High-speed heavy-duty linear reciprocating body operation energy storage device

A technology of rectilinear reciprocating motion and energy storage device, applied in the direction of machinery and equipment, can solve the problems of large power consumption, slow movement speed, damaged oil quality, etc., and achieve high work efficiency, fast liquid speed and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

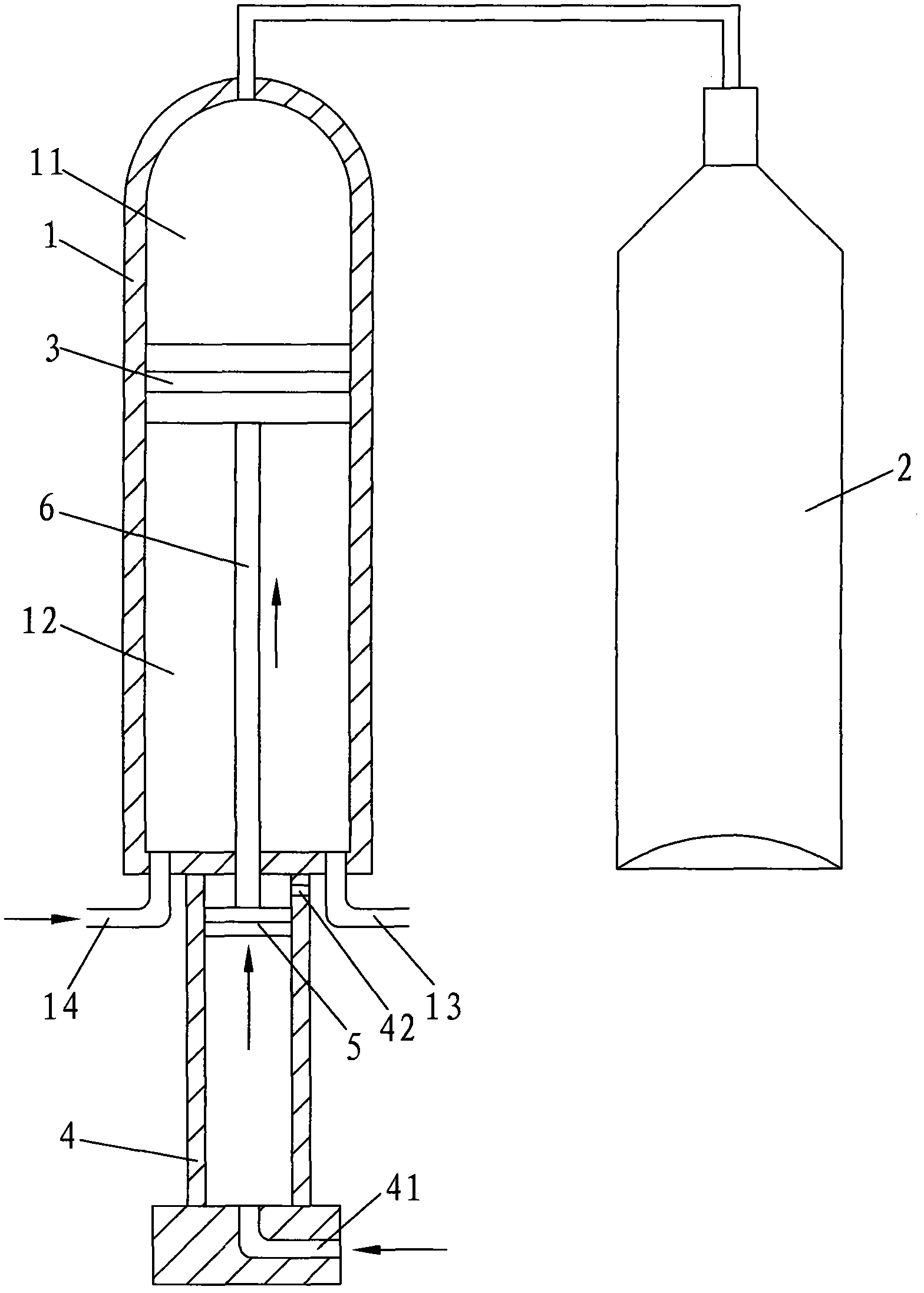

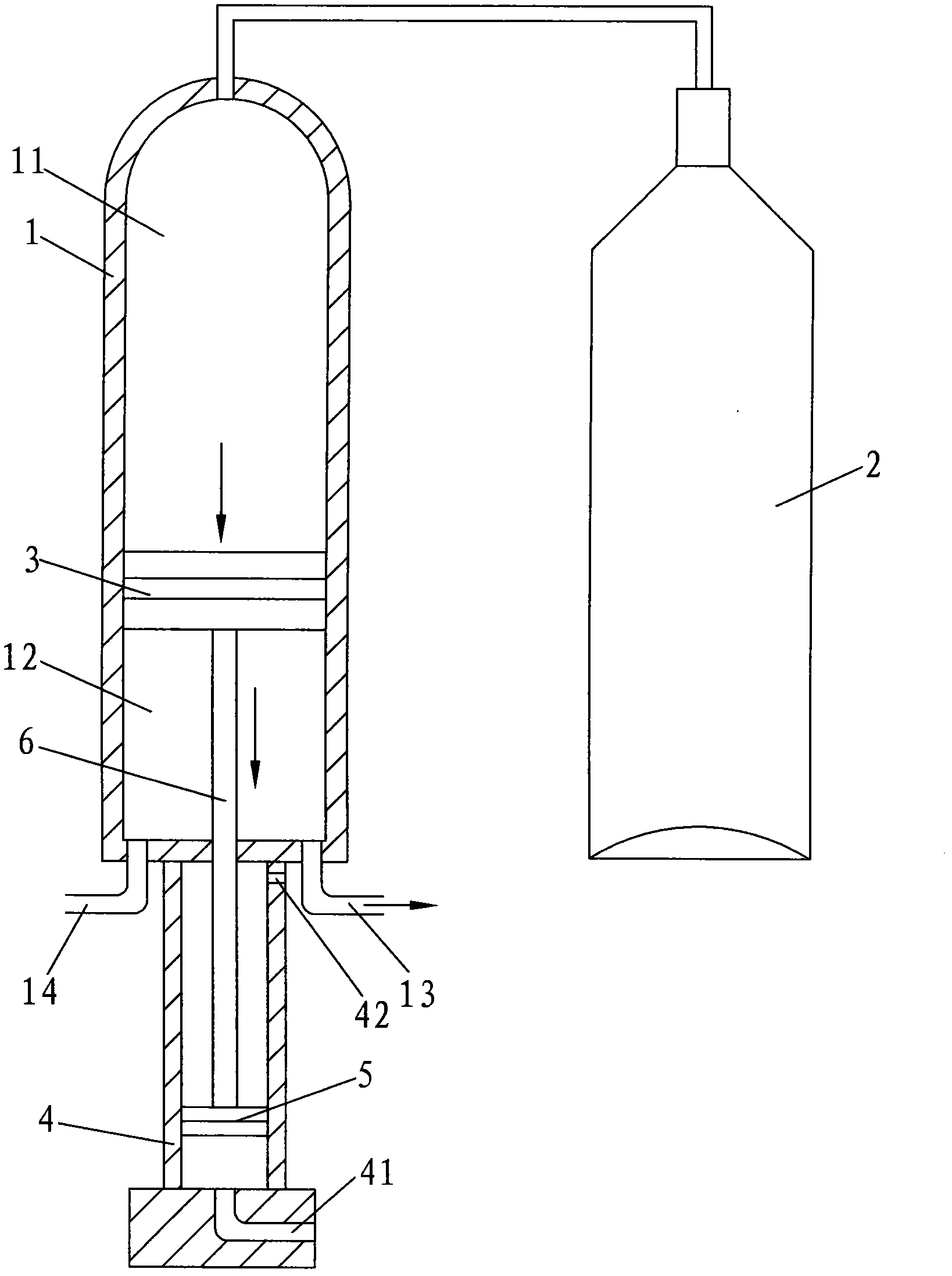

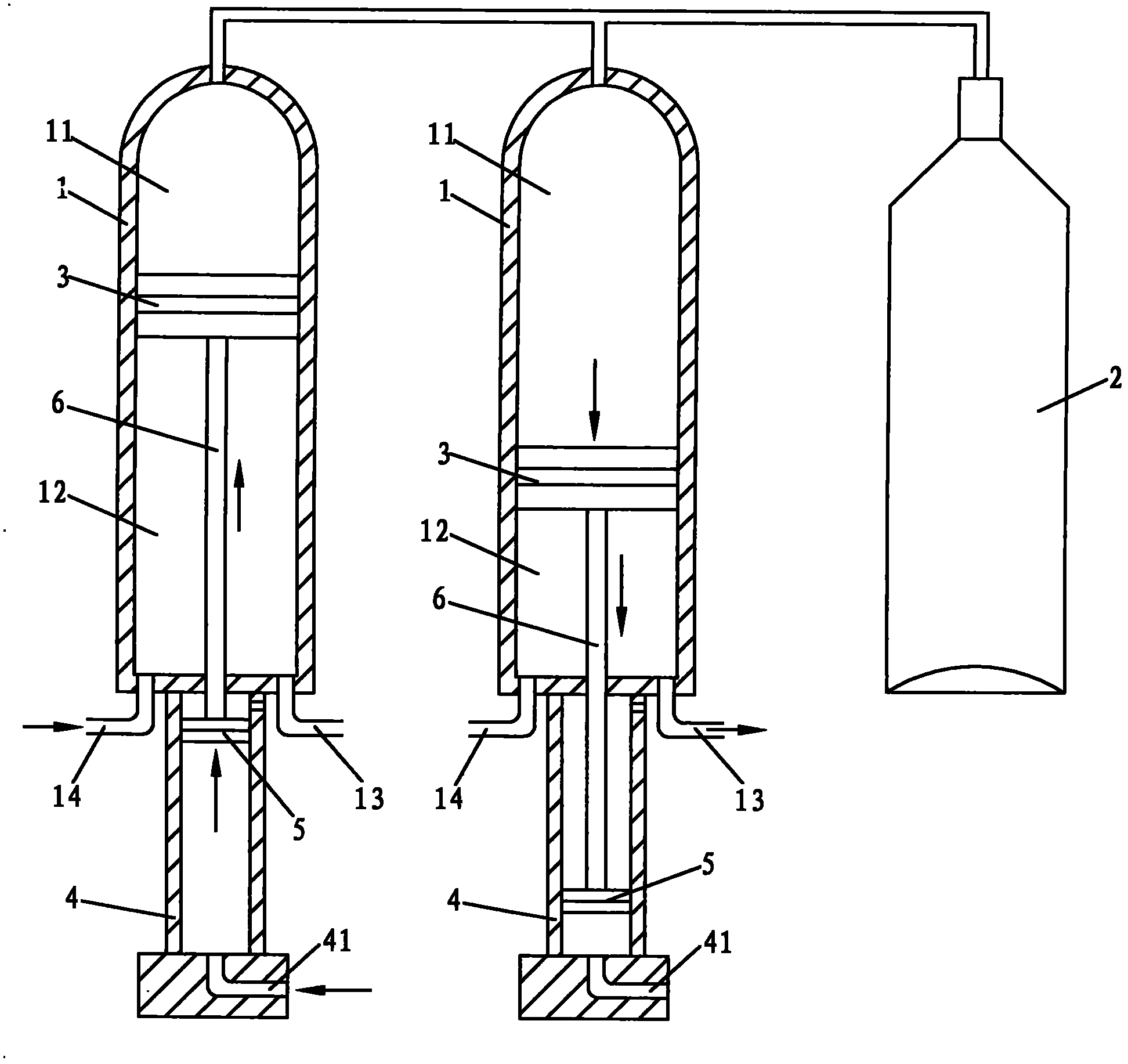

[0019] The present invention will be further explained below in conjunction with the drawings, see figure 1 , 2 , High-speed and heavy-duty linear reciprocating motion energy storage device, which includes a closed tank 1 and a gas storage tank 2. The tank 1 is equipped with a pneumatic piston 3, which separates the inner cavity of the tank 1 into a pneumatic chamber 11 and the liquid storage chamber 12, the gas storage tank 2 is connected with the air pressure chamber 11 through a pipe. The liquid storage chamber 12 is provided with a liquid discharge port 13 for outputting high-pressure liquid to the two hydraulic chambers of the working moving body, and recovering the hydraulic pressure of the working moving body. The liquid return port 14 for the liquid, the tank 1 is provided with a high-pressure hydraulic cylinder 4, one end of the high-pressure hydraulic cylinder 4 is connected to the tank 1 at a position corresponding to the liquid storage chamber 12, and the other end is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com