Carbon-based magnetic mesoporous composite microsphere and preparation method thereof

A composite microsphere and carbon-based technology, which can be used in the preparation of microspheres, microcapsule preparations, and the magnetism of inorganic materials. It can solve the problems of difficult control of the content of components, cumbersome steps, and complex composition, and achieve good application prospects. , easy and economical operation, good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

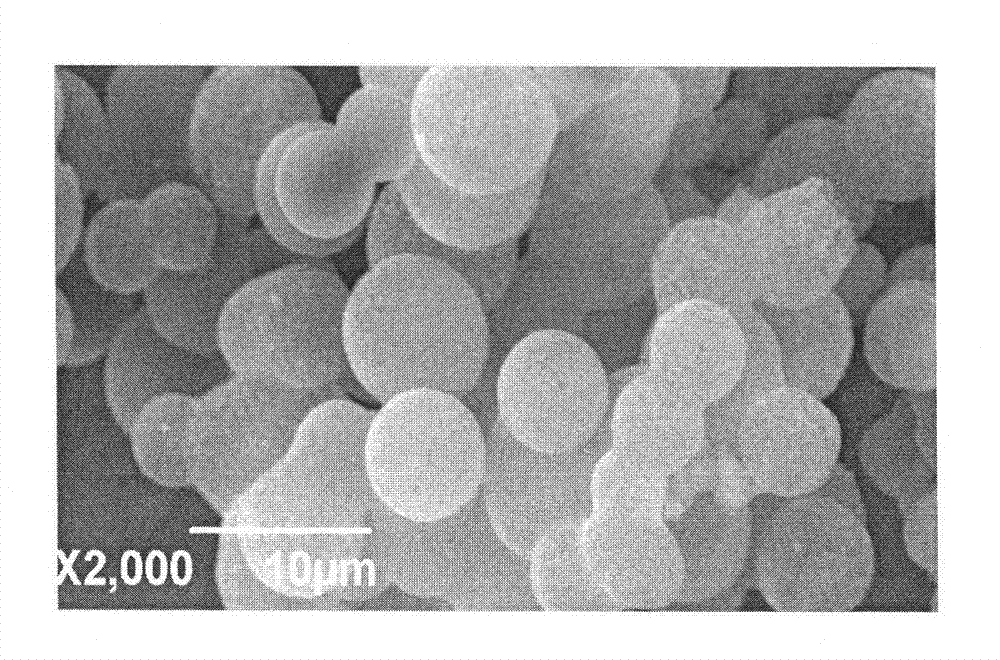

[0019] Embodiment 1: 4g ferric nitrate (Fe(NO 3 ) 3 ) and 10g glucose (C 6 h 12 o 6 ) was dissolved in 80mL water, stirred to dissolve completely, transferred to 100mL reaction, heated to 200°C, kept for 24h, and then cooled to room temperature in the air. Then take out the feed liquid and dehydrate. The resulting product was dried in air at 80°C for 6 hours to obtain Fe x o y / Carbon-based composite microspheres.

[0020] 5 g dry Fe x o y / Carbon-based composite microspheres are placed in the quartz tube of a tube furnace, and carbon dioxide gas is introduced, and the gas flow rate is 1L / min. Raise to 720°C at a rate of 5°C / min. Keep for 3h. It was then cooled to room temperature under a carbon dioxide atmosphere. Obtain gamma-Fe of the present invention 2 o 3 / carbon-based composite magnetic mesoporous microspheres.

