Wafer level MMCM (microwave multichip module) packaging structure using photosensitive BCB (benzocyclobutene) as dielectric layer and method

A packaging structure and dielectric layer technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of not meeting the packaging loss requirements of microwave systems, reduce process complexity, improve performance and reliability, and match thermal expansion coefficients Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Embodiments of the present invention will be further specifically described below with reference to the accompanying drawings in order to fully demonstrate the advantages and positive effects of the present invention. The scope of the present invention is not limited to the following examples.

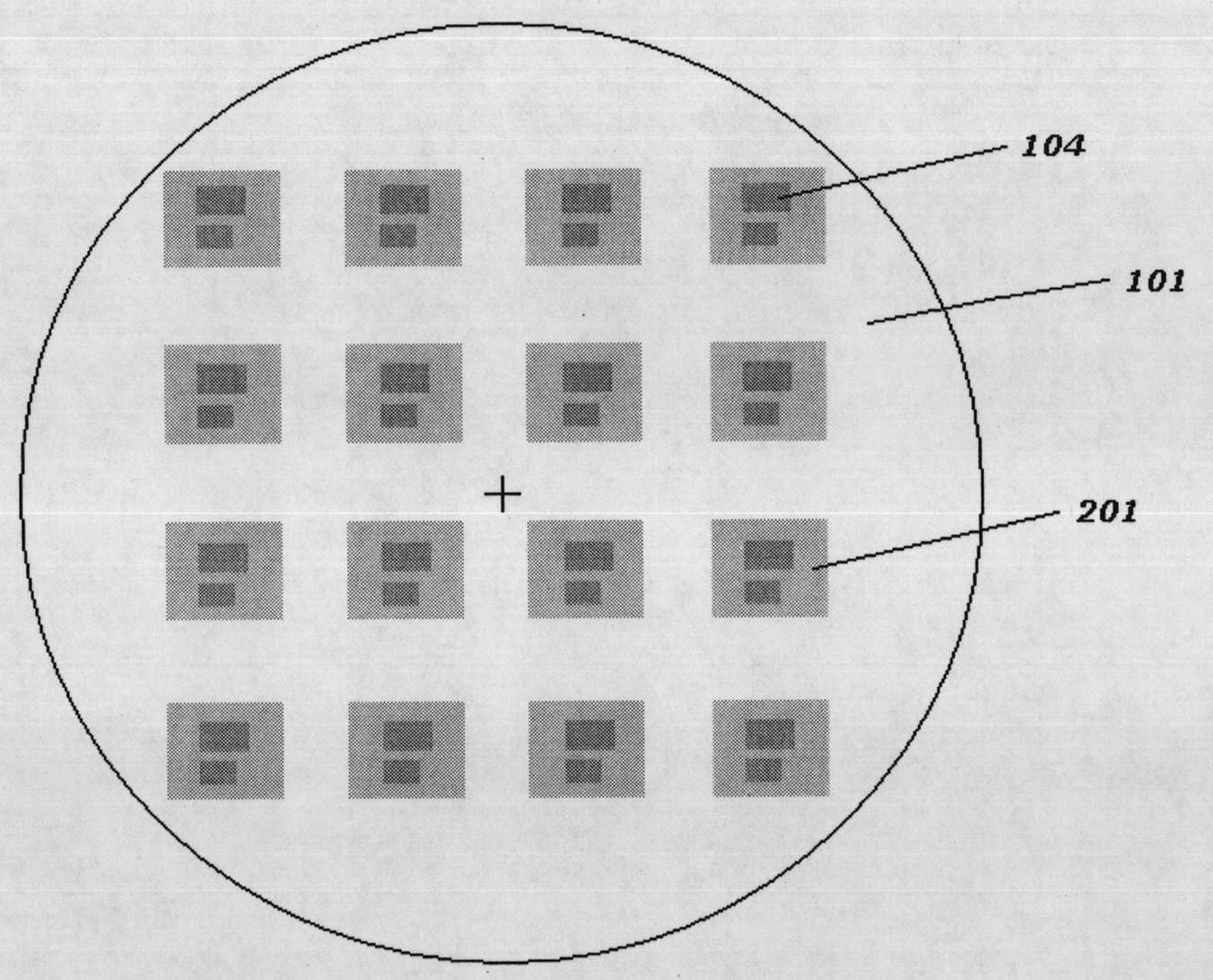

[0058] exist figure 1 Among them, the front side of the silicon substrate 101 is distributed in a 4×4 cell array, and each cell has two cavities of different sizes, which are suitable for embedding chips of different sizes. Since the preparation methods of the two cavities are the same, the larger cavity 104 is taken as an example in the embodiment, and the cavity 104 is formed by wet etching or dry etching.

