Micromachining method of textures on metal surface

A metal surface and micro-machining technology, which is applied in the fields of craft and decorative art for producing decorative surface effects, can solve problems such as complex lines or patterns, and achieve the effect of good lines and textures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Metal substrate

[0035] The aluminum plate (model 5052) is punched into the shape of the mobile phone shell (84mm×54mm×0.5mm) by stamping technology.

[0036] (2) Production of jigs

[0037] According to the shape of the stamped mobile phone case, a jig is made, and the material is aluminum alloy, which is used to clamp the stamped mobile phone case.

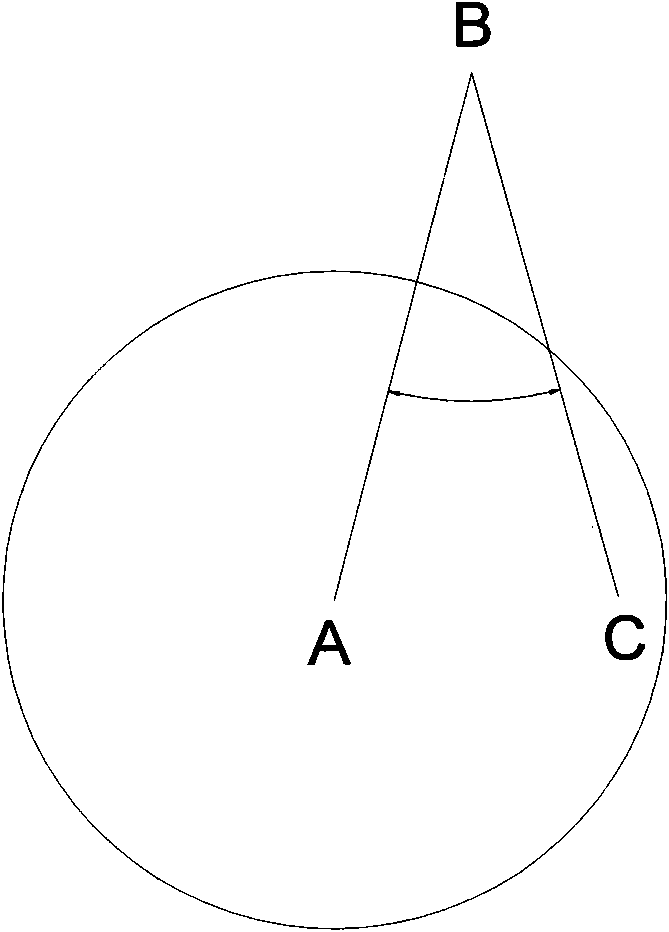

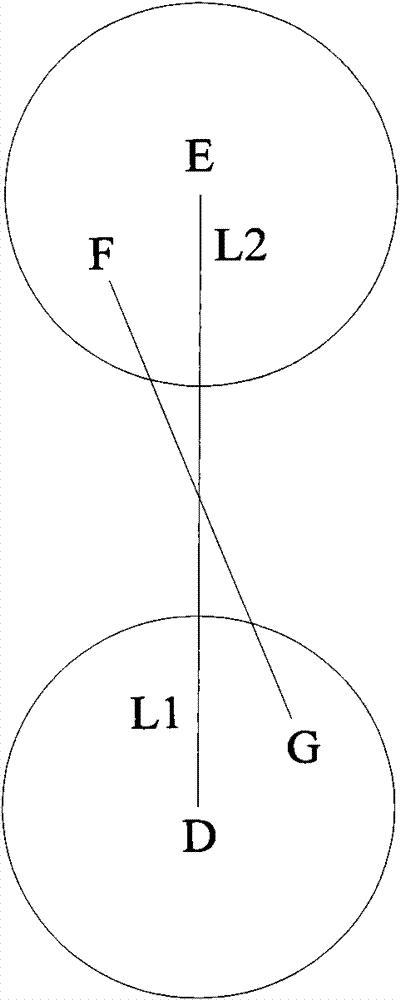

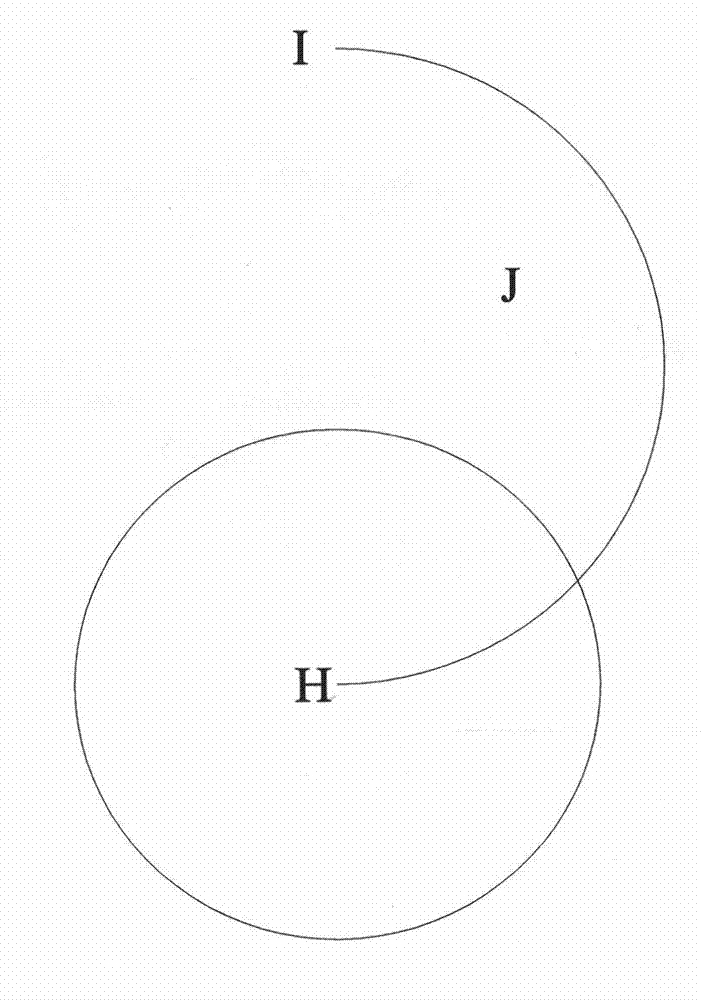

[0038] (3) Spindle path design and programming

[0039] Use CAD software to draw a V-shaped path with an included angle of 30°. According to the drawn CAD path, use G code to program and import it into numerical control equipment.

[0040] (4) Texture processing

[0041] Put the stamped mobile phone case on the jig prepared in step (2) to fix it, spray a small amount of WD-40 universal anti-rust lubricant on the aluminum material, press the start button, and the programmed processing can be performed program. The machining depth is 0.05mm, the spacing is 0.2mm, the spindle speed is 2000r / min, the feed speed of X...

Embodiment 2

[0043] (1) Metal substrate

[0044] Use wire cutting technology to cut the aluminum alloy (model 5052) into a ring-shaped mobile phone photo frame (the inner frame is a square with a side length of 7.85mm, and the chamfering radius of the four vertices of the square is R1.64mm; the outer frame is a square with a side length of 12.75mm. The chamfering radius of the four vertices of this square is R3.0mm.

