Oil cylinder

A technology of oil cylinders and oil seals, which is applied in the direction of fluid pressure actuation devices, etc., can solve the problems of easy leakage in the sealing part, hinder the smooth progress of production, and unstable product quality, so as to ensure long-term normal operation, wide range of use, and excellent structure simple effect

Inactive Publication Date: 2011-06-29

SUZHOU DONON CARBON PRODS

View PDF7 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing oil cylinder with common structure, under the load of long-term uninterrupted operation, the sealing part is prone to leakage. If the leakage drops on the products and materials being processed, it will affect its original performance and cause poor product quality. Stable, low yield, hindering the smooth progress of production

In addition, due to the structural characteristics of the original oil cylinder, it is inconvenient to operate during maintenance, difficult to assemble, time-consuming to replace parts, and it is easy to cause deformation and damage of seals

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

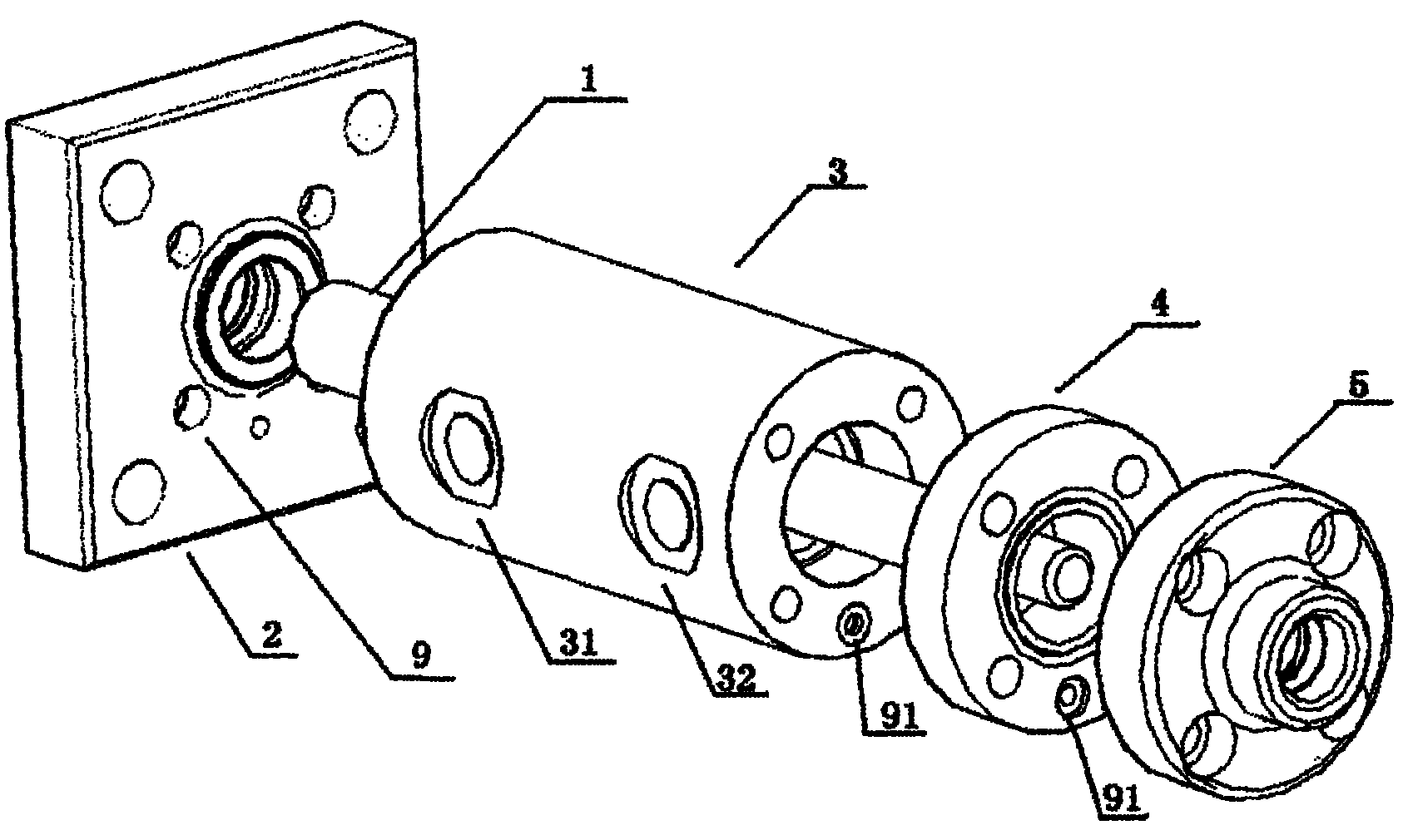

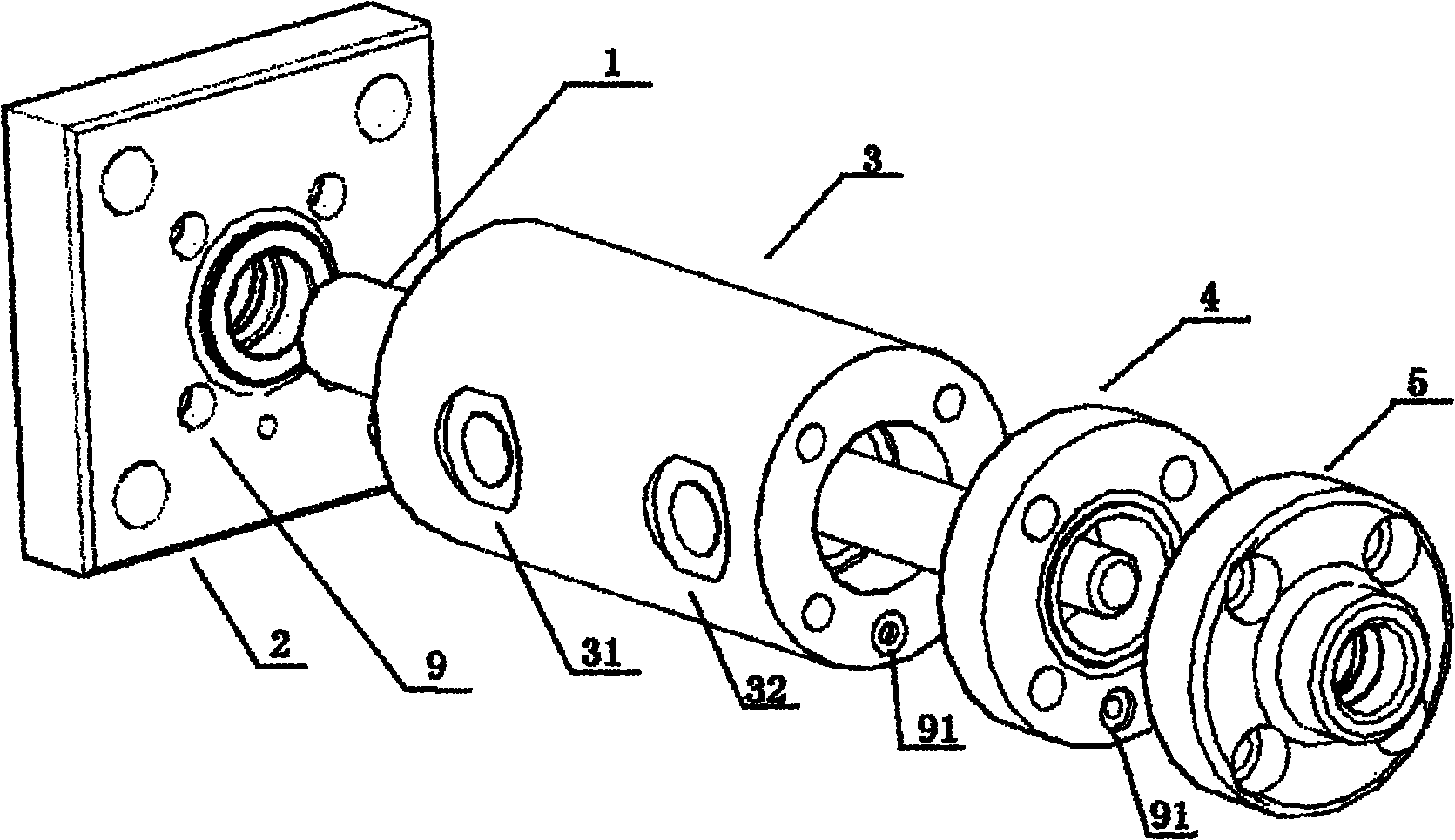

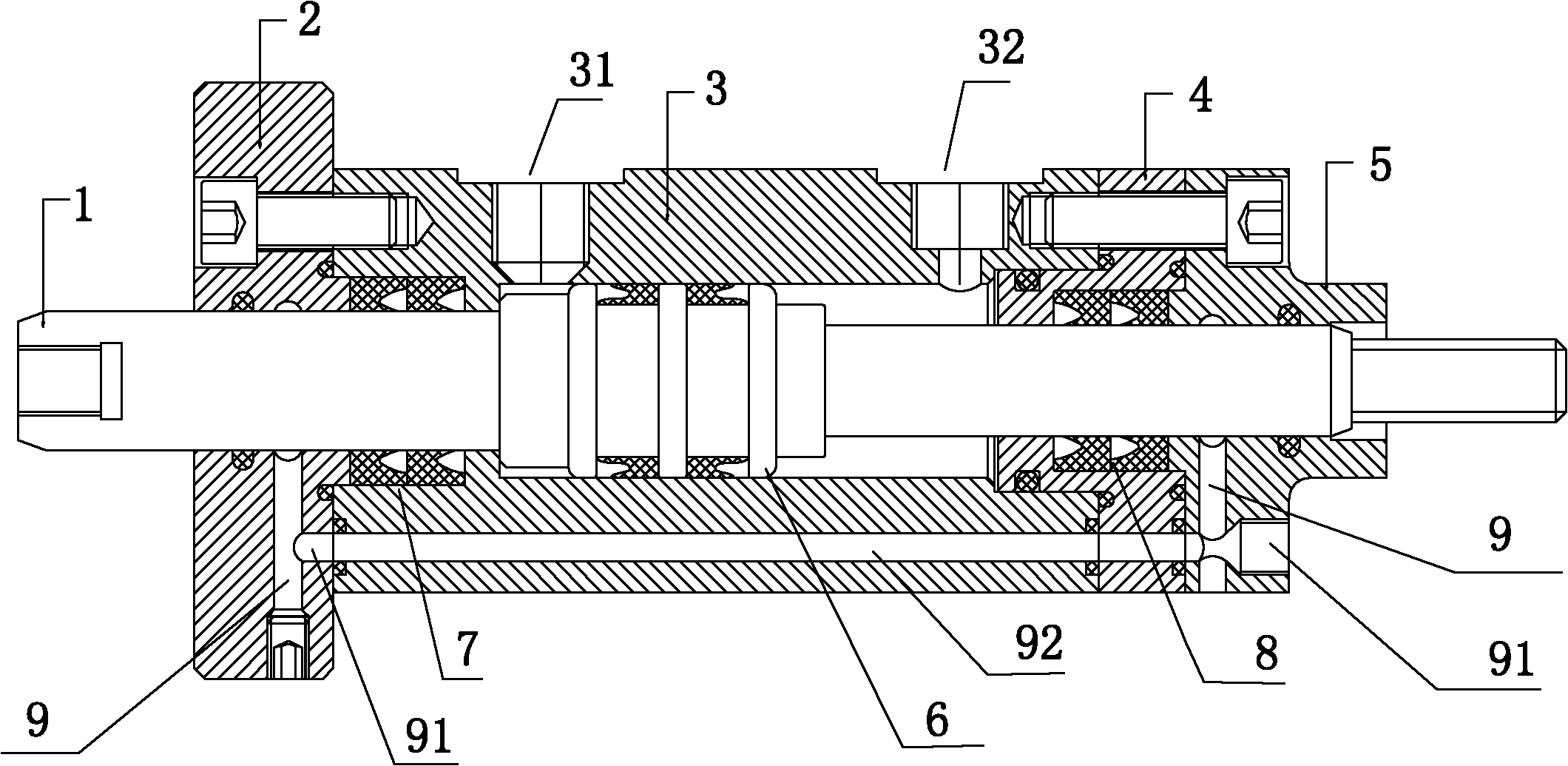

