Aeration rotary brush

A technology of aeration and rotating brushes and blades, which is applied in water aeration, water/sludge/sewage treatment, biological water/sewage treatment, etc. It can solve the problem of large changes in water level in oxidation ditch, increase water flow resistance, and increase operating energy consumption, etc. problems, to achieve the effect of increasing the working water depth, reducing the running resistance, and improving the oxygenation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

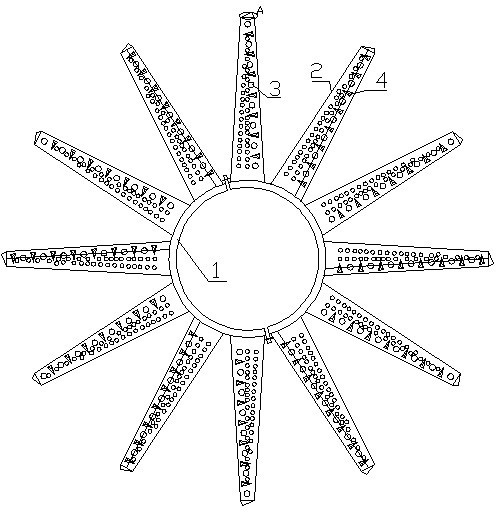

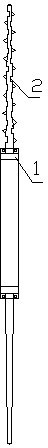

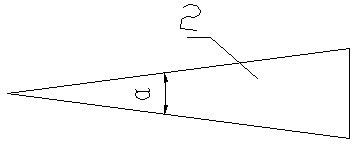

[0022] Example 1: see Figure 1-6 , the aeration rotating brush of the present invention, is made up of central axis 1 and the straight rotating brush blade 2 that periphery is radially fixed, wherein the section of the rotating brush blade is triangular, and the rotating brush blade is fixed on the rotating shaft, so that when the aeration rotating brush runs, the blade The triangular cone enters the water first. There are circular pits 3 and triangular bumps 4 on both sides of the triangle of the rotating brush blade (wherein the triangle of the bump is in the same direction as the triangle of the blade section), the bumps on the adjacent blades are arranged in a staggered manner, and the backside (triangular top surface) 5 has Circular dimples 6 are alternated, and the end faces of the blades are also triangular ( Figure 4 ). The rotating brush blade is composed of two symmetrical pieces molded with glass fiber reinforced resin. The rotating brush blade is fixed on the h...

Embodiment 2

[0023] Example 2: see Figure 7 , as in Embodiment 1, wherein the triangular projections 4 on both sides of the rotating brush blade are arranged opposite to the triangle in the section of the rotating brush blade, and the triangular tip of the rotating brush blade has serrations 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com