Recovery method of monochloro methane

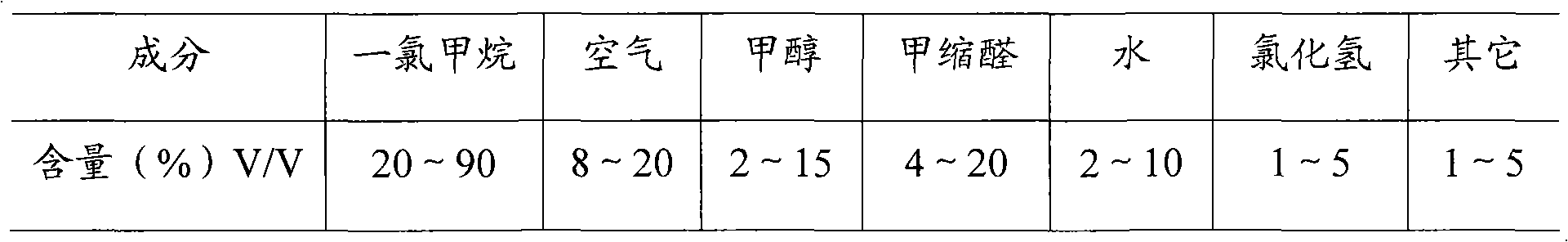

A recovery method, a technology of monochloromethane, applied in chemical instruments and methods, halogenated hydrocarbon preparation, organic chemistry, etc., can solve the problem of short, usually several seconds to several minutes, the adsorbent cannot be reused, and does not have the conditions for industrialization. and other problems, to reduce the pressure of environmental protection, avoid production and discharge treatment problems, and achieve good purging effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The monochloromethane-containing tail gas produced by the glycine method to prepare glyphosate acid is washed by multi-tower countercurrent water to remove most of the methanol and methylal in the gas. The temperature of the washing water is controlled at 5°C and the circulation flow rate is 40m 3 / h, and then through the alkali washing tower, the circulation flow of liquid alkali is 20m 3 / h, remove the acid gas in the tail gas, the monochloromethane gas from the acid gas is firstly pressurized by the fan to about 25KPa, and then enters the molecular sieve adsorption tower from top to bottom, the adsorption temperature is controlled at 25 ℃, and it is discharged from the bottom of the adsorption tower The monochloromethane gas from which impurities have been removed is obtained at the outlet, and its moisture content is 35ppm. Use nitrogen as the regeneration gas to heat it to 250°C and enter the adsorption tower from the bottom to regenerate it. After the adsorbate is ...

Embodiment 2

[0037] The monochloromethane-containing tail gas produced by the glycine method to prepare glyphosate acid is washed with countercurrent water in three towers to remove most of the methanol and methylal in the gas. The temperature of the washing water is controlled at 50°C and the circulation flow is 10m 3 / h, and then through the alkali washing tower, the circulation flow of liquid alkali is 5m 3 / h, to remove the acid gas in the tail gas, the monochloromethane gas to remove the acid gas is first pressurized by a fan to about 20KPa, then passed through a cold dryer, cooled to 10°C, and free water is discharged, from top to bottom Enter the molecular sieve adsorption tower, control the adsorption temperature to 50°C, obtain the impurity-removed monochloromethane gas from the lower outlet of the adsorption tower, and its moisture content is 25ppm, use the raw material gas as the regeneration gas to heat to 200°C and enter the adsorption tower from the bottom, about Change to nit...

Embodiment 3

[0039] The monochloromethane-containing tail gas produced by the glycine method to prepare glyphosate acid is washed with countercurrent water in three towers to remove most of the methanol and methylal in the gas. The temperature of the washing water is controlled at 30°C and the circulation flow is 20m 3 / h, then through the alkali washing tower, the circulation flow of liquid alkali is 14m 3 / h, to remove the acid gas in the tail gas, the monochloromethane gas to remove the acid gas is first pressurized by the fan to about 25KPa, first passed through the cold dryer, cooled to 10°C, and free water is discharged, from top to bottom Enter the molecular sieve adsorption tower, control the adsorption temperature to 38°C, obtain the impurity-removed monochloromethane gas from the lower outlet of the adsorption tower, and its moisture content is 25ppm, use the raw material gas as the regeneration gas to heat to 210°C and enter the adsorption tower from the bottom, about Change to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com