Chemically mechanical polishing slurry

A chemical mechanical and polishing liquid technology, which is applied in the manufacture of polishing compositions containing abrasives, electrical components, semiconductors/solid-state devices, etc., can solve problems such as pitting corrosion, large metal surface damage, and surface roughness, so as to prevent the overall and local corrosion, increase the level of planarization, and improve the effect of surface quality

Active Publication Date: 2011-06-22

ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

View PDF2 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In typical chemical mechanical polishing of metals, defect levels are often high, especially if pitting, edge erosion, corrosion, etc. are present

Moreover, the polishing rate is also high, and the damage to the metal surface is relatively large, and problems such as scratches and rough surfaces are prone to occur.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~30

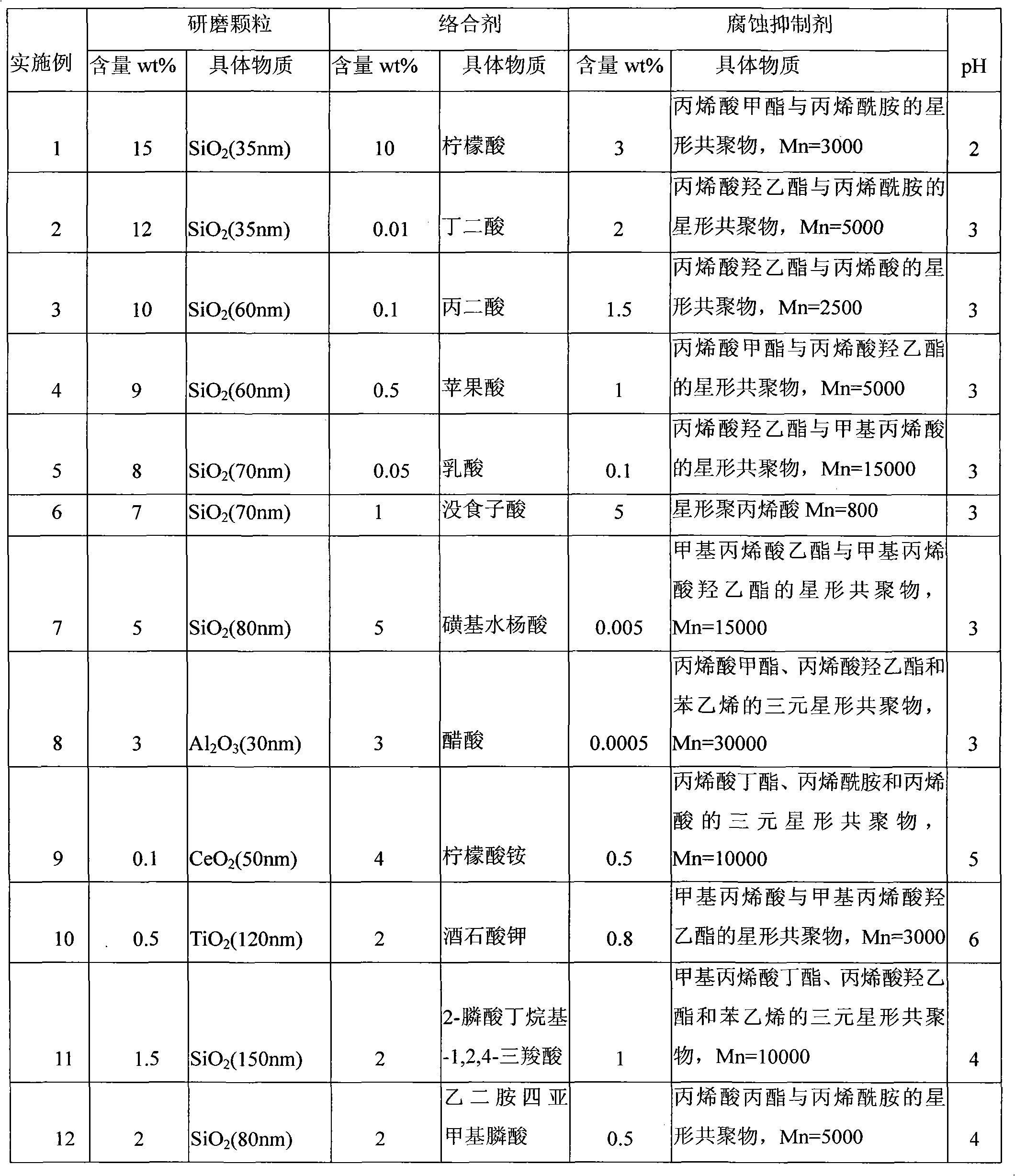

