Direct-drive crystallizer vibration generating device and non-sinusoidal vibration method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

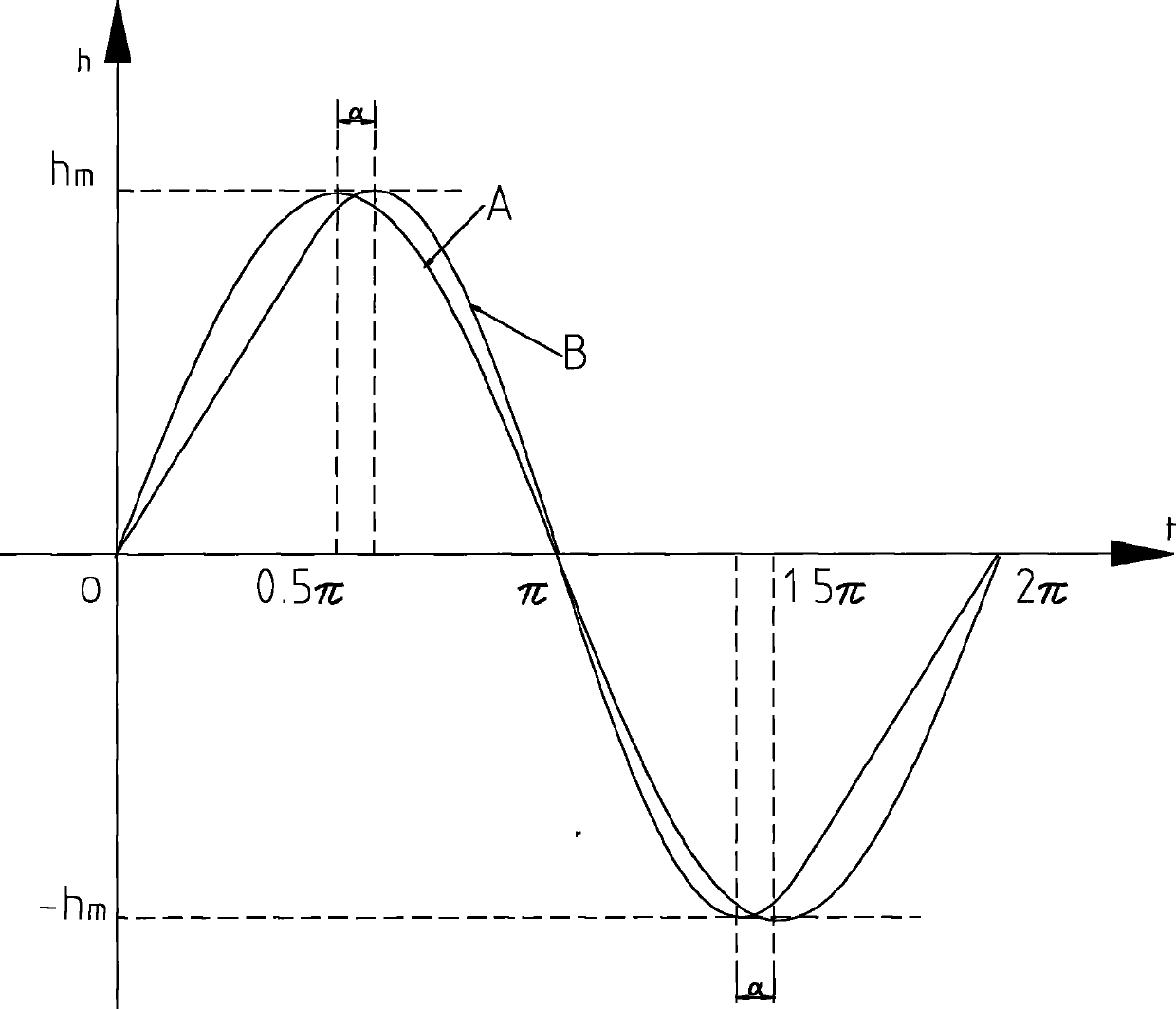

Method used

Image

Examples

Embodiment Construction

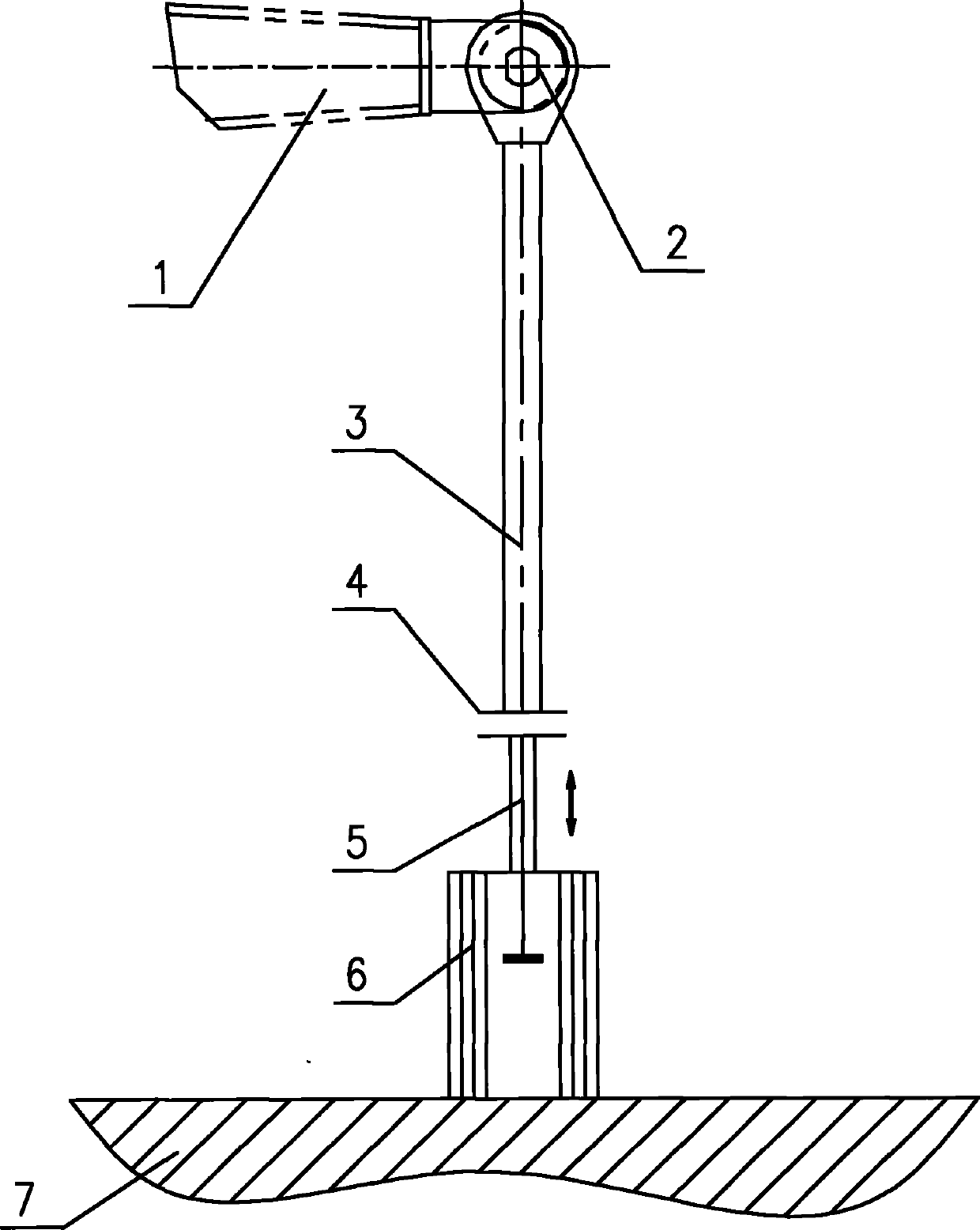

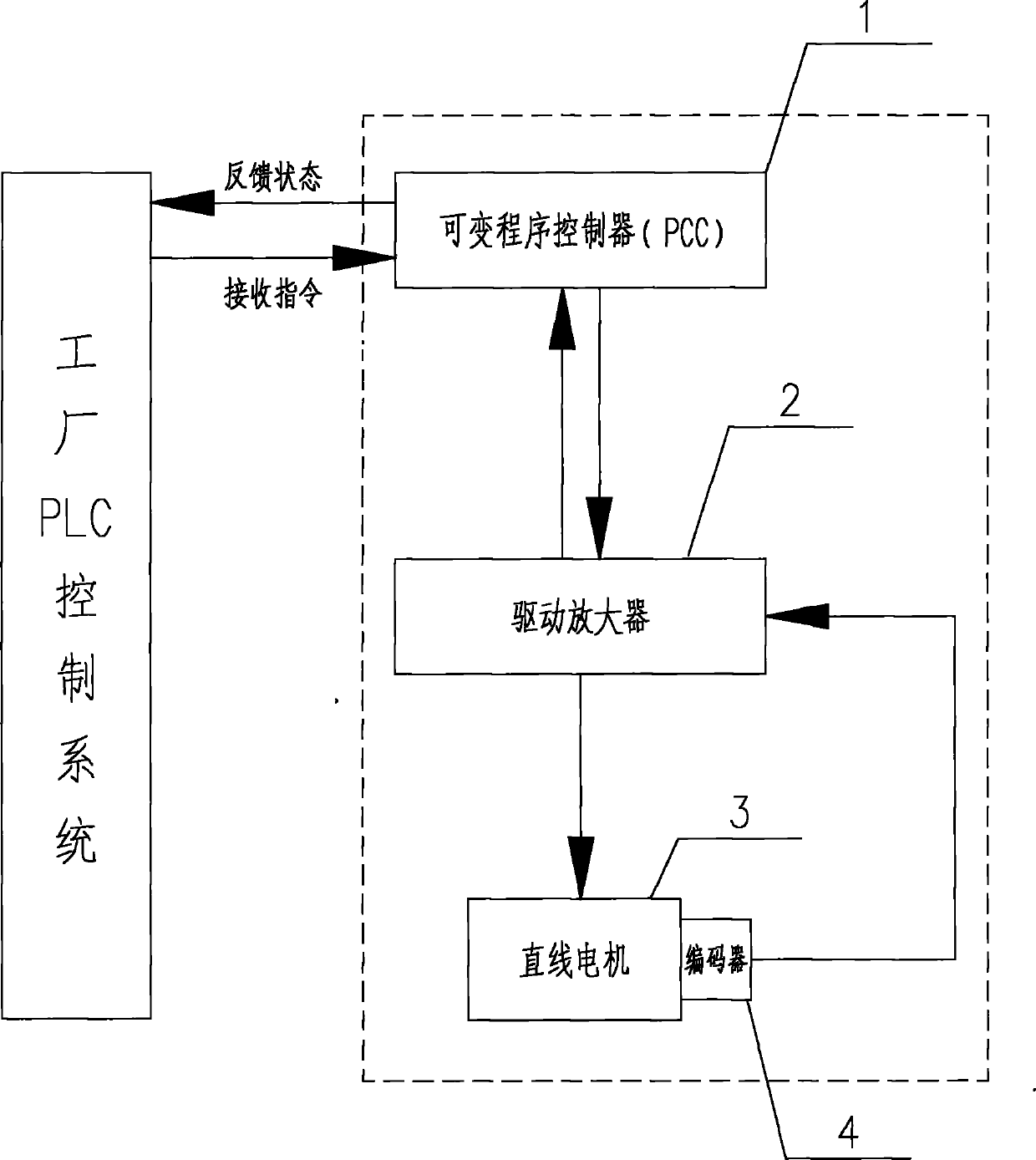

[0019] The invention discloses a direct drive crystallizer vibration generating device, comprising a vibration table, the vibration table is connected with a connecting rod, the connecting rod is connected to a linear motor, and the linear motor drives the connecting rod to drive the vibration The table moves, the linear motor is connected to a control part, and the control part controls the motion mode of the linear motor. The linear motor adopts a low-speed, high-torque linear motor.

[0020] The connecting rod is connected with a linear motor. Alternatively, the connecting rod can also be connected with multiple synchronous parallel linear motors, thereby increasing the bearing capacity.

[0021] The existing crystallizer vibration devices all use AC asynchronous motors as drive motors. The working principle of asynchronous motors (induction motors) is to generate induced currents in the rotor through the rotating magnetic field of the stator to generate electromagnetic to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com