Preparation method of 3-(2,2,2-trimethylhydrazine)propionate dihydrate

A technology of trimethylhydrazine and dihydration, applied in the field of preparation of dihydrate 3-propionate, can solve the problems of long filling process, difficult removal, low efficiency, etc., and achieve the effect of less dosage and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

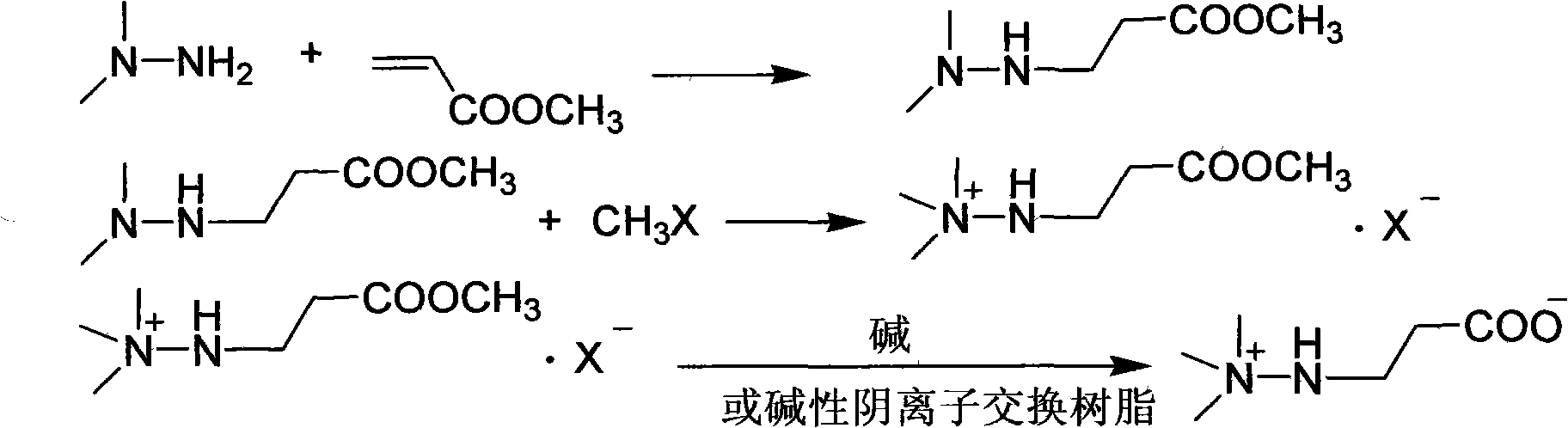

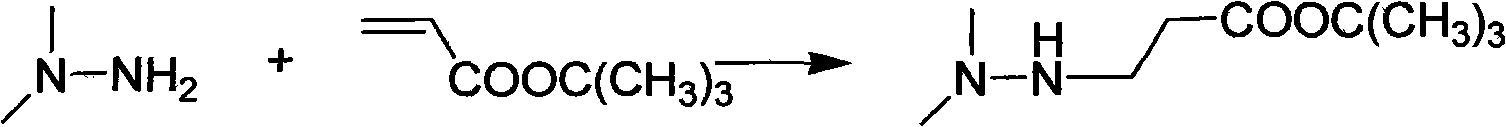

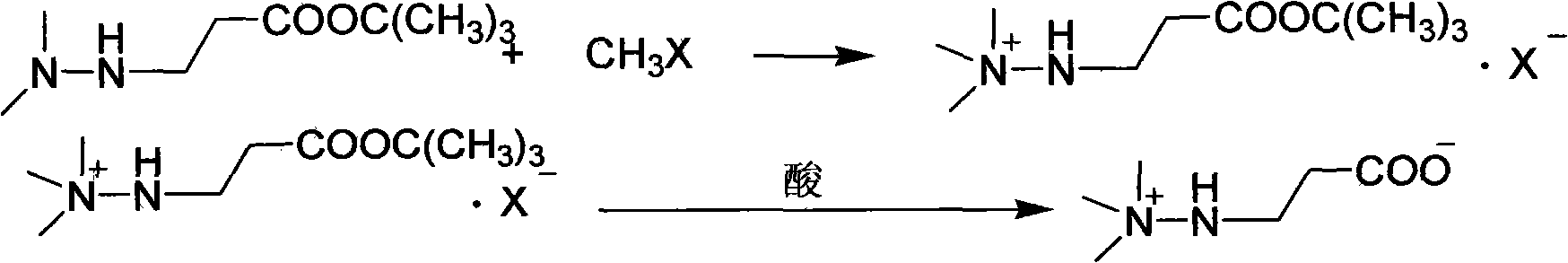

Method used

Image

Examples

Embodiment 1

[0029] Add 128 g (1 mol) of tert-butyl acrylate into a three-necked flask with mechanical stirring and dropping funnel, cool to 0°C, add 63 g (1.05 mol) of unsymmetrical dimethylhydrazine dropwise, drop it in 1.5 hours, and continue at the same temperature After stirring for 1 hour, 171.1 g of tert-butyl 3-(2,2-dimethylhydrazine)propionate was distilled under reduced pressure, with a yield of 91% and a content of 98.8%;

[0030] Dissolve the above distillation product in 200ml of ethanol, cool to 0°C, pass through 90.8g of methyl chloride for 1 hour, continue stirring at the same temperature for 1 hour, filter, wash with cold ethanol, and dry to obtain 3-(2,2,2- Trimethylhydrazine) tert-butyl propionate chloride 234.3g, yield 91.0%, content 99.1%;

[0031] Dissolve the above-mentioned tert-butyl ester chloride in 100ml of water, add 10ml of 50% hydrochloric acid, heat and reflux for 2 hours, remove water and acid under reduced pressure, add 300ml of chloroform to the residue, ...

Embodiment 2

[0033] Add 128 g (1 mol) of tert-butyl acrylate into a three-necked flask with mechanical stirring and dropping funnel, cool to 0°C, add 66 g (1.1 mol) of unsymmetrical dimethylhydrazine dropwise for 1.5 hours, and continue at the same temperature After stirring for 1 hour, 172 g of tert-butyl 3-(2,2-dimethylhydrazine) propionate was distilled under reduced pressure, with a yield of 91.5% and a content of 98.7%;

