Polycarboxylic acid, use thereof and water reducer containing same

A polycarboxylic acid and water reducing agent technology, applied in the field of cement admixtures, can solve the problems of poor construction performance, poor slump retention, and reaction failure, and achieve strong steric hindrance, excellent slump retention, and good slump retention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

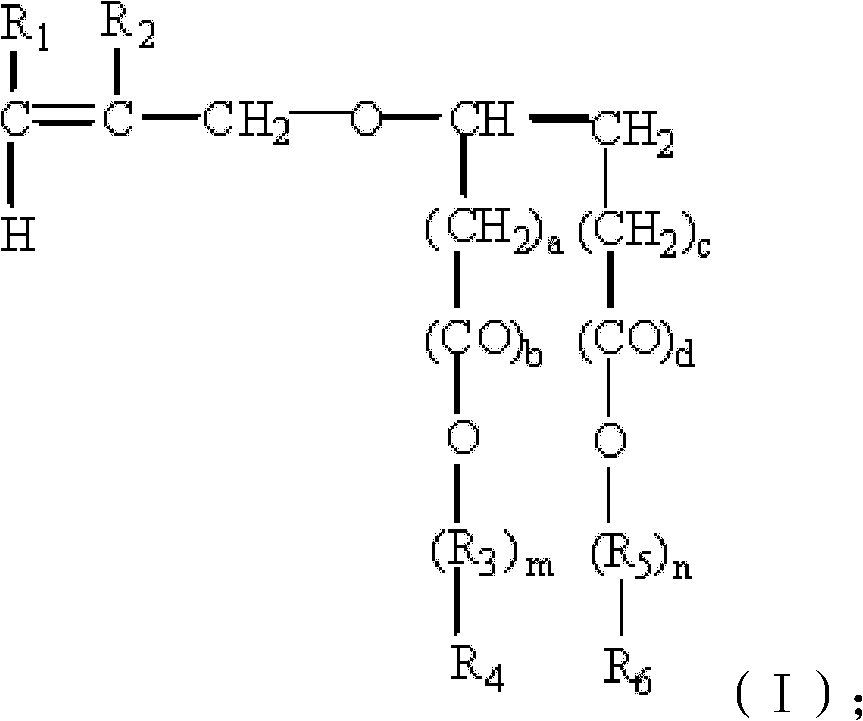

[0051] In the glass reaction equipment equipped with thermometer, stirrer, constant pressure dropping funnel, nitrogen conduit and reflux condenser, add 140 mass parts (accounting for 70wt% of all monomers) with the above-mentioned general formula (I) The unsaturated polyether of side chain, the mercaptoacetic acid of 2 mass parts and the water of 70 mass parts; R in the general formula (I) 1 , R 2 Both represent hydrogen atoms, R 3 , R 5 Both represent oxyethylene groups, R 4 stands for hydrogen atom, R 6 stands for C 1 Alkyl; a is 0, c is 3, b is 0, d is 1, m and n are both 13;

[0052] While stirring, purging the interior of the reaction equipment with nitrogen, when the temperature rises to 70°C, a solution of 60 parts by mass of acrylic acid (accounting for 30 wt% of all monomers) and 100 parts by mass of water is added dropwise to the reaction device at a uniform speed , the dropping time is 3 hours; Meanwhile, the solution of the ammonium persulfate of 4 mass part...

Embodiment 2

[0055] In the glass reaction equipment that thermometer, stirrer, constant pressure dropping funnel, nitrogen conduit and reflux condenser are equipped with, add 120 mass parts (79 accounts for the wt% of whole monomer) with the belt of above-mentioned general formula (I) The unsaturated polyether of double side chain, the mercaptoacetic acid of 1.9 mass parts and the water of 66.7 mass parts; R in the general formula (I) 1 , R 2 Both represent methyl, R 3 , R 5 Both represent oxypropylene groups, R 4 stands for C 20 the alkyl group, R 6 stands for C 18 The alkyl group; a is 3, c is 0, b is 1, d is 0, m is 48, n is 50;

[0056] While stirring, purging the inside of the reaction device with nitrogen, when the temperature rose to 70°C, 32 parts by mass of sodium methacrylate (accounting for 21 wt% of all monomers) and 80 parts by mass of sodium methacrylate were added dropwise to the reaction device at a uniform speed. The solution of water, the dropping time is 3 hours; ...

Embodiment 3

[0059] In the glass reaction equipment equipped with thermometer, stirrer, constant pressure dropping funnel, nitrogen conduit and reflux condenser, add 100 mass parts (accounting for 50wt% of all monomers) with the above-mentioned general formula (I) The unsaturated polyether of side chain, the mercaptoacetic acid of 1.60 mass parts and the water of 61.4 mass parts; R in the general formula (I) 1 Represents methyl, R 2 represents a hydrogen atom, (R 3 ) m , (R 5 ) n Both represent groups composed of oxyethylene and oxypropylene groups in a random copolymerization manner, R 4 stands for C 1 the alkyl group, R 6 Represents a hydrogen atom; a is 2, c is 1, b and d are both 1, m and n are both 20;

[0060] While stirring, purging the inside of the reaction device with nitrogen, when the temperature rose to 70°C, in the reaction device, dropwise added maleic anhydride by 50 parts by mass (accounting for 25wt% of all monomers), 50 parts by mass of Sodium methacryl sulfonate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com