Device for desalinating seawater by utilizing residual heat of tail gas exhausted by diesel engine

A diesel engine and seawater technology, which is applied in seawater treatment, general water supply conservation, water/sewage treatment, etc., can solve the problems of large primary energy consumption or secondary energy consumption, and achieve the effects of simple structure, convenient maintenance, and large temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

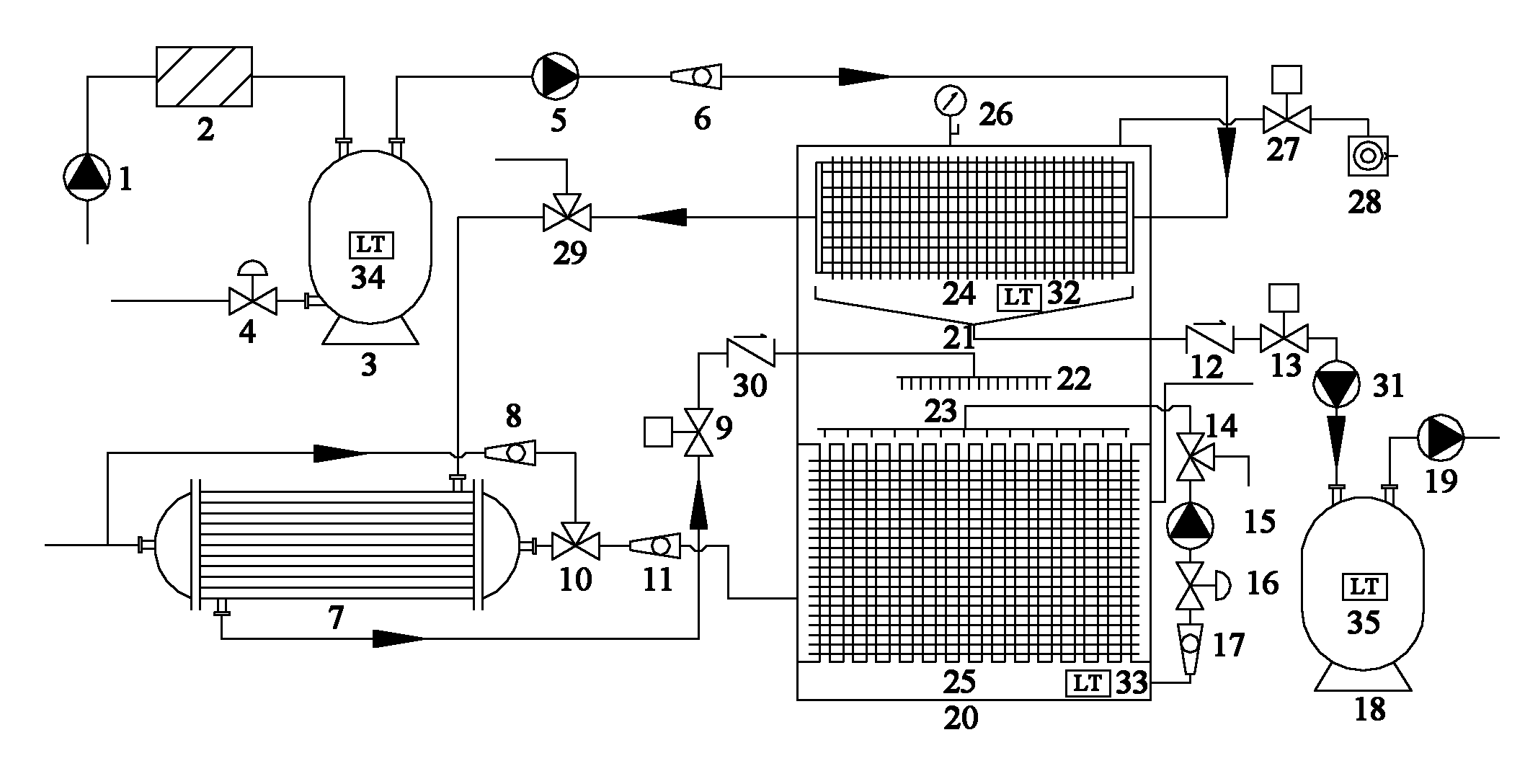

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation measures.

[0049] A seawater desalination device that utilizes the waste heat of diesel engine exhaust. Seawater is sent to the seawater pretreatment filter 2 by the No. 1 pump 1 through the pipeline, and then sent to the inlet of the seawater storage tank 3 through the pipeline. The outlet of the seawater storage tank 3 is fed by the No. 2 pump 5 Lead into the condenser 24 in the seawater desalinator 20 through pipeline;

[0050] The condenser 24 is connected to the seawater inlet port of the horizontal shell-and-tube heat exchanger 7 through the No. The valve 10 is connected and connected to the falling film evaporator 25 in the seawater desalinator 20;

[0051] The flue gas outlet pipeline of the horizontal shell-and-tube heat exchanger 7 is connected to the seawater desalinator 20 through the check valve 30, and is sprayed by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com