Rice steaming cabinet

A technology for steaming rice cabinets and cabinets, used in cooking utensils, household appliances, applications, etc., can solve the problems of food not being cooked, aging of electric heating tubes, failures, etc., to ensure continuity and stability, prevent aging, and prevent aging. Ensure no leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

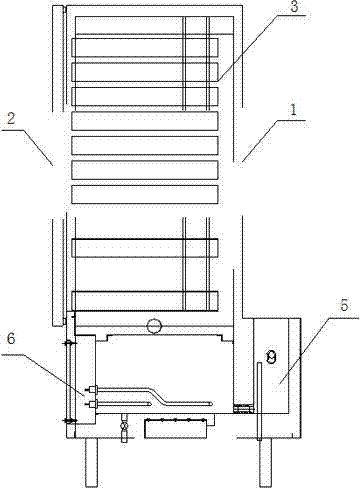

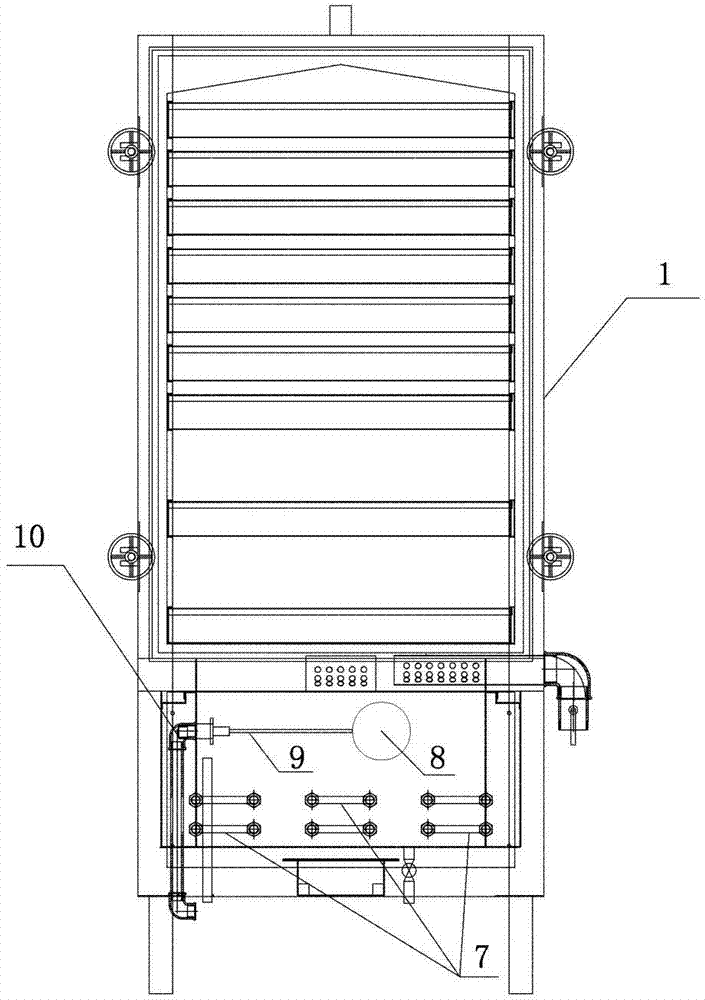

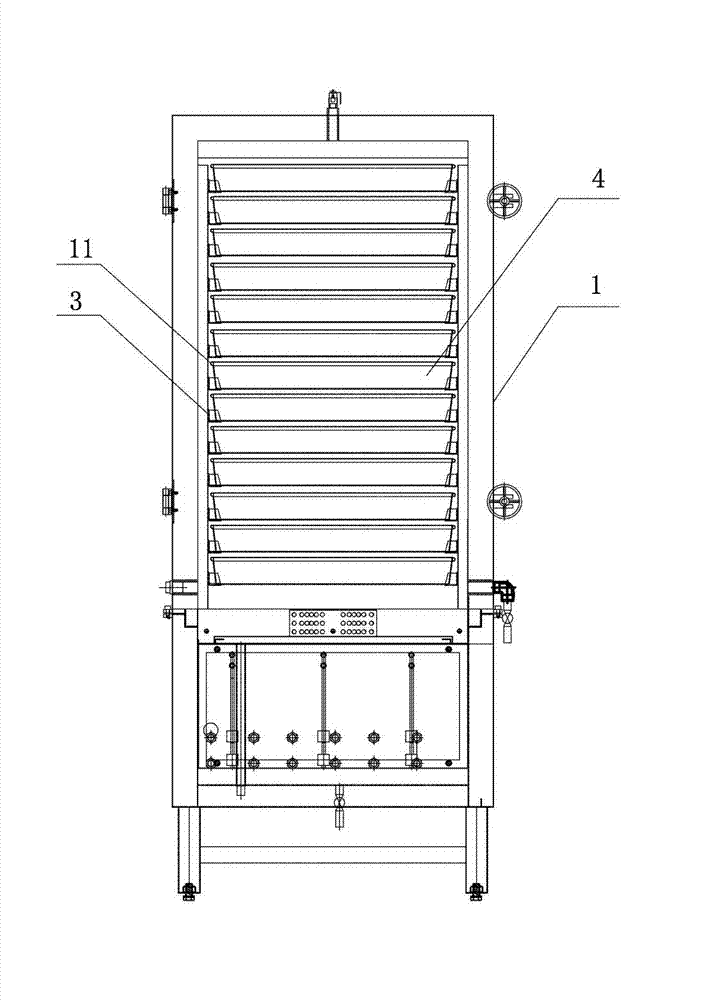

[0036] like Figure 1-5 The rice steaming cabinet shown in this embodiment is composed of a cabinet body, internal devices, control circuits and pipeline arrangements as a whole. The cabinet body includes an outer shell 1 and a door 2, both of which are made of stainless steel. There are multiple layers of brackets 3 in the cabinet, and there is a certain interval between the brackets 3 of each layer. The brackets 3 are used to place the fixed trays 4 . Generally, the rice cooker is used in a stable state, so the trays do not need to be fixed, but the present invention reforms the trays and brackets in order to solve the problem that the trays and brackets can be used effectively and safely.

[0037] In a general rice cooker or steamer box, the steamer tray does not match the bracket in the steamer box very well. There are problems such as shaking and hitting the wall and easily falling off the bracket. When personnel carry the rice tray, the tray is easily deformed. The prob...

Embodiment 2

