Internal combustion type wastewater treatment device with automatic temperature control rotating speed device

An automatic temperature control and wastewater treatment technology, applied in the direction of heating water/sewage treatment, general water supply saving, etc., can solve the problems of high wastewater treatment cost, large heat loss, large amount of fuel, etc., to reduce evaporation cost, less heat loss, Labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

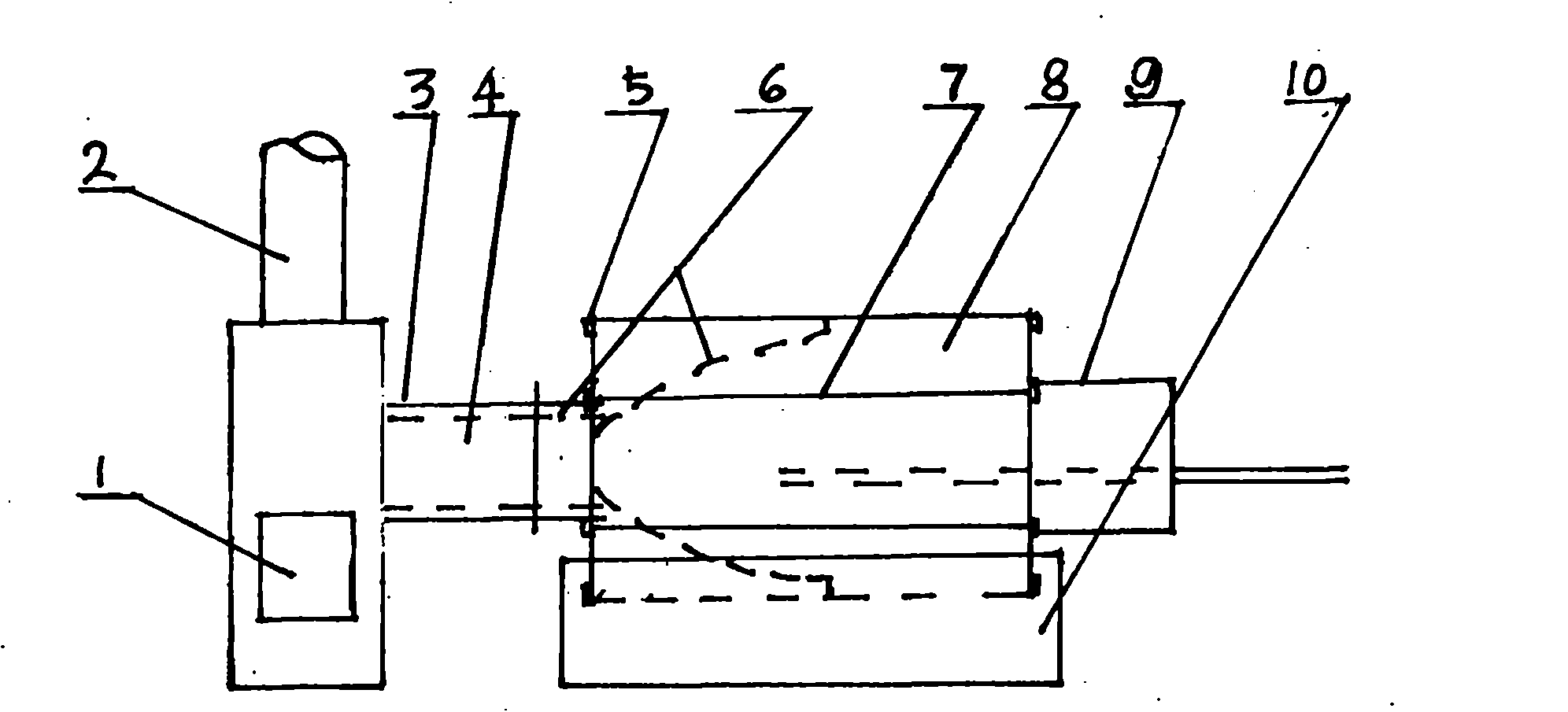

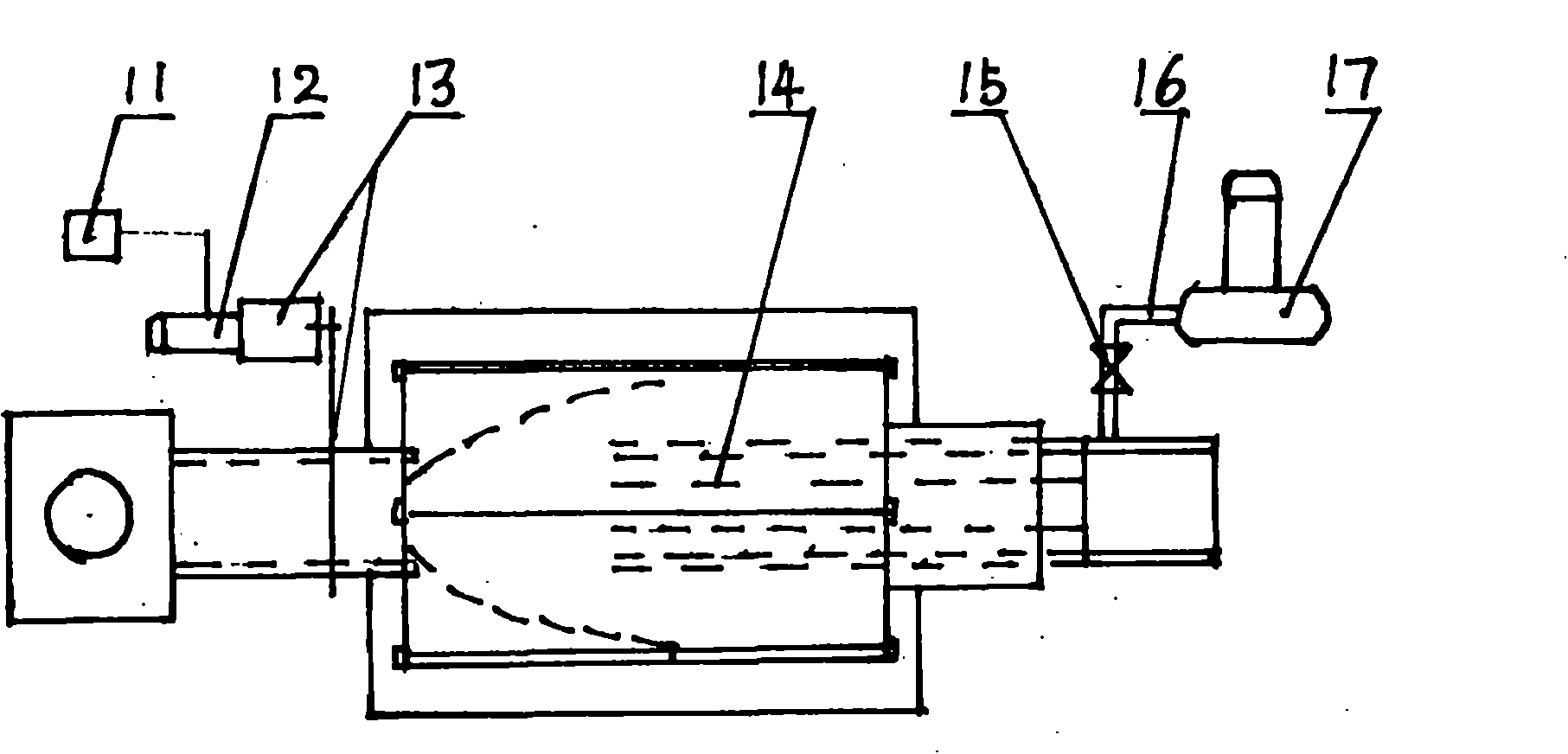