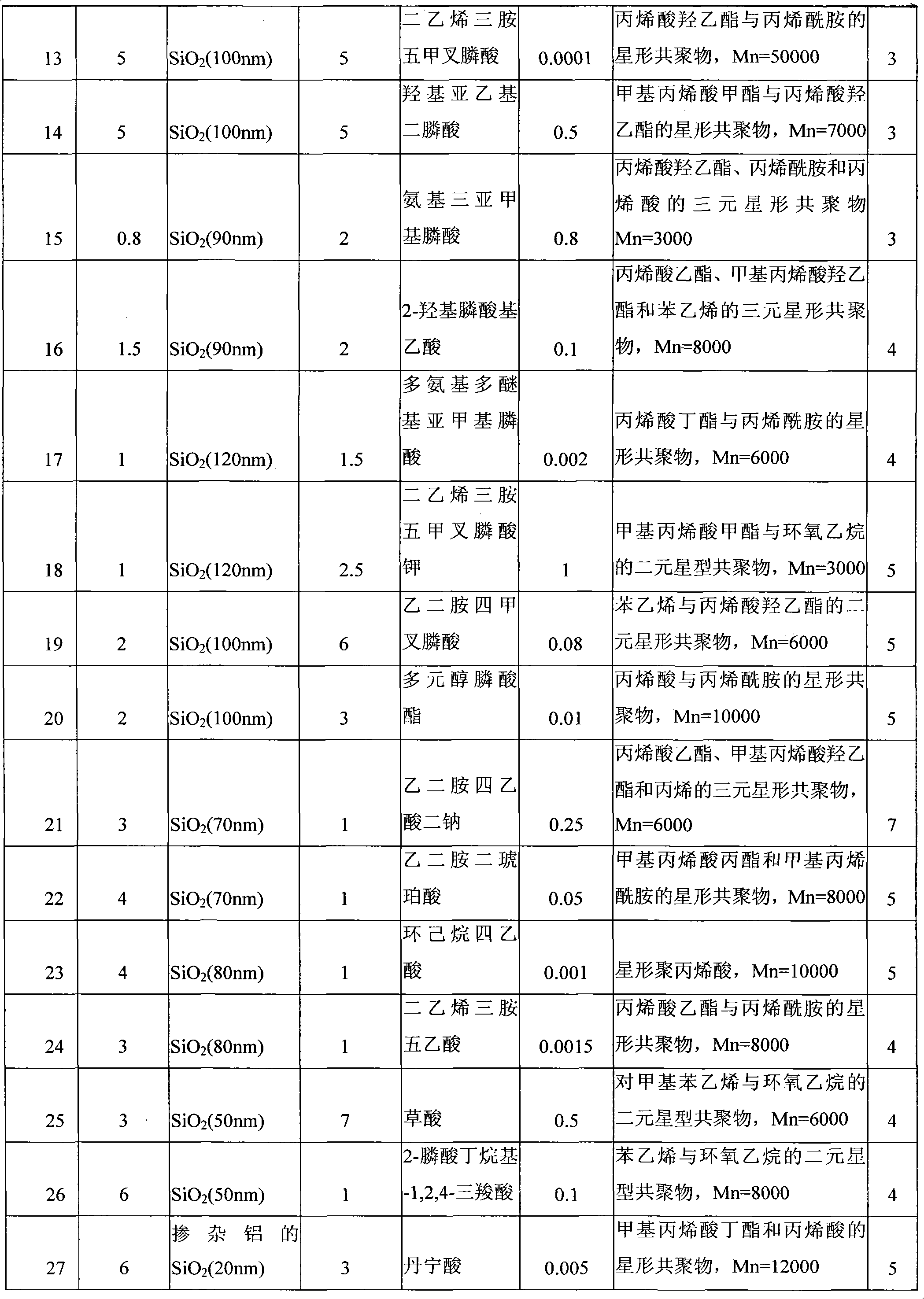

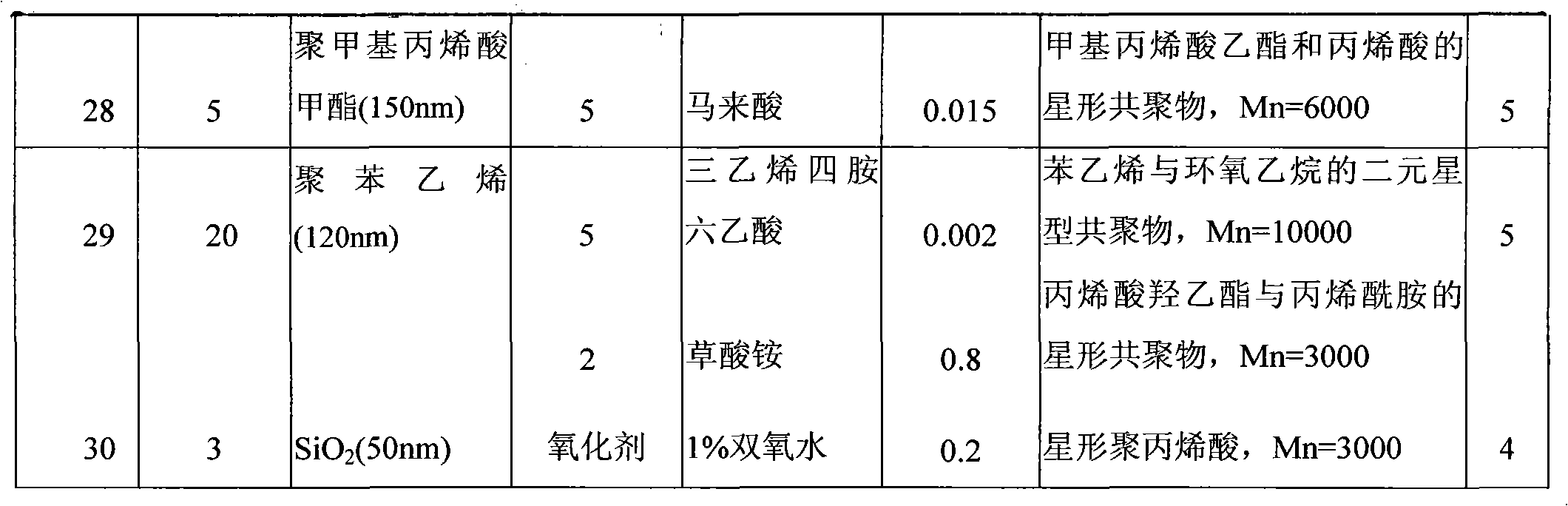

[0026] Table 1 shows Examples 1-30 of the chemical mechanical polishing solution of the present invention. According to the formula given in the table, all components are mixed evenly, and the mass percentage is made up to 100% with water. with KOH or HNO 3 Adjust to desired pH.

[0027] Table 1 Examples 1-30

[0028]

[0029]

[0030]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses new chemically mechanical polishing slurry for polishing metals. The polishing slurry is prepared by combining the following substances: abrasive particles, complexing agents and corrosion inhibitors. The slurry has the following positive effects: the removal rate of metals can be reduced, the metal materials can be prevented from whole and local corrosion, the defects can be obviously decreased and the surface quality can be improved.

Description

technical field [0001] The invention relates to a chemical mechanical polishing fluid. Background technique [0002] With the development of microelectronics technology, the integration level of very large scale integrated circuit chips has reached billions of components, and the feature size has entered the nanometer level, which requires nearly a hundred processes in the microelectronics process, especially multi-layer wiring, lining The bottom and medium must be chemically mechanically globally planarized, and chemical mechanical polishing (CMP) has been proven to be the best planarization method. [0003] In chemical mechanical polishing methods, the polished surface of a substrate is brought into direct contact with a rotating polishing pad while pressure is applied to the backside of the substrate. During polishing, the polishing pad rotates with the operating table while maintaining a downward force on the back of the substrate, and a liquid composed of abrasives and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09G1/02C23F3/03

CPCH01L21/3212C09G1/02

Inventor 荆建芬蔡鑫元

Owner ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com