Impregnating and glue squeezing device

A glue stick and squeegee technology, which is applied to paper and other directions, can solve the problems of uneven, complex and patterned paper surface, and achieve the effects of uniform gluing, high measurement accuracy, and simple opening and closing operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following is a detailed description of the technical solutions of the present invention through the accompanying drawings.

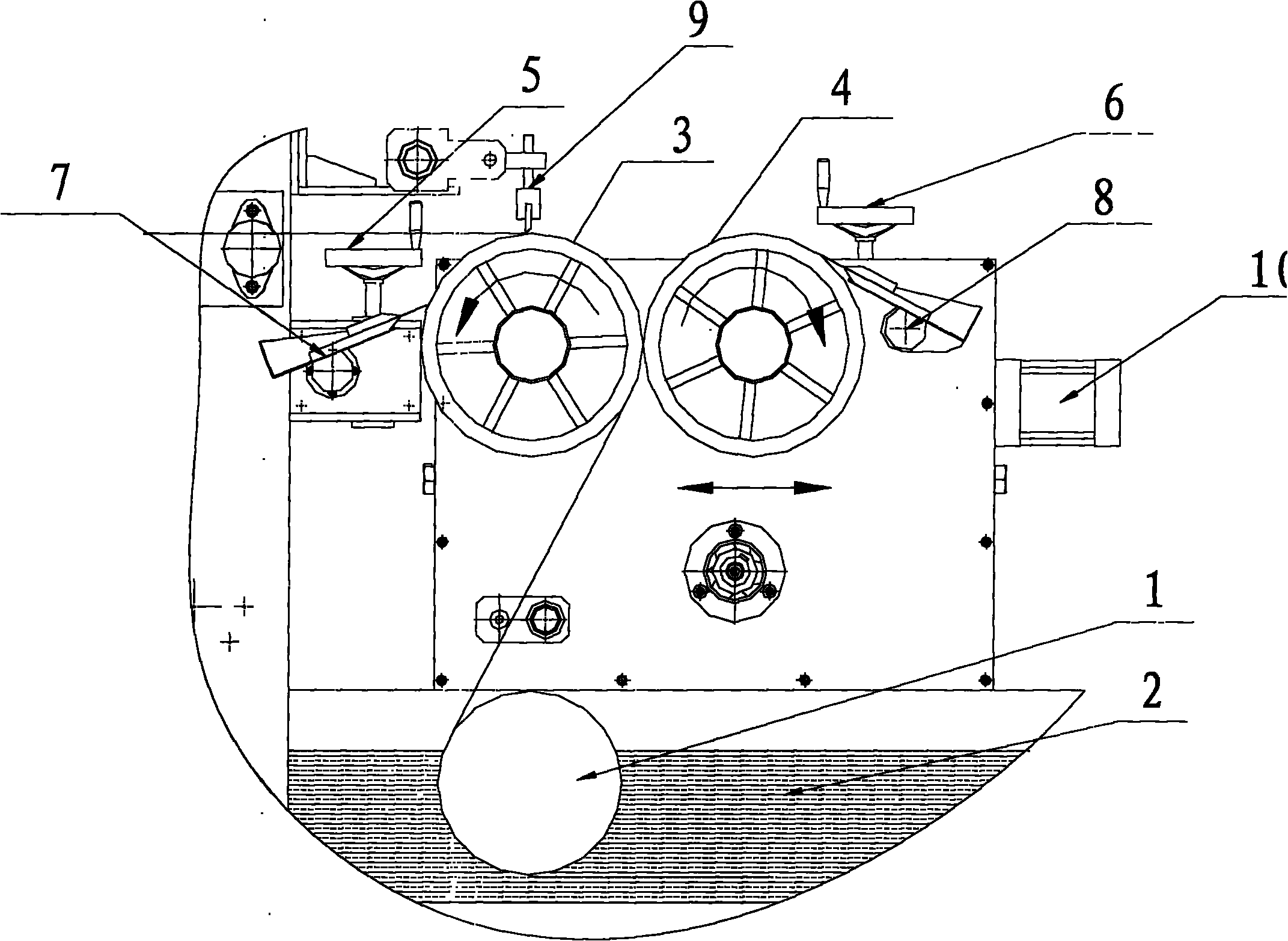

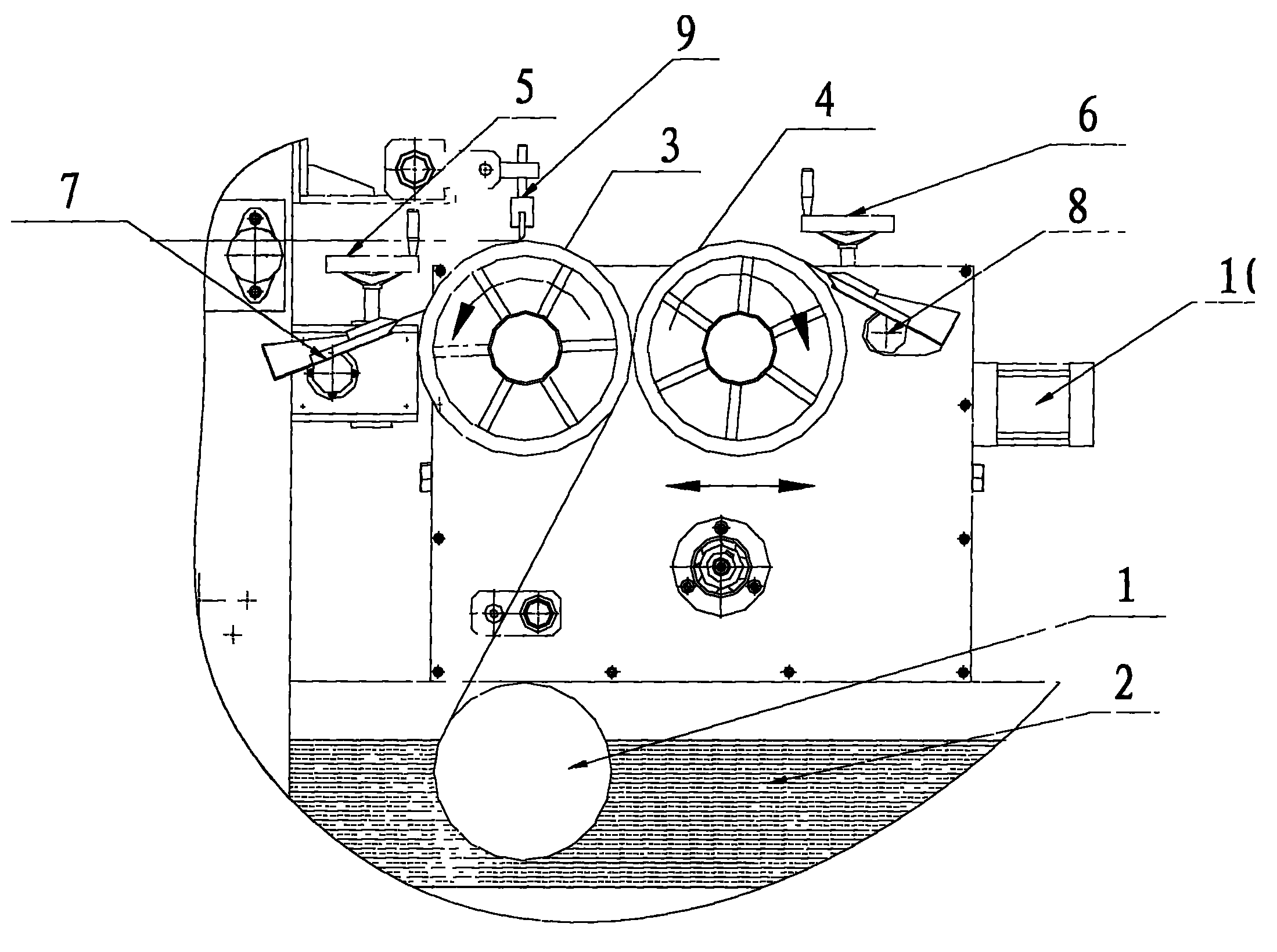

[0018] Such as figure 1 As shown in and 2, a dipping and extruding device according to the present invention includes a dipping stick 1, which is fixedly installed in the glue tank 2, and the impregnated paper is directly impregnated in the glue tank 2, bypassing the dipping stick 1, so that the dipping paper is impregnated completely. Also have the same diameter and synchronously rotate the extruding stick one 3 and the extruding stick two 4, the described extruding stick one 3 and the extruding stick two 4 are respectively connected with the cylinder and are positioned on the linear guide rail, and the two extruding sticks 3, There is a certain distance between 4, and the two extruding sticks 3, 4 are driven by the same motor 10, and the cylinder acts as the actuator, which can be opened and closed conveniently. In the working state, the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com