Cam for driving knitting needle and weft knitting machine

A flat knitting machine and triangular technology, applied in the direction of weft knitting, knitting, textile and paper making, etc., to achieve the effect of full contact depth and ensure contact depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

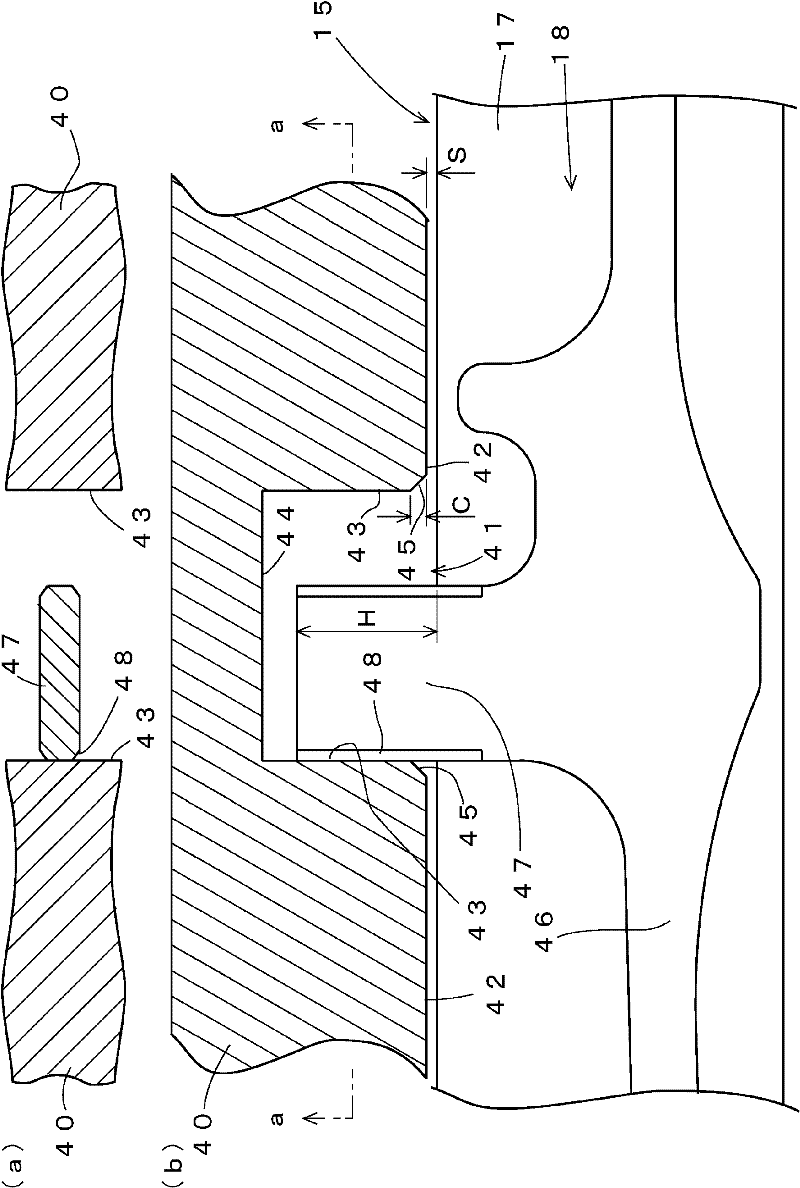

[0063] figure 1 (a) and figure 1 (b) shows the main part of the triangular member 40 which becomes one Embodiment of this invention as a simplified cross-sectional structure. in particular figure 1 (a) means from figure 1 (b) The section seen from section line a-a. In addition, in the following description, the part corresponding to the part demonstrated previously is denoted by the same reference symbol, and the overlapping description may be abbreviate|omitted.

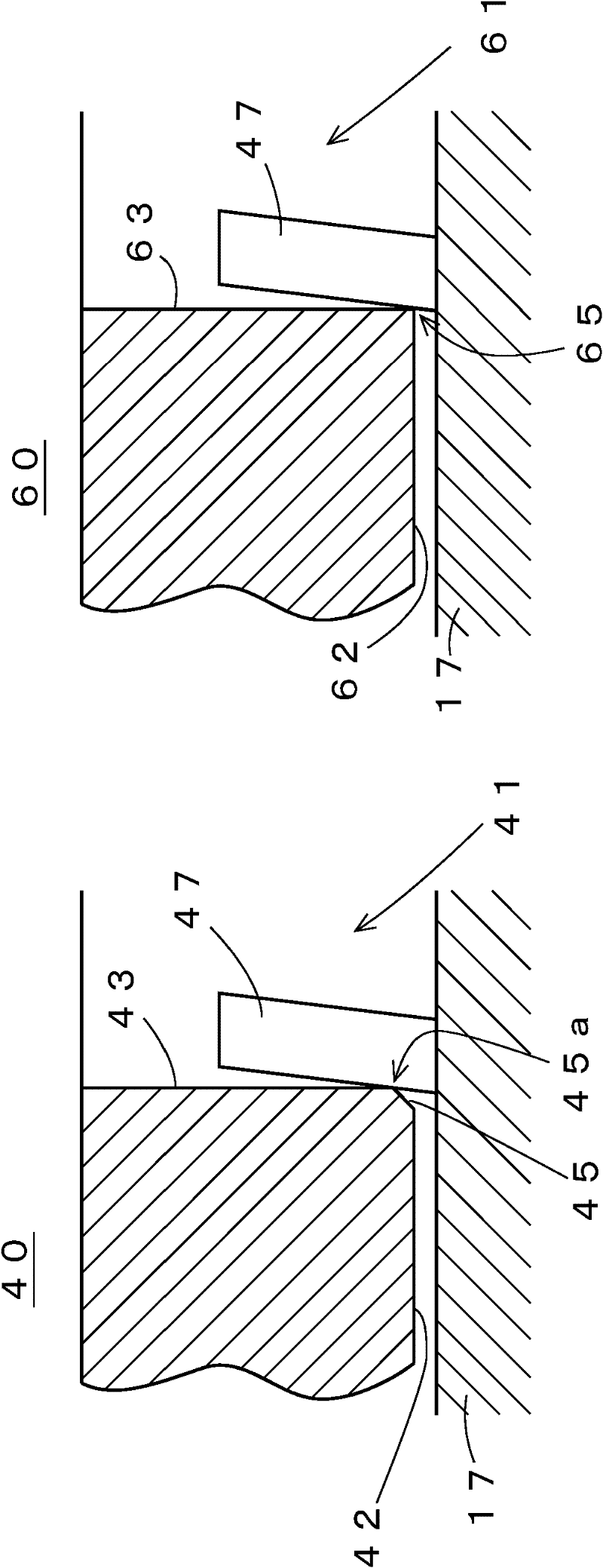

[0064] triangle member 40, for example with the Figure 7 The movable needle raising cam 23 used in the cam system 20 has the grooved cam 37 as well as the grooved cam 41 . The cam member 40 is substantially plate-shaped, and is mounted on a bottom plate on the bottom side of the carriage of the flat knitting machine. The cam surface 42 of the cam member 40 faces the surface of the needle bed 15 with a gap S when the cam member 40 is mounted on the carriage. The gap S is, for example, 0.2 mm. The groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com