Organic/inorganic mixed proton exchange membrane

A proton exchange membrane, inorganic technology, used in fuel cell parts, fuel cells, electrical components, etc., can solve the problems of catalyst layer peeling, impedance rise, performance degradation of passive direct methanol fuel cells, etc., to achieve excellent mechanical strength, Good water retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

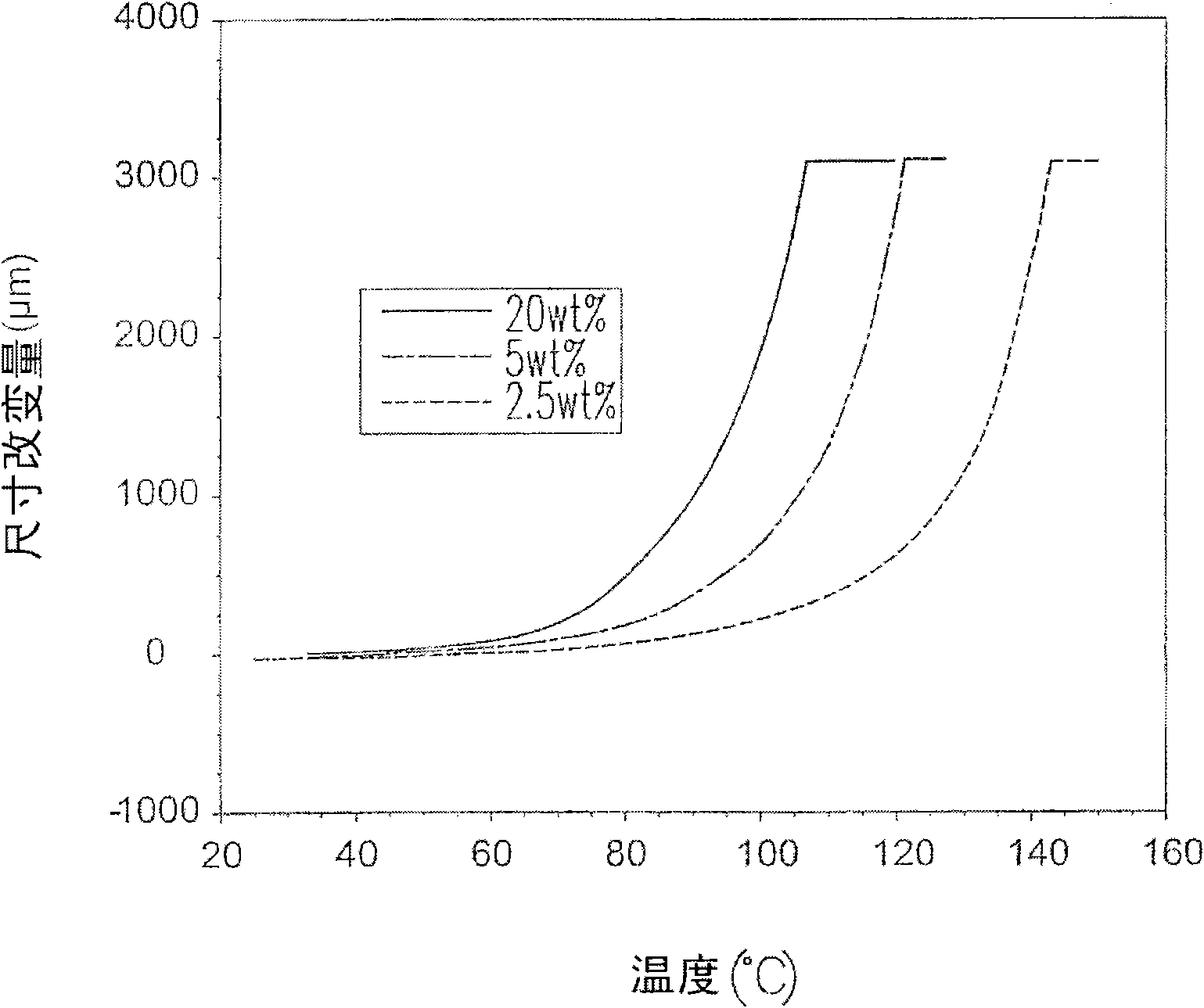

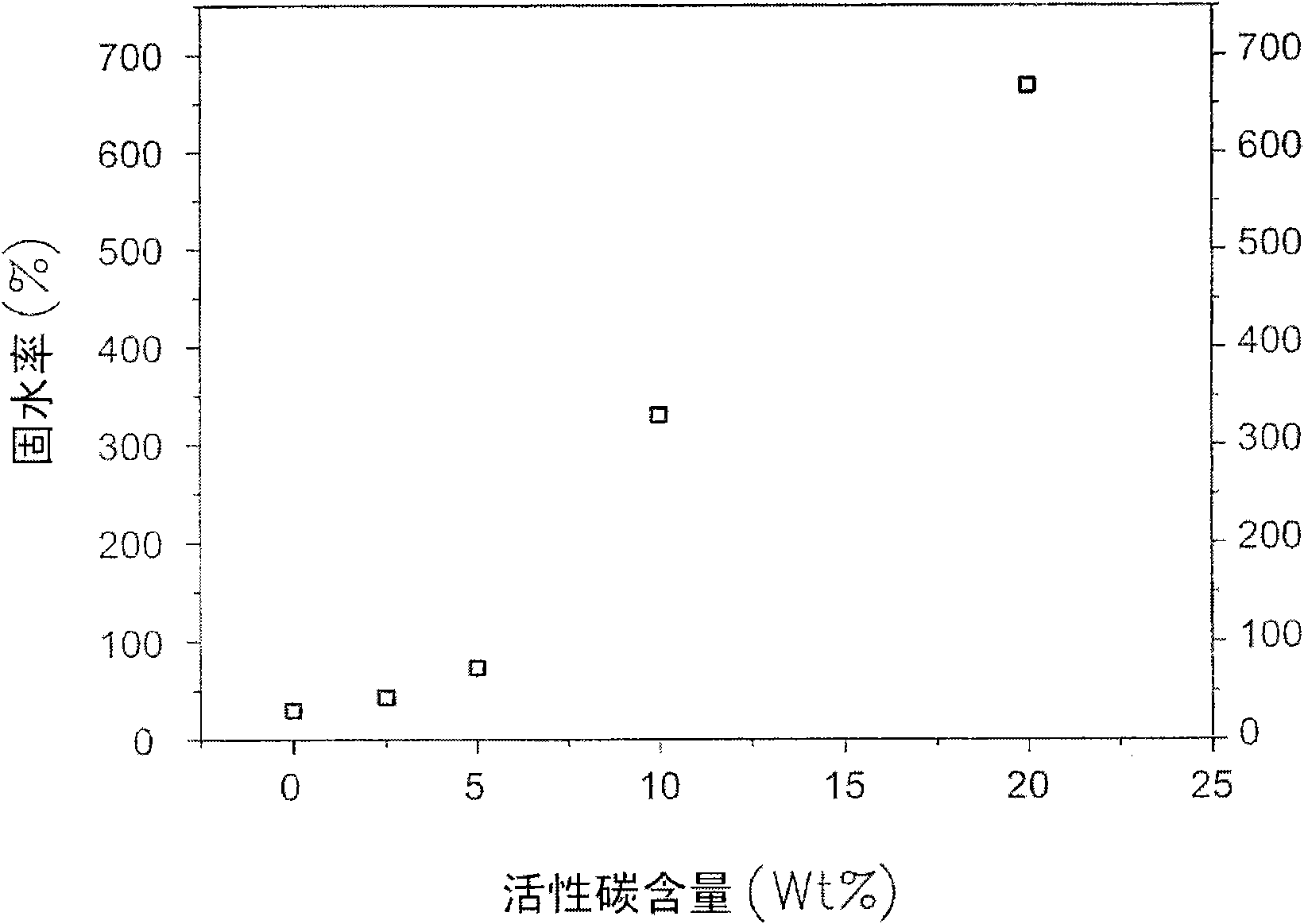

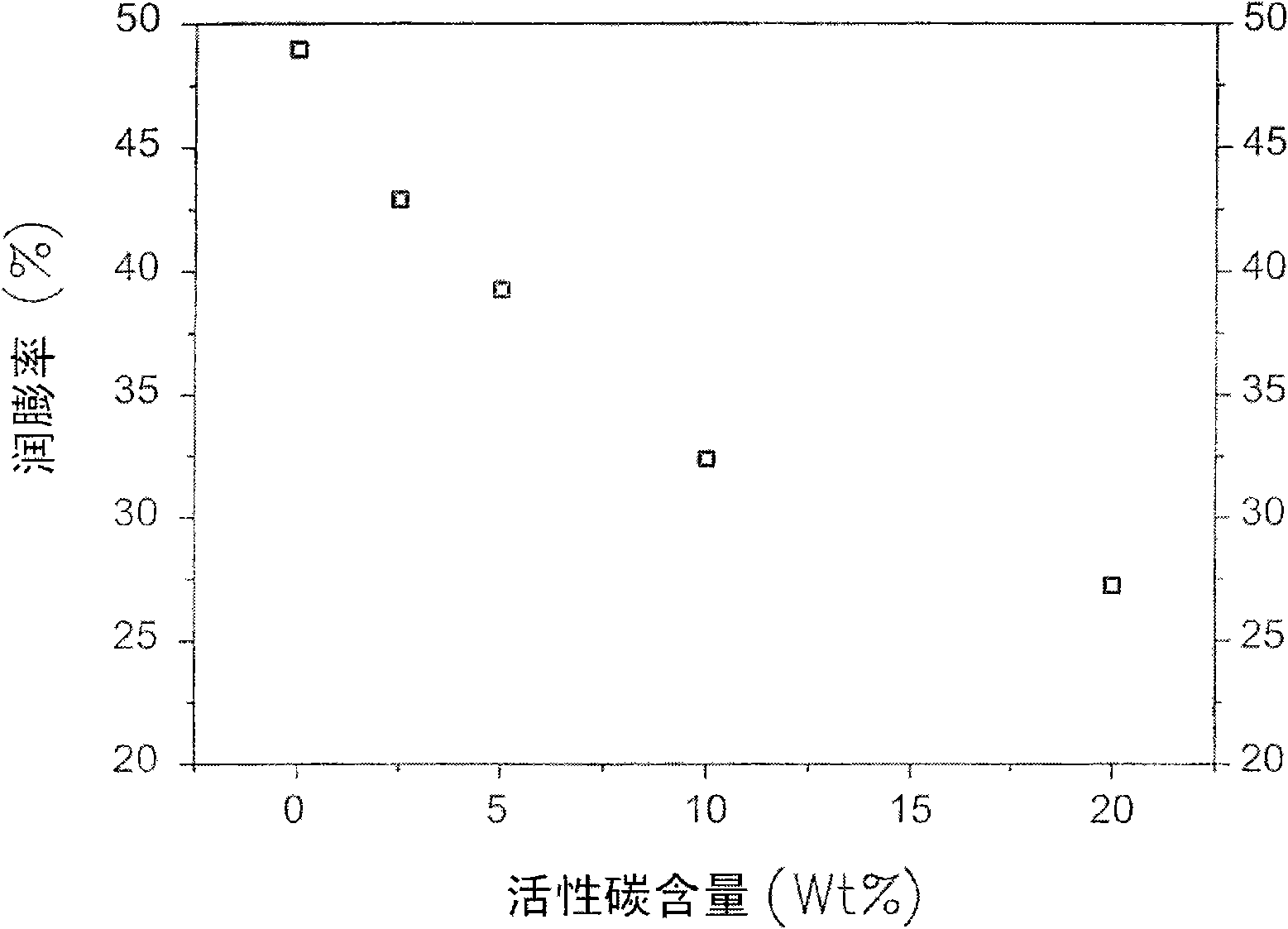

example 1

[0029] 20wt% (relative to the overall solid content) of non-modified porous carbon (activated carbon) is dispersed in the solution of perfluorosulfonic