Responser for improving underdamped system

An under-damped, circuit technology, applied in the field of circuits that drive under-damped systems, to achieve the effect of fast set-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

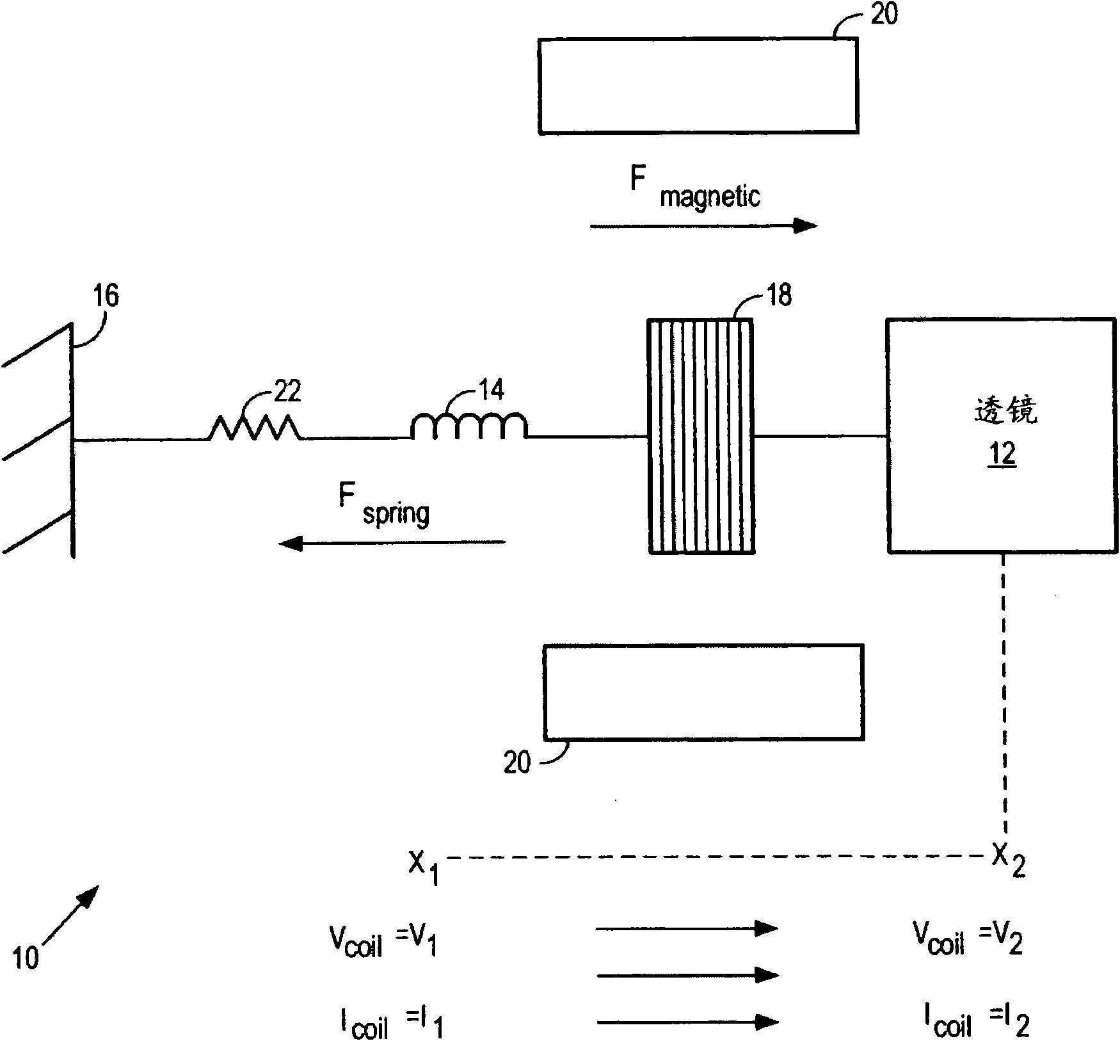

[0022] figure 1 is a diagram of one embodiment of a spring-loaded electromagnetic lens assembly 10 including a focusable lens 12 . The lens assembly 10 may be a system such as a camera or video recorder ( figure 1 part not shown). An example of such a lens assembly is shown in US Patent No. 7,612,957, which is incorporated herein by reference.

[0023] In addition to the lens 12, the lens assembly 10 also includes a spring 14 for forcing the lens toward the reference position 16, and the lens assembly 10 also includes a coil 18 and at least one permanent magnet 20 ( figure 1 Two magnets are shown in ) that work together to force the lens away from this reference position. Since the skilled person can model the lens assembly 10 as a second-order spring-mass system, figure 1 A damper 22 is included to represent the level of damping inherent in the lens assembly - the damper is not an actual part of the lens assembly, but represents the combination of all sources of damp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap