Electrode plate of light lead storage battery

A technology for lead-acid batteries and electrode plates, applied in the direction of electrode carriers/collectors, etc., can solve the problems of affecting the electric energy storage and power supply capacity of lead-acid batteries, the poor quality of lead-acid batteries, and the inapplicability of lead-acid batteries, so as to avoid the occurrence of lead smoke and improve Grade, weight reduction effect

Inactive Publication Date: 2011-06-15

章传宝

View PDF3 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For a long time, many people have plated lead on aluminum, plastic, copper and other materials, and then made grids. The purpose is to try to reduce the amount of lead used to reduce the weight of the battery. The grid made of aluminum or copper materials, Metal aluminum or metal copper will be corroded by the electro-liquid, which will lead to an increasing amount of impurities contained in the electro-liquid, which seriously affects the electric energy storage and power supply capacity of the lead-acid battery. However, due to the fact that the plastic substrate itself does not have conductivity, the quality of this lead-acid battery is very poor in actual use and cannot be applied

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

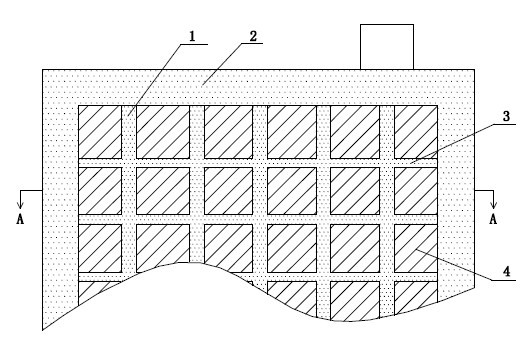

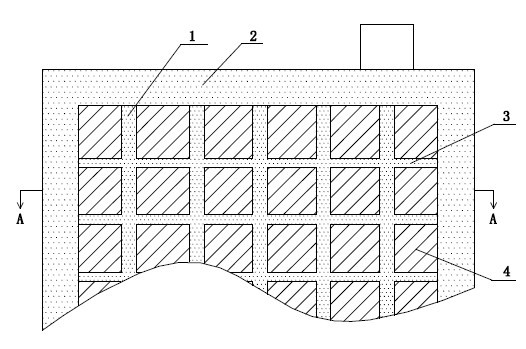

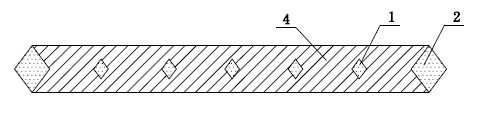

The invention relates to a storage battery, in particular to an electrode plate of a light lead storage battery. The electrode plate comprises a grid and active substance and is characterized in that the grid is made by pressing graphite material and the active substance is directly adhered on the surface of the grid. The graphite material is adopted to make the grid of the lead storage battery, the active substance is retained, and the weight of the lead storage battery is reduced; and the grid is made from the graphite instead of lead, thus lead fume in a lead grid casting process is avoided, lead consumption is saved by about 40%, the problem that short circuit is caused by growth of the grid in the use process of the battery can be solved to reduce fault, and the reliability is improved. In the invention, the grid does not adopt lead, thus not only is the storing capacity of the battery improved, but also the grade of the product is improved.

Description

Electrode plates for light lead storage batteries technical field The invention relates to a storage battery, in particular to an electrode plate of a light lead storage battery. Background technique The structure of the lead-acid battery is composed of positive and negative plates, bus bars, separators (membranes), electrolytes, exhaust valves, positive and negative poles, and shells (slots), while the positive and negative plates are composed of positive and negative grids. Composed of positive and negative active materials coated on it, the grid is made of lead, and then coated with lead paste on its surface, the weight of the lead-acid battery mainly comes from the plate, that is, the grid and the active material. For a long time, many people have plated lead on aluminum, plastic, copper and other materials, and then made grids. The purpose is to try to reduce the amount of lead used to reduce the weight of the battery. The grid made of aluminum or copper materials, M...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M4/68H01M4/73H01M4/74

CPCY02E60/12Y02E60/10

Inventor 章传宝

Owner 章传宝

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com