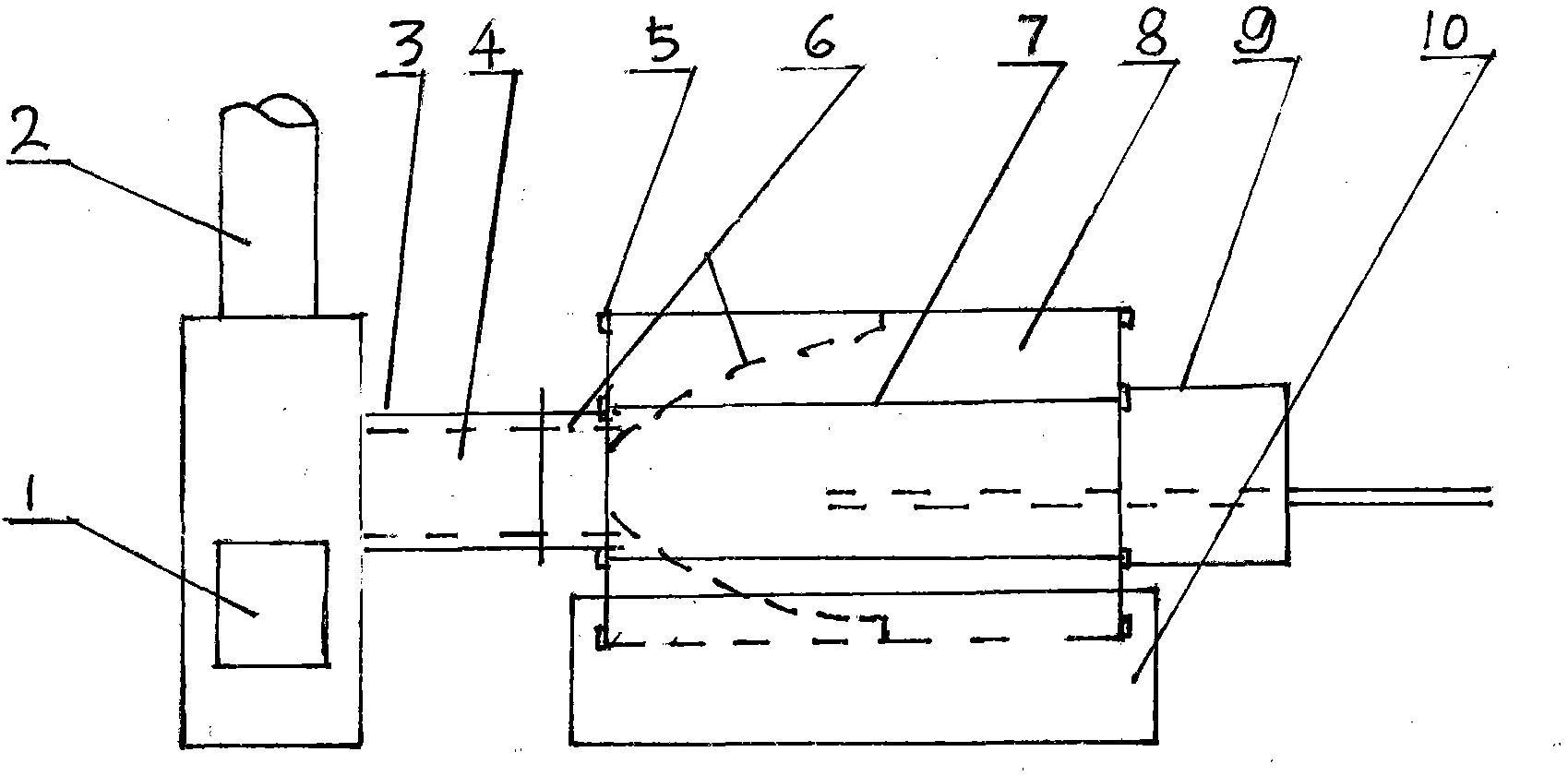

[0009] Let's talk about the production and installation process of the present invention with reference to the accompanying drawings:

[0010] 1. Make an evaporating cylinder with an inner hollow connected to the fuel pipeline and the ash outlet pipeline on both sides: first select titanium metal with acid and alkali corrosion resistance and good thermal conductivity to make an evaporating cylinder with an inner hollow and an opening at each end. A wiper made of the same material is installed on the surface of the cylinder; then the fuel inlet pipe and the ash outlet pipe are made of the same material, the size of the fuel inlet pipe and the ash outlet pipe matches the size of the opening of the evaporation cylinder, and then the same material is used in the evaporation cylinder A parabola-shaped dust scraper is installed in the end and the ash discharge pipe, and finally the opening in front of the evaporation cylinder is connected with the fuel inlet pipe, and the opening at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com