[0062] The effect of this embodiment is as follows Figure 7 As shown, the control circuit includes a first relay KM1 and a second relay KM2, the first relay KM1 has a first normally open auxiliary contact and a first normally closed auxiliary contact, and the second relay KM2 has a second normally open auxiliary contact The contact and the second normally closed auxiliary contact, the first normally open auxiliary contact and the second normally closed auxiliary contact are connected in series, and are connected with the main electric heating tube to form the first coil, and the second normally open auxiliary contact is connected with the second normally closed auxiliary contact. A normally closed auxiliary contact is connected in series, and is connected with the standby electric heating tube to form the second coil. The normally closed auxiliary contacts of KM1 and KM2 are connected in series in each other's working coils, forming a mutual restriction relationship, that is, ...

Embodiment 3

[0065] The effect of this embodiment is as follows Figure 8 As shown, the control circuit includes a relay KM. The relay KM has a normally open auxiliary contact and a normally closed auxiliary contact. The normally open auxiliary contact and the main electric heating tube are connected in series to form the main coil, and the normally closed auxiliary contact is connected with the standby electric heating. The tubes are connected in series to form an auxiliary coil. Through the above improvements, the normally closed and normally open auxiliary contacts of the relay control two coils respectively, so as to ensure that only one electric heating tube is turned on when the steam generating device is working, and there will be no confusion during the middle wave peak.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com