Purification method of steviolbioside (STB)

A technology of stevioside and purification method, which is applied in the field of purification of stevioside STB, and can solve problems such as no STB purification method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

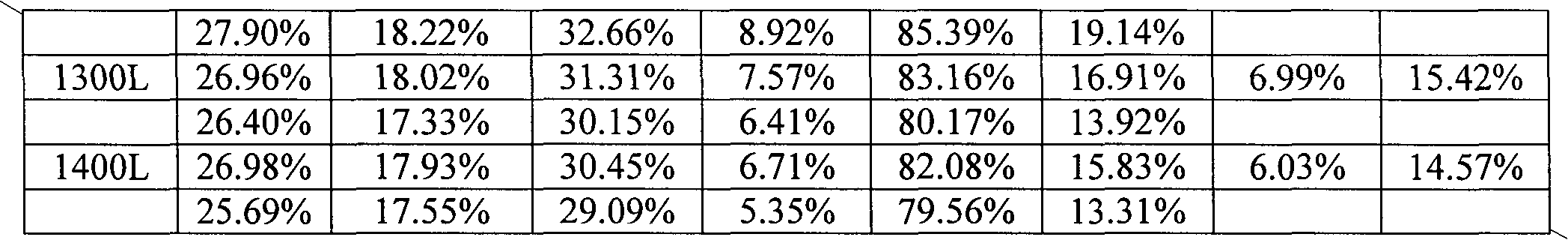

[0028] Example 1: Take mother liquid sugar, analyze the content of STB by liquid chromatography to be 23.74%, make the mother liquid sugar into a feed liquid with a concentration of 30mg / ml, take 1400L of the feed liquid, and use a slow flow rate of 1.5L / min Flow through the 500L DA-201-L resin column produced by Jiangsu Suqing Water Treatment Company. During the process of the material liquid flowing through the resin column, the resin column selectively adsorbs the material liquid according to the polarity of different components of steviol glycosides. The pH of the adsorption environment is 5.5. After 15 hours, the adsorption of the material solution is completed, and the steviol glycosides adsorbed on the resin are analyzed with 1400L of 70% ethanol. The eluent was cut in sections with 100L as the unit, and the content of STB was detected by liquid chromatography analysis. It was found that steviol glycosides RB began to be eluted in large quantities at 800L of the eluent. ...

Embodiment 2

[0036] Example 2: Take 20 kg of crude steviol glycosides with 48.86% of STB prepared in Example 1 and 30 kg of ethanol with a concentration of 88% and 37% methanol in a 1:3 ratio. After the dissolution is completed at 65℃, the temperature will drop to room temperature rapidly within 5 minutes. The mixture is stirred for 3 minutes every 4 hours. After leaving for 48 hours, the dissolved mixture is separated into solid and liquid, and the filtered solid is added with no brine to adjust the concentration. Concentrate to 27% and concentrate to 43%. The solution is dried to obtain 6.2 kg of refined steviol glycosides. The content of steviol glycosides in the refined stevioside is 95.73%; the liquid obtained by solid-liquid separation is evaporated to remove ethanol and excess water, The concentration of the aqueous solution of steviol glycosides was adjusted to 47%, and 11 kg of refined steviol glycosides were obtained after drying. The total recovery rate of steviol glycosides was 8...

Embodiment 3

[0037] Example 3: A mixed solvent of 20 kg of crude steviol glycosides with 48.86% of STB content prepared in Example 1 mixed with 32 kg of 90% ethanol and 35% methanol in a ratio of 1:3 After the dissolution is completed at 67℃, the temperature will drop to room temperature rapidly within 7 minutes, and the mixture will be stirred for 5 minutes every 5 hours. After standing for 60 hours, the dissolved mixture will undergo solid-liquid separation through a plate and frame filter press, and the filtered solid Add no salt water to adjust the concentration to 25%, concentrate to 45%, and dry the solution to obtain 6.4 kg of refined stevioside. The content of stevioside STB in the refined stevioside is 95.34%; the liquid obtained by solid-liquid separation is evaporated. The concentration of the aqueous solution of steviol glycosides was adjusted to 45% with ethanol and excess water, and 11.5 kg of refined steviol glycosides were obtained after drying. The total recovery rate of ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com