Current-voltage electrode

A voltage electrode, current-voltage technology, applied in the field of sampling electrodes, can solve the problems of large contact surface for voltage sampling and large test error, and achieve the effects of accurate voltage signal sampling point, large contact area and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

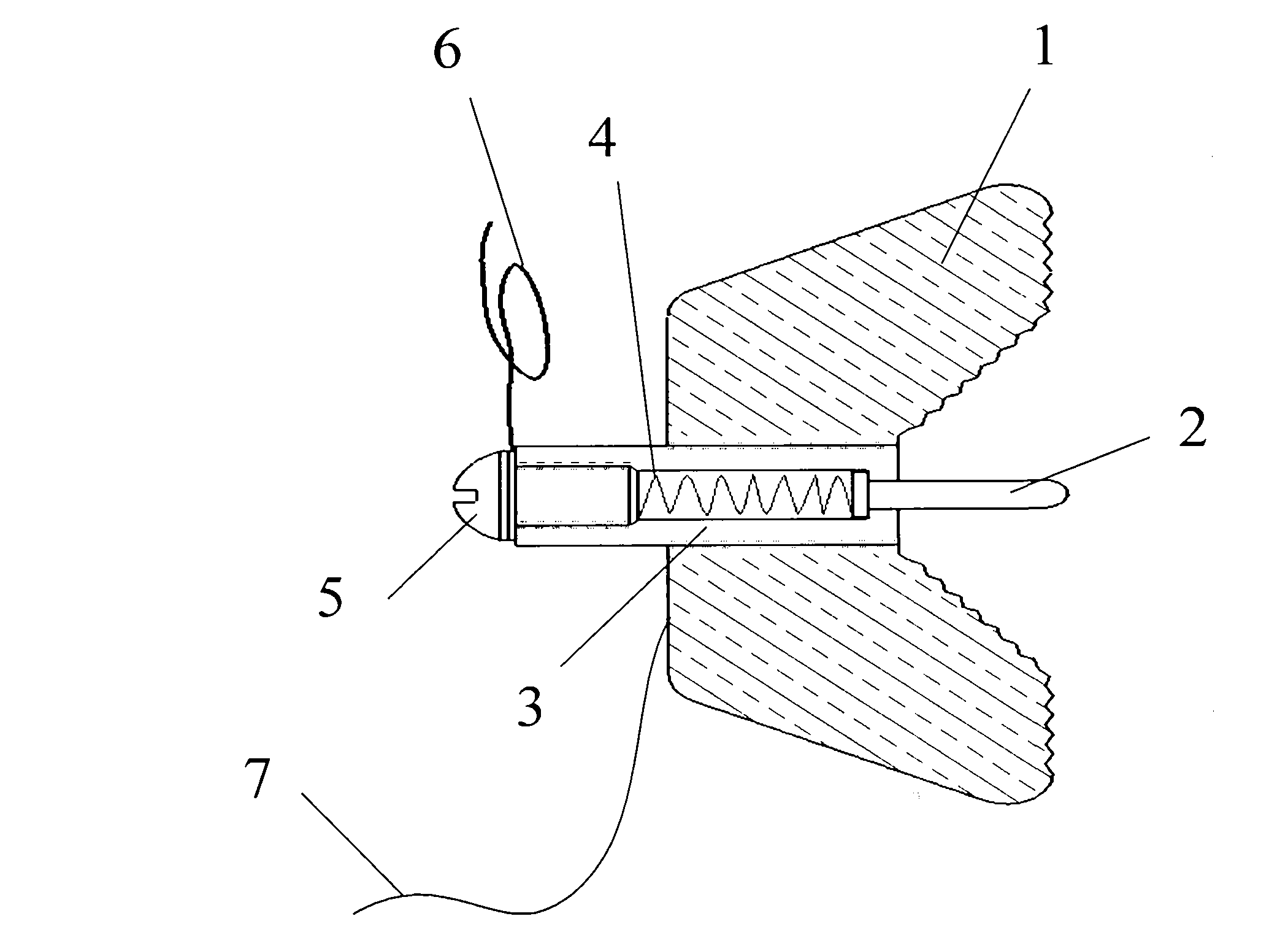

[0014] Such as figure 1 As a specific embodiment of the present invention, a current and voltage electrode includes a current electrode 1 and a voltage electrode 2. The voltage electrode 2 is a metal probe, one end of which leads to a voltage signal line terminal, and a voltage line 6 is drawn from the terminal. The current electrode 2 There is an insulating medium inside. In this embodiment, the insulating medium is made into an insulating ring 3, and the insulating ring 3 wraps the voltage electrode 2. The current electrode 1 is provided with a current wire lead-out terminal, and the terminal leads out a current wire 7.

[0015] The voltage electrode 2 is an elastic stretchable structure, which is used to tightly structure the test point when the voltage signal is taken at the test point of the tested product. In this embodiment, the elastic telescopic structure is a conductive elastic member 4, such as figure 1 As shown, one end of the conductive elastic member 4 is in con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com