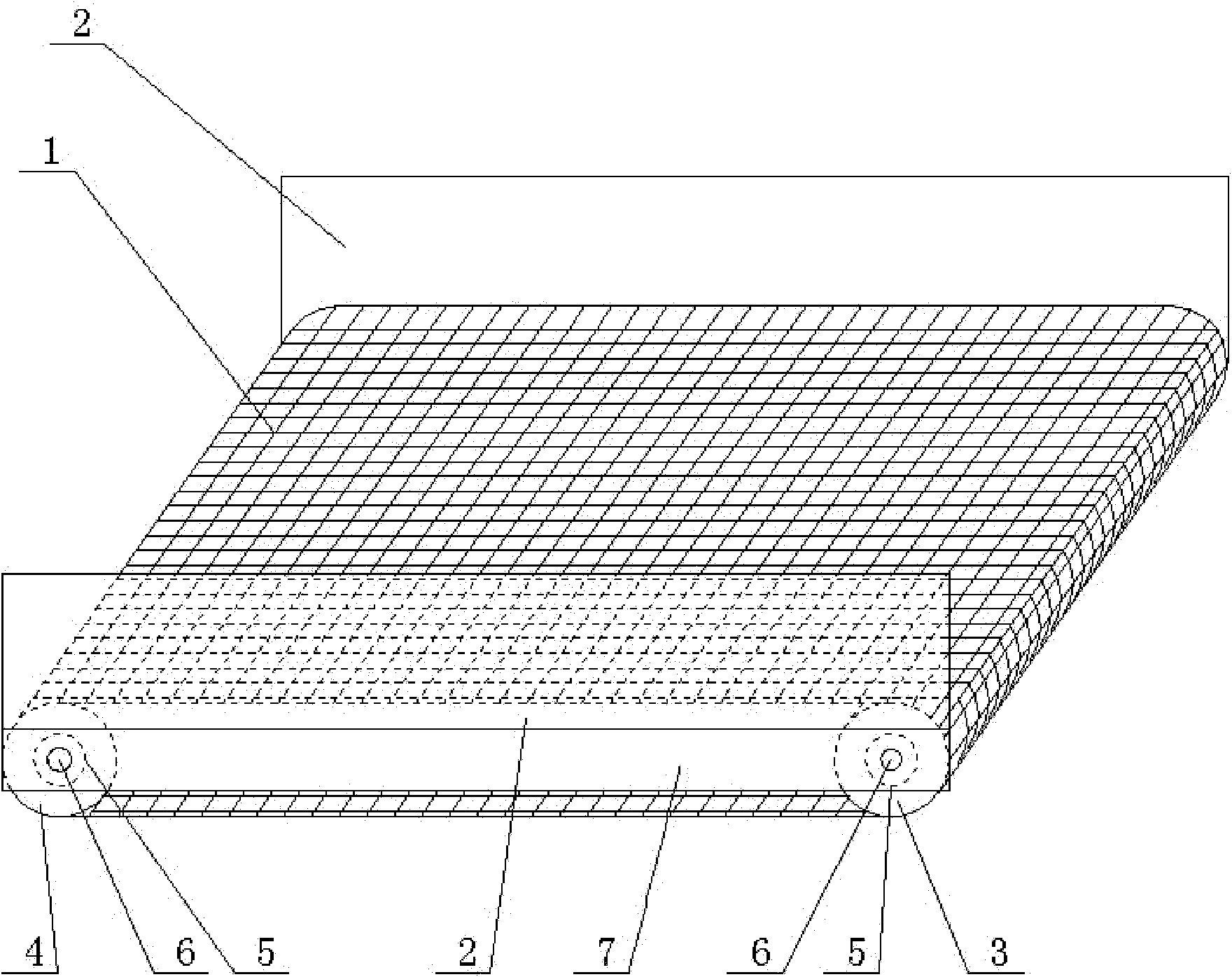

[0070] There are rubber baffles 2 on both sides of the polyester mesh 1, and the two ends of the polyester mesh belt are closed into a ring, which is set on 2 rollers, one is the driving roller 3, which is used to drive the movement of the polyester mesh belt, and the other It is the passive roller 4, and the polyester ne...

Embodiment 3

[0076] Embodiment 3: Mercerization of loose hardwood pulp

[0077] The loose hardwood pulp is diluted with clear water to a pulp concentration of 3.5 wt%, and the temperature is swollen at 35° C. for 45 minutes.

[0078] Gained slurry is conveyed in the mercerizing pool that fills NaOH solution, and mercerizing treatment is identical with embodiment 2.

[0079] The slurry obtained after mercerizing uses a concentrator (ZYW gravity rotary screen concentrator, Zhucheng Jinlong Machinery Manufacturing Co., Ltd.) to remove most of the residual lye. %, and then enter the neutralization tank for neutralization. The neutralization zone conditions are low temperature 7°C, normal pressure, neutralization solution is waste hydrochloric acid, the concentration of waste acid is 8%, and the neutralization time is 13s.

[0080] The pulp obtained after neutralization was washed with a cylinder thickener (ZNW30, Zibo Light Industry Machinery Co., Ltd.), clean water, normal pressure, temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tightness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com