[0045] (2) Production of jigs

[0046] According to the shape of the cut ring-shaped mobile phone photo frame, a jig is made, and the material is aluminum alloy, which is used to clamp the cut ring-shaped mobile phone photo frame.

[0047] (3) Spindle path design and programming

[0048] Use CAD software to draw a V-shaped path with an included angle of 45°. According to the drawn CAD path, use G code to program and import it into CNC equipment.

[0049] (4) Texture processing

[0050] Put the punched mobile phone case on the jig prepared in step (2) to fix it, spray a sm...

Embodiment 3

[0052] (1) Metal substrate

[0053] The aluminum plate (model 5056) is punched into the shape of the mobile phone shell (84mm×54mm×0.5mm) by stamping technology.

[0054] (2) Production of jigs

[0055] According to the shape of the stamped mobile phone case, a jig is made, and the material is aluminum alloy, which is used to clamp the stamped mobile phone case.

[0056] (3) Spindle path design and programming

[0057] Use CAD software to draw a V-shaped path with an included angle of 90°. According to the drawn CAD path, use G code to program and import it into CNC equipment.

[0058] (4) Texture processing

[0059] Put the stamped mobile phone case on the jig prepared in step (2) to fix it, spray a small amount of WD-40 universal anti-rust lubricant on the aluminum material, press the start button, and the programmed processing can be performed program. The machining depth is 0.01mm, the spacing is 0.3mm, the spindle speed is 3000r / min, the feed speed of X-axis and Y-ax...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com