The invention discloses an oil cylinder, which includes a piston shaft, a front flange, a cylinder body, a locating sleeve, and a rear flange, wherein the front flange, the cylinder body, the locating sleeve, and the rear flange are sequentially arranged on the piston shaft in a penetrating way, and are matched and connected with each other; and a piston, which can perform reciprocating movement, is arranged in the cylinder body, and an oil inlet port and an oil outlet port are arranged on the cylinder body. By adopting the oil cylinder provided by the invention, a product and discharging oil are completely separated, the oil leakage cannot happen, the service life of the oil cylinder is prolonged, a series of problems caused by the oil leakage are solved, the finished product ratio is improved, the quality of the product is ensured, and the waste of material and the maintenance cost of the equipment are reduced; because an oil discharging channel is arranged, when a sealing part is under limiting wear, oil tightness of a shaft end can be guaranteed; the excess oil discharges from the oil discharging channel designed, so as to play a role of early warning; the oil cylinder has the advantages of simple structure, convenience in assembly, and firm combination among each component, and can ensure the machine to operate normally for a long term with small failure rate; and the oil cylinder has small and aesthetic appearance, and wide application range, and can replace the ordinary oil cylinder to use in various industries in the mechanical field.

Description

a cylinder technical field The invention relates to an oil cylinder for an oil hydraulic press. Background technique The existing oil cylinder with common structure, under the load of long-term uninterrupted operation, the sealing part is prone to leakage. If the leakage drops on the products and materials being processed, it will affect its original performance and cause poor product quality. Stability and low yield rate hinder the smooth progress of production. In addition, due to the structural characteristics of the original oil cylinder, it is inconvenient to operate during maintenance, difficult to assemble, time-consuming to replace parts, and it is easy to cause deformation and damage of the seal. Contents of the invention Purpose of the invention: In order to solve the deficiencies of the prior art, the present invention provides an oil cylinder with simple structure, long service life and no leakage. Technical solution: In order to achieve the above objecti...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F15B15/08

Inventor 陈卡苏

Owner SUZHOU DONON CARBON PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com