Single crystal silicon texture-making additive and single crystal silicon texture-making technology

An additive and process technology, applied in the field of solar cell production and texturing technology, can solve the problems of high requirements on the surface state of the original silicon wafer, low conversion efficiency of the cell, and high defect rate of texturing appearance, so as to reduce the defect rate of texturing surface, The texturing process is stable and reliable, and the effect of fully automatic liquid dispensing is realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

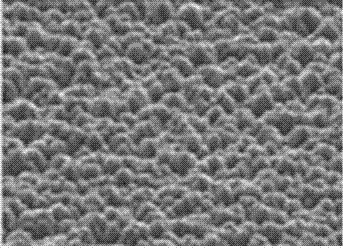

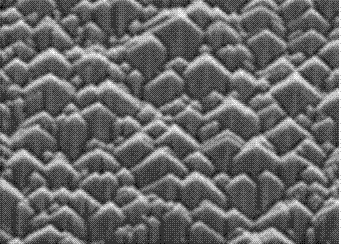

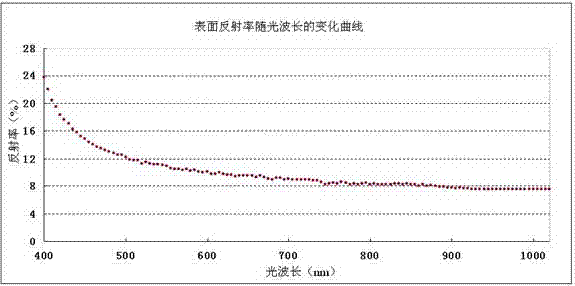

Image

Examples

Embodiment 1

[0028] (1) Prepare monocrystalline silicon texturing additives, which are composed of wetting agent and defoaming agent with a weight ratio of 2:1, and the wetting agent is alkyl glycoside (APG-0810). The defoamer is sorbitan fatty acid ester (S-20).

[0029] (2) Single crystal silicon texturing process:

[0030] Heat 135L of deionized water to 70°C, add sodium hydroxide to obtain monocrystalline silicon texturing corrosion solution, wherein the concentration of sodium hydroxide is 1% by mass; add the above monocrystalline silicon texturing additive A mixed solution was obtained in the texture etching solution, wherein the concentration of monocrystalline silicon texturing additive was 0.3% by volume; the pre-cleaned original silicon wafer was put into the above mixed solution for 600s for texturing. The texturing process is carried out continuously in batches. After the texturing of the first batch of original silicon wafers is completed, sodium hydroxide and monocrystal...

Embodiment 2

[0041] (1) Prepare the monocrystalline silicon texturing additive, which is composed of a wetting agent and a defoaming agent with a weight ratio of 1:2, and the wetting agent is polysorbate 80. The defoamer is polyether polyol (F68).

[0042] (2) Single crystal silicon texturing process:

[0043] Heat 135L of deionized water to 80°C, add potassium hydroxide to obtain monocrystalline silicon texturing corrosion solution, wherein the concentration of potassium hydroxide is 2% by mass; add the above-mentioned monocrystalline silicon texturing additive and isopropanol Obtain mixed solution in monocrystalline silicon texturing corrosion solution, wherein, the volume percentage concentration of monocrystalline silicon texturing additive is 2%, the volume percentage concentration of isopropanol is 6%; Texturing is carried out in the mixed solution for 1200s. The texturing process is carried out continuously in batches. After the texturing of the first batch of original silicon...

Embodiment 3

[0046] (1) Prepare the monocrystalline silicon texturing additive, which is composed of a wetting agent and a defoaming agent with a weight ratio of 1:1. The wetting agent is isomeric alcohol polyoxyethylene ether (model 1305). The defoamer is silicone surfactant (BYK-300).

[0047] (2) Single crystal silicon texturing process:

[0048] Heat 135L of deionized water to 75°C, add sodium hydroxide to obtain monocrystalline silicon texturing corrosion solution, wherein the mass percentage concentration of sodium hydroxide is 1.5%; add the above monocrystalline silicon texturing additive and isopropanol Obtain mixed solution in monocrystalline silicon texturing corrosion solution, wherein, the volume percent concentration of monocrystalline silicon texturing additive is 1%, and the volume percent concentration of isopropanol is 3%; Texturing is carried out in the mixed solution for 1000s. The texturing process is carried out continuously in batches. After the texturing of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com