acid resin Nafion (NAF, DE2020CS commodity manufactured by DuPont Company) to form a slurry (ink), Stir evenly, and after aging for 12 hours, the prepared slurry is coated on glass and the solvent is evaporated. Immerse in 1N H at 80°C 2 SO 4 In (aq), the proton substitution reaction is carried out for 1 hour or several hours. Next, immerse in excess pure water at 80°C for 1 hour or several hours to fully clean and obtain a black soft film. Afterwards, the properties of the film were measured. The results of flexibility and glass transition temperature measurement are shown in Table 1, and the dimensional change with temperature is as follows figure 1 As shown, the results of water retention and swelling are shown in Table 2 and figure 2 and image 3 Shown in Table 3 are the results of conductivity measurements at variou...

example 2 to example 4

[0031] Membranes were formed in the same manner as in Example 1, except that the content of unmodified porous carbon (activated carbon) was changed to 10 wt%, 5 wt% and 2.5 wt%, respectively.

example 5、 example 6

[0033] Membrane was prepared in the same way as Example 1, but the non-modified porous carbon was changed to ECP 600 (carbon black, NSA (Net Surface area): 1200m 2 / g) and CL-08 (carbon black, NSA: 210m 2 / g, manufactured by China Synthetic Rubber Company) its content is 5wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com