[0059] exist figure 2 In the present invention, the ground shielding layer 201 is prepared on the silicon substrate containing the embedded cavity, and the ground shielding layer 201 is prepared by electroplating.

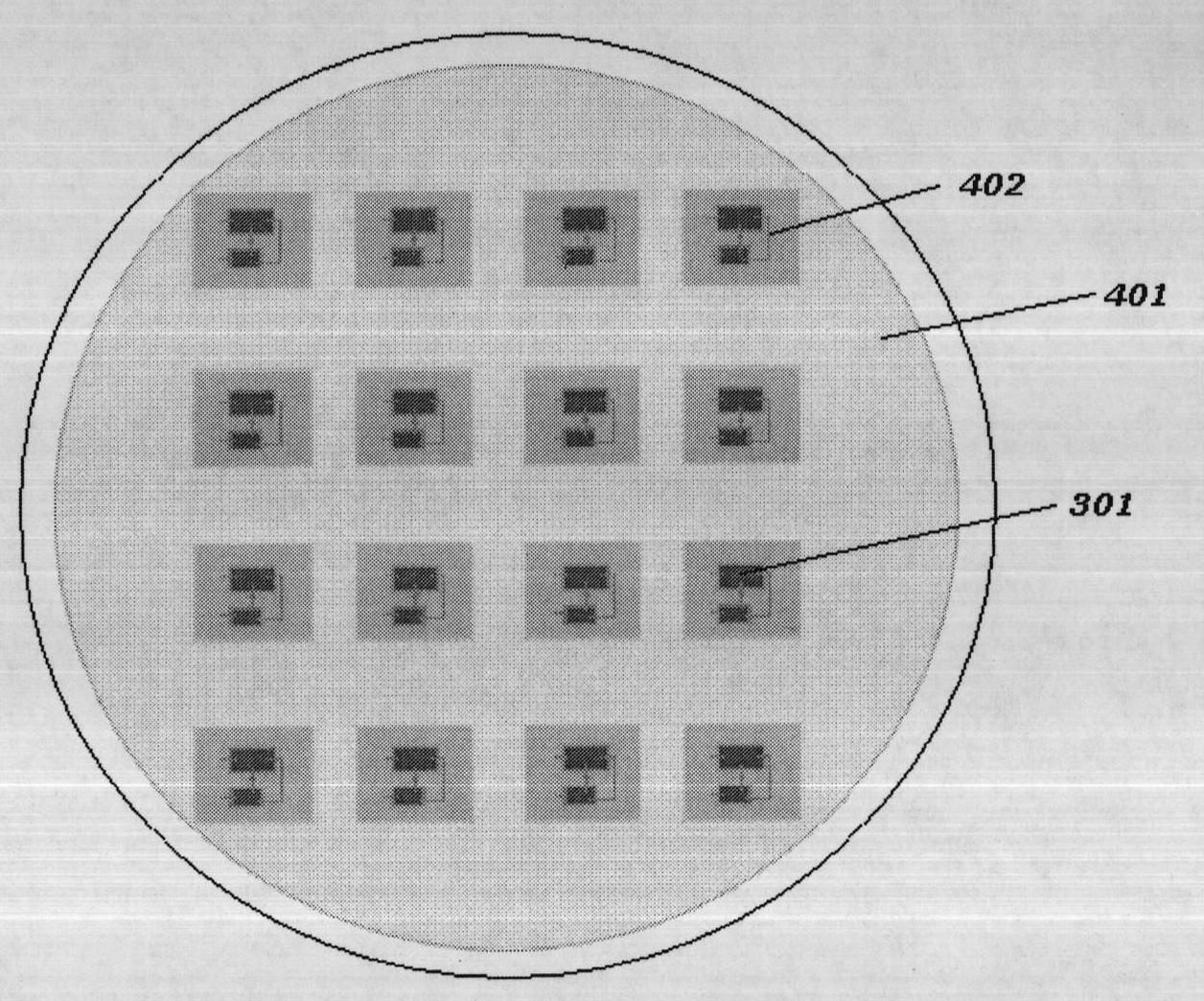

[0060] image 3 It is an overall packaging structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com