Hyaluronate gel particle and preparation method thereof

A technology of hyaluronate and gel particles, applied in medical science, surgery, etc., can solve the problems of short decomposition period, complex preparation method, fast degradation and absorption, etc., to reduce production and operation costs, and to achieve high operational feasibility , the effect of easy injection into the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

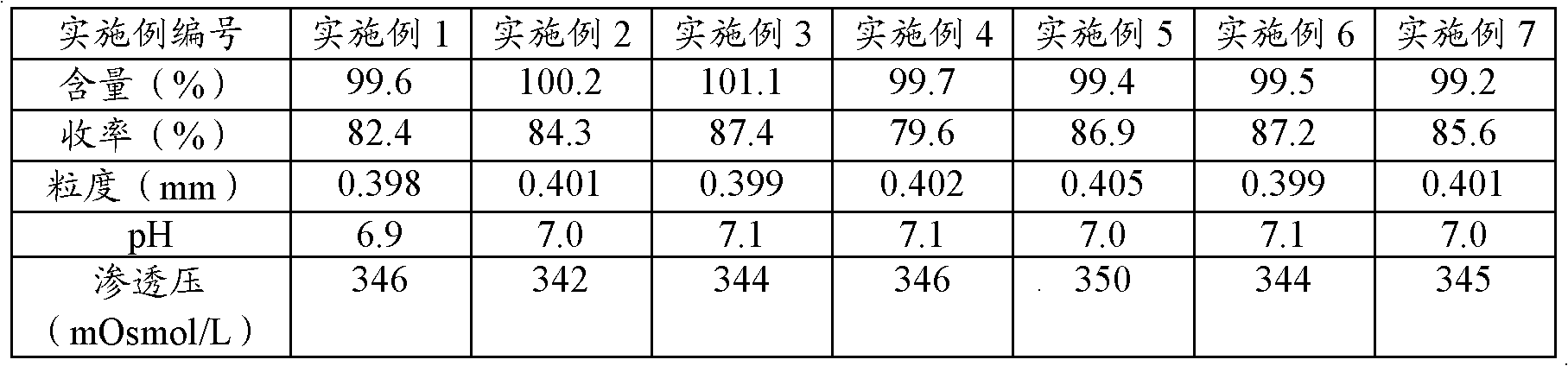

Examples

Embodiment 1

[0031] Add 1.0 g sodium hyaluronate dry powder (molecular weight 1.8 million Daltons, purchased from Shandong Freda) to 10 ml of 0.8% sodium hydroxide solution, stir until it becomes transparent and fully dissolve, and then add 80 μl of sodium hyaluronate Glycol diglycidyl ether (CA: 2425-79-8), stirred evenly, and reacted at a constant temperature of 30°C for 7 hours to obtain a transparent gel block, which was added to 500ml of deionized water, kept at a constant temperature of 70°C for 6 hours, purified Change the water once during the swelling process, filter, and wash the resulting gel piece with 500ml PBS damping fluid (the osmotic pressure is 350, and every 1000ml contains NaH 2 PO 4 2H 2 O 0.099mg, NaH 2 PO 4 2H 2 (01.123g, NaCl 10.45g) static dialysis for 12 hours, during which the PBS buffer solution was changed twice, filtered, and the gel piece was passed through an 80-mesh stainless steel sieve to obtain sodium hyaluronate gel particles.

Embodiment 2

[0033] Add 1.0 g sodium hyaluronate dry powder (molecular weight 1.8 million Daltons, purchased from Shandong Freda) to 10 ml of 0.8% sodium hydroxide solution, stir until it becomes transparent and fully dissolve, and then add 80 μl of sodium hyaluronate Diol diglycidyl ether (CA: 2425-79-8), stir well, react at 40°C for 4 hours to obtain a transparent gel block, add it to 500ml deionized water, keep at 70°C for 6 hours, purify and swell Change water once in the process, filter, with 500ml PBS damping fluid (osmotic pressure is 350, every 1000ml contains NaH 2 PO 4 2H 2 O 0.099mg, NaH 2 PO 4 2H 2 O 1.123g, NaCl 10.45g) static dialysis for 12 hours, during which the PBS buffer solution was replaced twice, filtered, and the gel piece was passed through an 80-mesh stainless steel sieve to obtain sodium hyaluronate gel particles.

Embodiment 3

[0035] Add 1.0 g sodium hyaluronate dry powder (molecular weight 1.8 million Daltons, purchased from Shandong Freda) to 10 ml of 0.8% sodium hydroxide solution, stir until it becomes transparent and fully dissolve, and then add 80 μl of sodium hyaluronate Diol diglycidyl ether (CA: 2425-79-8), stirred evenly, and reacted at a constant temperature of 50°C for 4 hours to obtain a transparent gel block, which was added to 500ml of deionized water, kept at a constant temperature of 70°C for 6 hours, and purified Change the water once during the swelling process, filter, and wash the resulting gel piece with 500ml PBS damping fluid (the osmotic pressure is 350, and every 1000ml contains NaH 2 PO 4 2H 2 O 0.099mg, NaH 2 PO 4 2H 2 (01.123g, NaCl 10.45g) static dialysis for 12 hours, during which the PBS buffer solution was changed twice, filtered, and the gel piece was passed through an 80-mesh stainless steel sieve to obtain sodium hyaluronate gel particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com