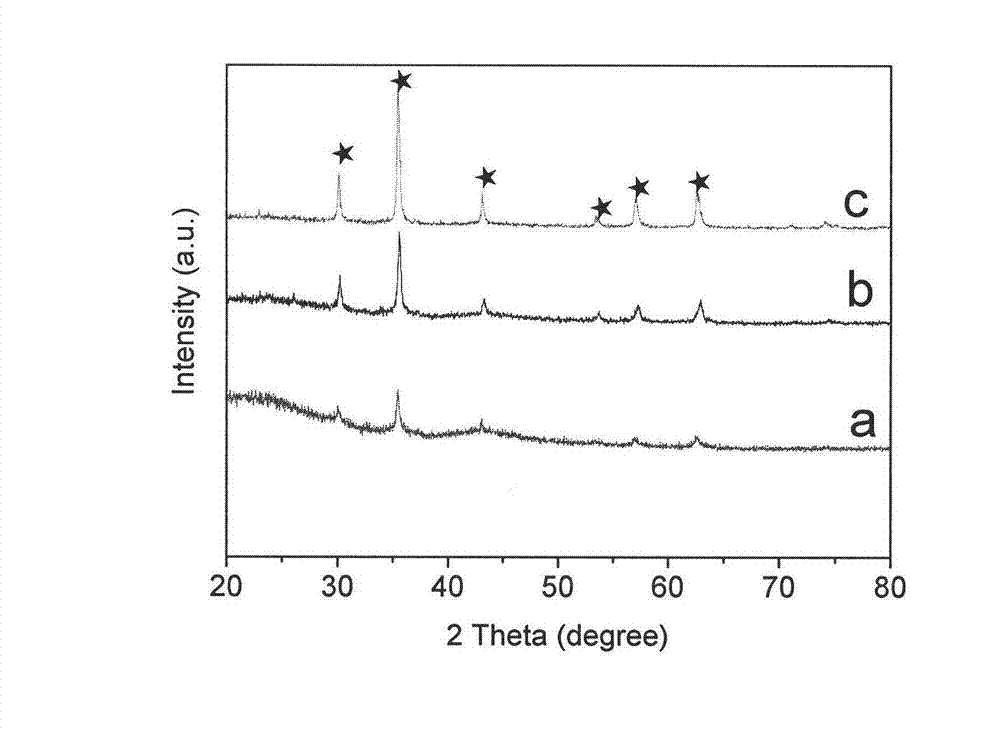

[0021] Adopt X-ray diffraction to characterize product structure with XpertMPD Philips automatic diffractometer, its XRD test result is as fol...

Embodiment 2

[0024] Embodiment 2: adopt sucrose (C 12 h 22 o 11 ) is the carbon source, according to the mass ratio m(Fe(NO 3 ) 3 ):m(C 12 h 22 o 11) = 0.8: 1 ratio feeding, ferric nitrate and sucrose consumption are 4g and 5g respectively, hydrothermal time 20h, carbon dioxide gas flow is 0.5L / min during activation, activation temperature is 800 ℃, keeps 2h. Others are as embodiment 1 implemented in the same way.

[0025] γ-Fe 2 o 3 / Carbon composite magnetic mesoporous microsphere analysis results are as follows:

[0026] XRD shows that the carbon sphere-based material contains γ-Fe 2 o 3 (See figure 1 Middle curve c), calculated γ-Fe 2 o 3 is 26 nanometers, and the specific surface area of microspheres is 287m 2 / g, the average pore diameter is 8nm, and the pore volume is 0.26cm 3 / g.

Embodiment 3

[0027] Embodiment 3: adopt glucose as carbon source, by mass ratio m (Fe (NO 3 ) 3 ):m(C 6 h 12 o 6 )=0.6:1 ratio feeding, ferric nitrate and glucose consumption were 6g and 10g, hydrothermal time 18h; carbon dioxide gas flow was 2L / min during activation, activation temperature was 650 ℃, kept 4h. Others are carried out in the same manner as in Example 1.

[0028] γ-Fe 2 o 3 / Carbon composite magnetic mesoporous microsphere analysis results are as follows:

[0029] XRD shows that the carbon sphere-based material contains γ-Fe 2 o 3 (See figure 1 The middle curve a) calculates γ-Fe 2 o 3 to 10 nm. The specific surface area of the microsphere is 276m 2 / g, the average pore diameter is 4nm, and the pore volume is 0.15cm 3 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com