Construction technology of relay jacking for glass fiber reinforced plastics sand-inclusion pipe-jacking and apparatus thereof

A glass fiber reinforced plastic sand inclusion and construction technology technology, which is applied in water supply devices, pipes/pipe joints/pipes, sewer systems, etc., can solve the problems of water flow, construction difficulties, sudden changes in pipe diameter, etc., to save construction costs and improve one-time The effect of jacking distance and force is reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

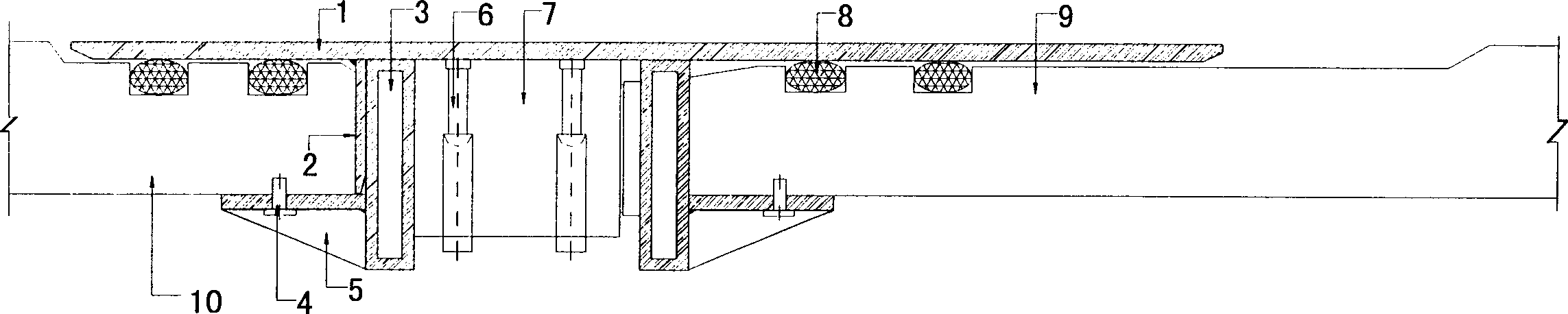

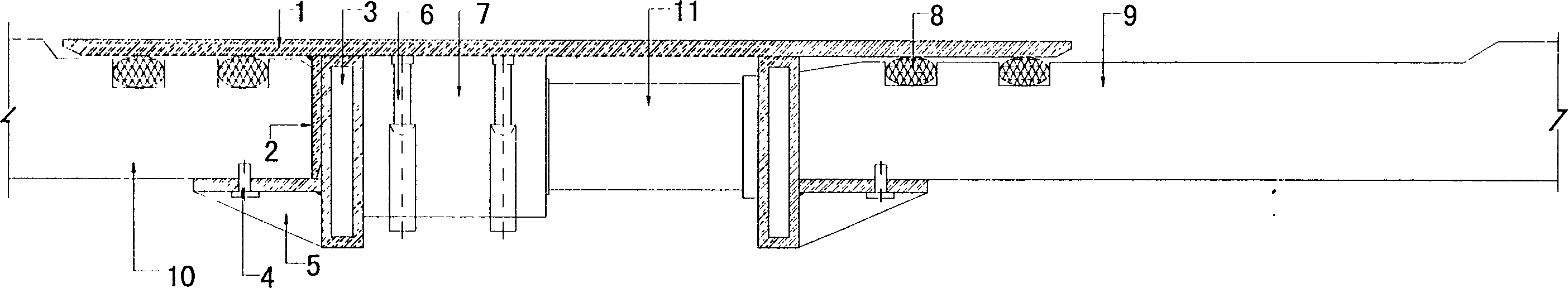

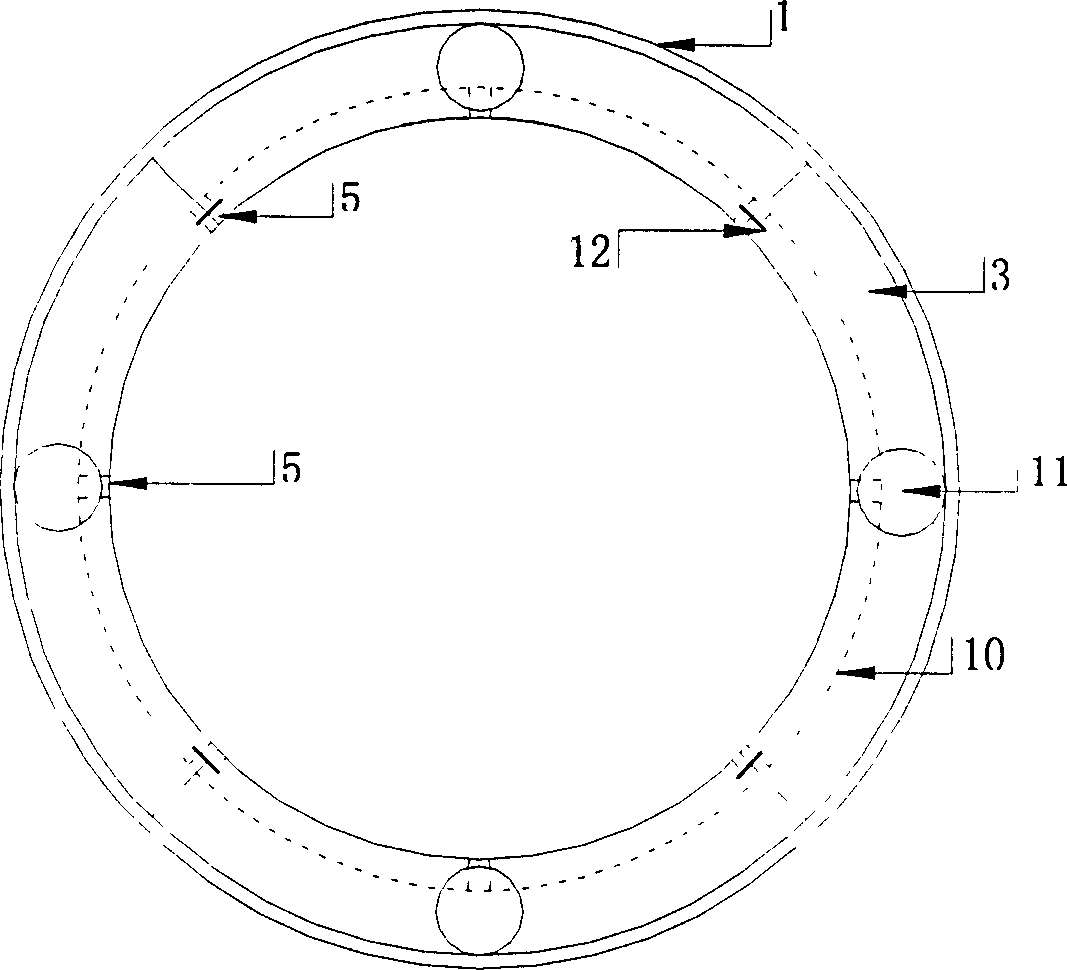

[0025]As shown in the figure, the FRP pipe jacking relay room device of the present invention has a relay room steel sleeve 1 connecting the front and rear pipe jacking, and the front and rear sections of the relay room steel sleeve 1 are respectively sleeved on the front glass fiber reinforced plastic tube. Two O-shaped rubber sealing rings 8 are respectively provided at the front and rear joints of the tail of the sand-filled pipe 10 and the head of the rear glass-steel sand-filled pipe 9 . Because the deflection correction of pipe jacking may cause a certain deflection angle at the pipe joint, when the groundwater level is high and the water pressure is high, if only a general steel collar or a rubber ring is used to prevent seepage, the effect is often not very good , Therefore, the use of this double O-shaped secondary sealing structure can ensure the anti-seepage effect. A steel backing plate 2 is closely attached to the tail end of the front glass fiber reinforced plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com