[0034] Dissolve the above distillation product in 200ml of ethanol, cool to 0°C, pass through 96g of methyl bromide for 1 hour, continue stirring at the same temperature for 1 hour, filter, wash with cold ethanol, and dry to obtain 3-(2,2,2-trimethyl hydrazine) tert-butyl propionate bromide 236.3g, yield 91.3%, content 99.1%;

[0035] Dissolve the above-mentioned tert-butyl ester bromide in 100ml of water, add 10ml of 50% hydrobromic acid, heat to reflux for 3 hours, remove water and acid under reduced pressure, add 300ml of ethyl acetate to the residue, and adjust w...

Embodiment 3

[0037] The preparation of 3-(2,2-dimethylhydrazine) tert-butyl propionate is the same as in Example 1, except for step 2 and step 3;

[0038] Dissolve the above distillation product in 200ml of ethanol, cool to 10°C, pass through 135.7g of iodomethane for 1 hour, continue stirring at the same temperature for 1 hour, filter, wash with cold ethanol, and dry to obtain 3-(2,2,2- Trimethylhydrazine) tert-butyl propionate iodide 275.7g, yield 91.8%, content 99.0%;

[0039] Dissolve the above-mentioned tert-butyl ester iodide in 100ml of water, add 10ml of 50% hydroiodic acid, heat to reflux for 3 hours, remove water and acid under reduced pressure, add 300ml of dichloromethane to the residue, adjust the pH to 7-8 with trimethylamine, Stir for 10 minutes, filter, wash twice with dichloromethane, and recrystallize the solid with 95% ethanol to obtain 108.2 g of the target product, with a yield of 88.7% and a content of 99.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com